Inkjet print calibration using test patches and densitometer

An inkjet printing and imprinting technology, applied in printing devices, printing, electrical components, etc., can solve problems affecting the quality and consistency of printed images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a detailed description of preferred embodiments of the present invention with reference to the accompanying drawings, in which like numerals refer to like structural elements in each of the drawings.

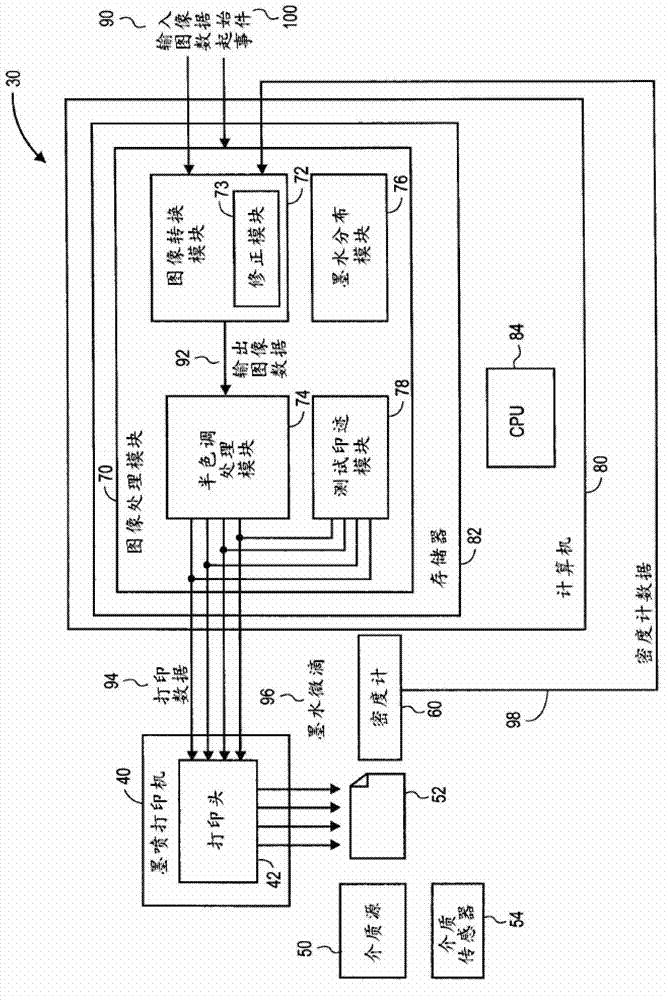

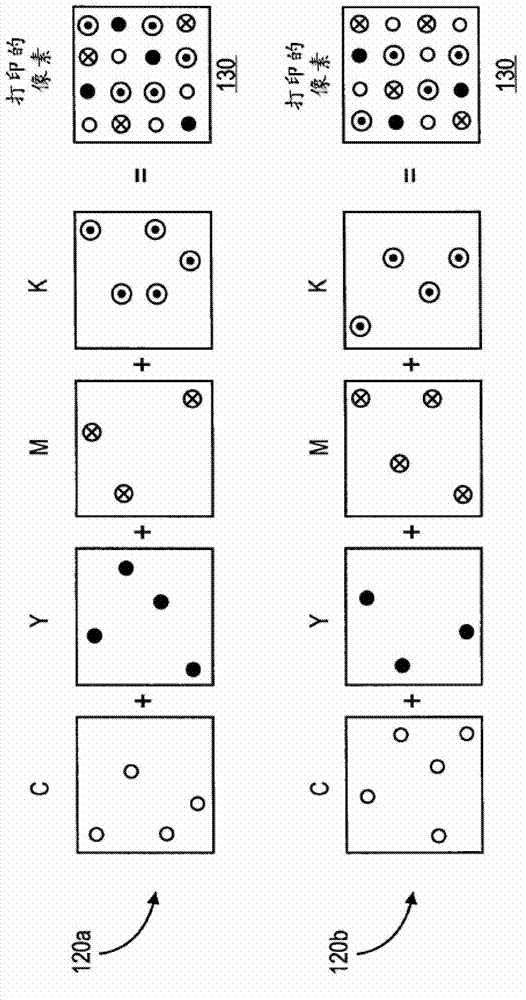

[0027]figure 1 To generally illustrate a block diagram and schematic diagram of an example of an inkjet printing system 30 configured to print a test blot and use a densitometer to measure the The density of the print compensates for factors that would otherwise impair image quality in a manner that modulates the ejection of ink droplets from the printhead.

