Concave axicon capable of producing long distance non-diffraction beams

A non-diffracted light, long-distance technology, used in lenses, optics, optical components, etc., can solve the problems of scarce and expensive materials, low conversion efficiency, high price, etc., and achieves high light damage threshold, easy and high component processing. The effect of practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and principle of the concave conical lens of the present invention will be further described in detail in conjunction with the accompanying drawings and examples.

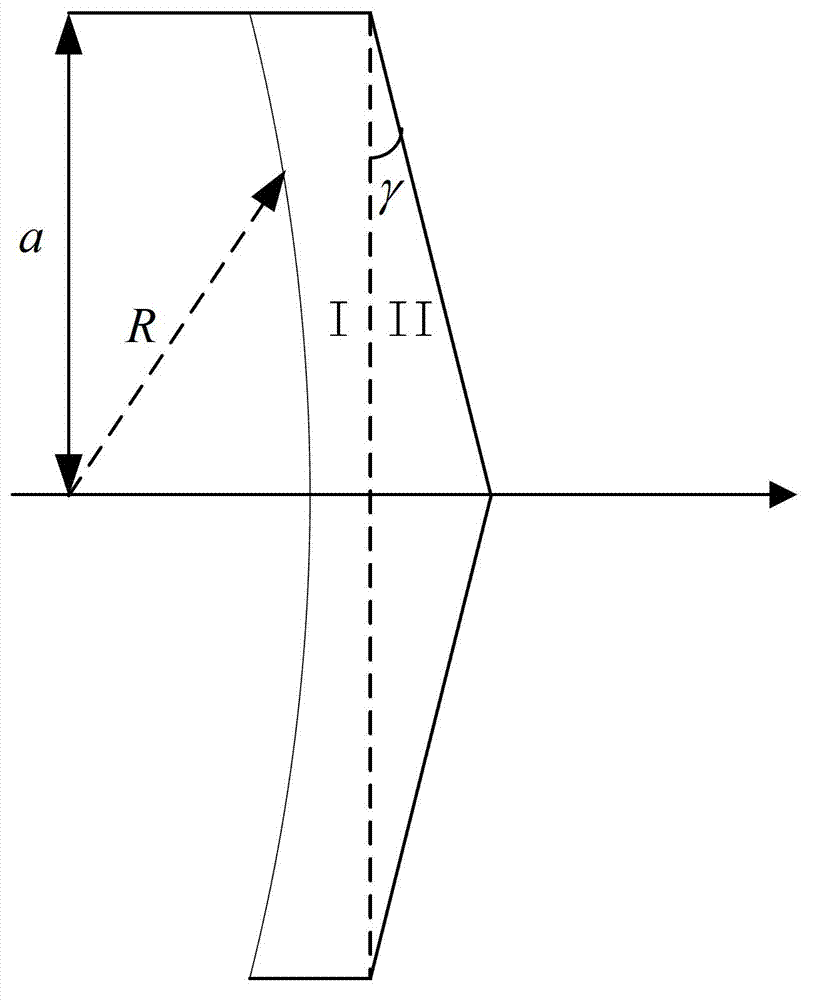

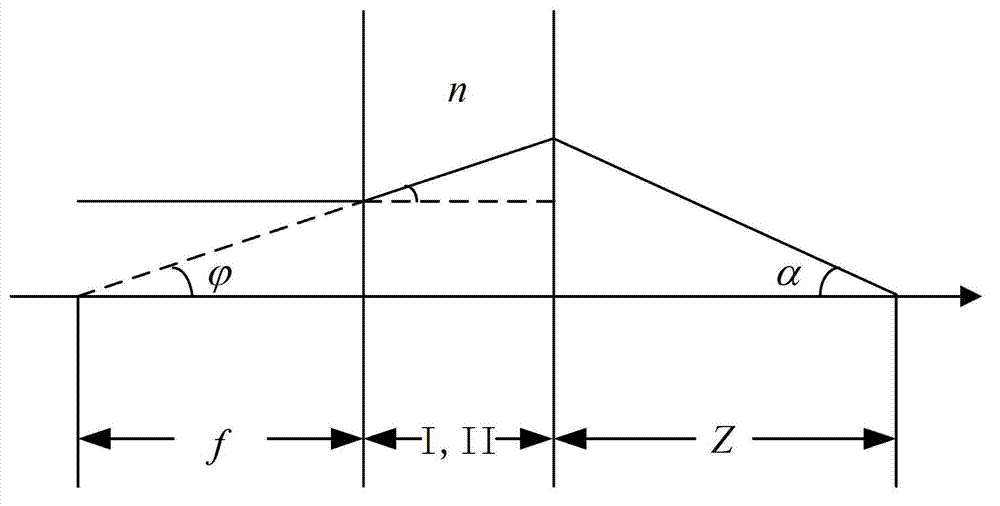

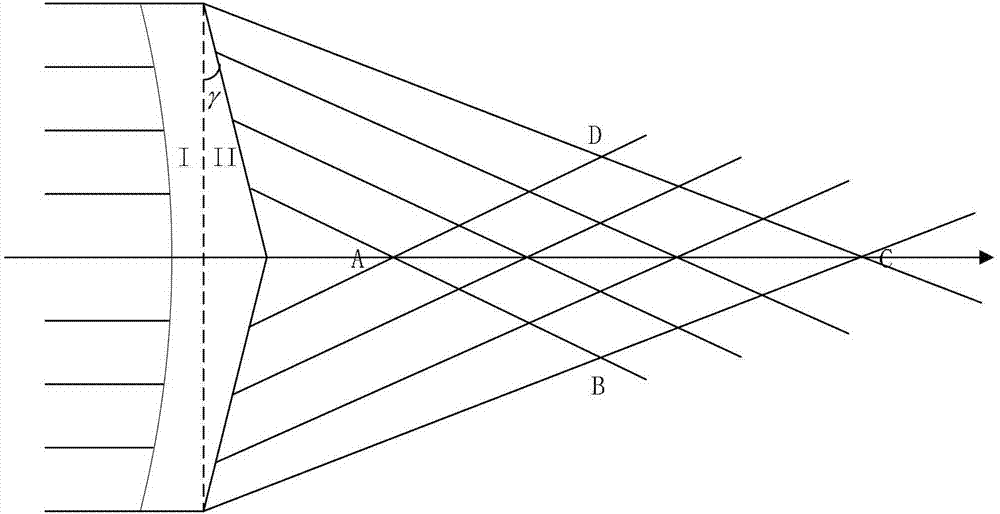

[0015] A kind of concave aconic lens that produces long-distance non-diffraction light of the present invention, as figure 1 As shown, there is an axicon with a cone angle of γ, a base radius of a, and a refractive index of n. This axicon is divided into a cylindrical part I and a conical part II along its axial direction, and the cylindrical part I is adjacent to the conical part II. One end is inside, and the other end is outside, and the outer bottom surface of this cylinder part I is the concave spherical surface shape that the radius of curvature of this axicon axis is the center and is R.

[0016] The concave aconic lens of the present invention is processed on the basis of the traditional axicon. Take a traditional axicon with cone angle γ, base radius a, and refractive index n, divide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com