A strain type linear bidirectional large displacement sensor and its detection method

A large-displacement, strain-type technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve the problems of not too large displacement, long production cycle, high production cost, high sensitivity and precision, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described below.

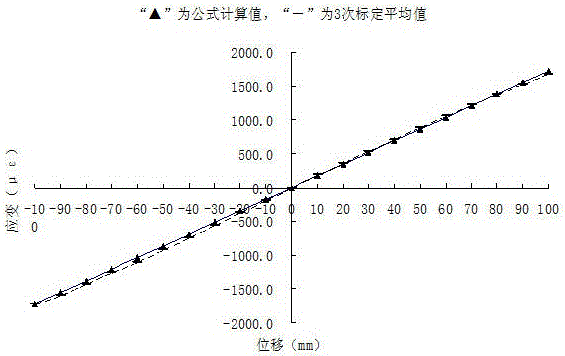

[0047] The theoretical basis of the strain type linear bidirectional large displacement sensor of the present invention:

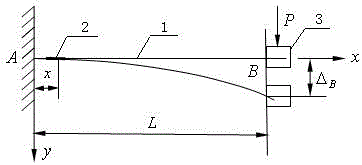

[0048] The cantilever beam strain displacement sensor is the simplest structural form of the displacement sensor. Its principle is to paste the strain gauge on the elastic element and connect it to a certain bridge. When the elastic element is deformed by force, the bridge will have an electrical signal. Output, the application of measuring instruments can measure the required parameters.

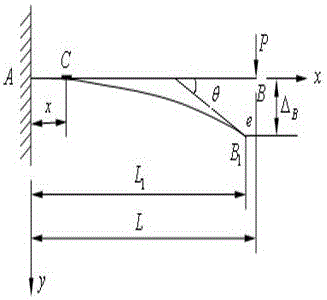

[0049] as attached figure 2 is the calculation diagram of the rectangular cantilever beam elastic element, The axis is along the axis direction of the cantilever beam before deformation, Axis is the direction of vertical displacement of the beam. Deformed beam in The projection on the axis is . C is the distance from the fixed end Attached strain gauges. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com