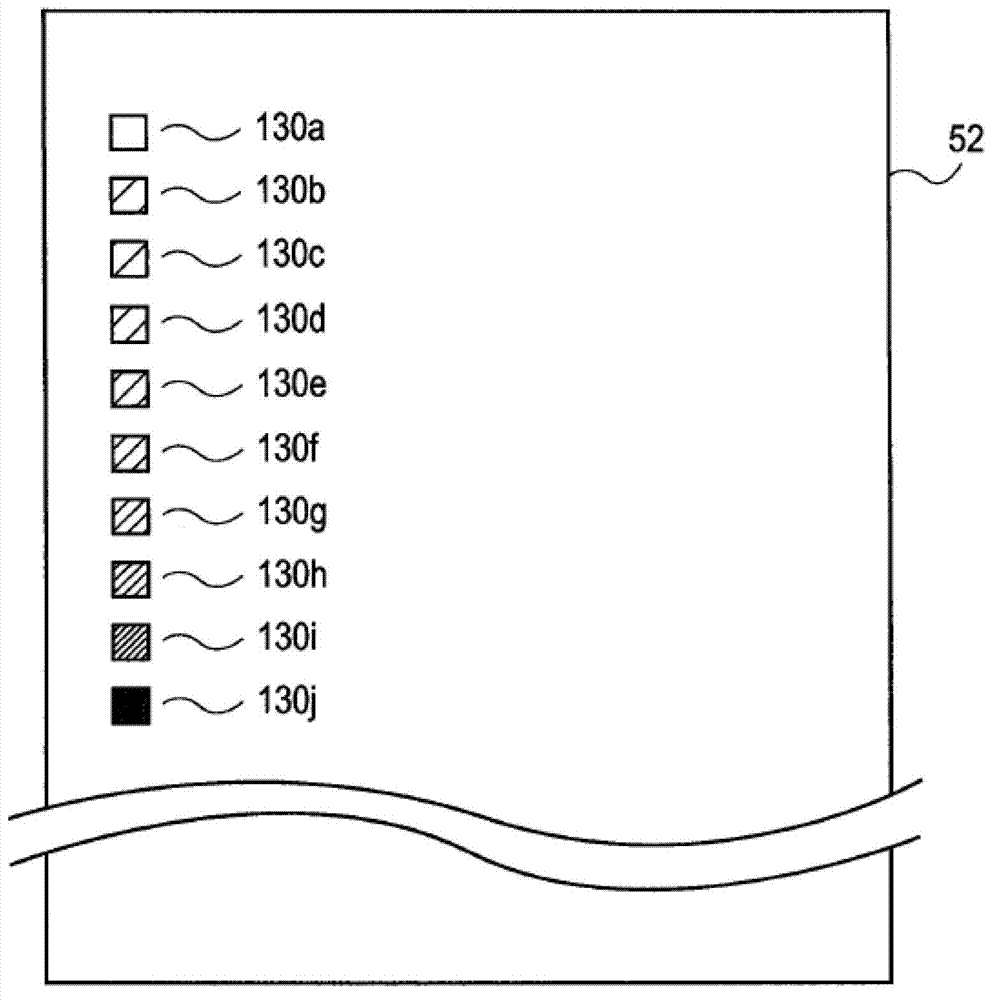

[0028] according to figure 1 According to an embodiment of the present invention, the inkjet printing system 30 includes: an inkjet printer 40 having a printhead 42 ; a media source 50 providing a plurality of sheets of imaging media 52 ; a densitometer 60 and an image processing module 70 . According to one embodiment, the media source 50 includes a cassette that provides the plurality of transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com