Bridge loading test deflection testing instrument

A technology of load test and test instrument, which is applied in the direction of instrument, elasticity test, machine/structural component test, etc. It can solve the problems of slow test process, limitation of level accuracy, affecting test efficiency, etc., and achieves convenient level adjustment and positioning. Convenience and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

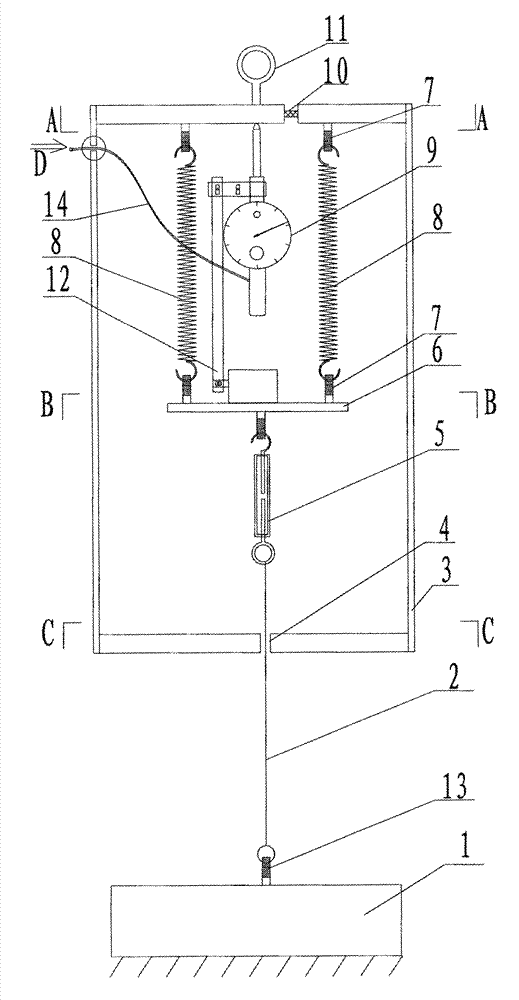

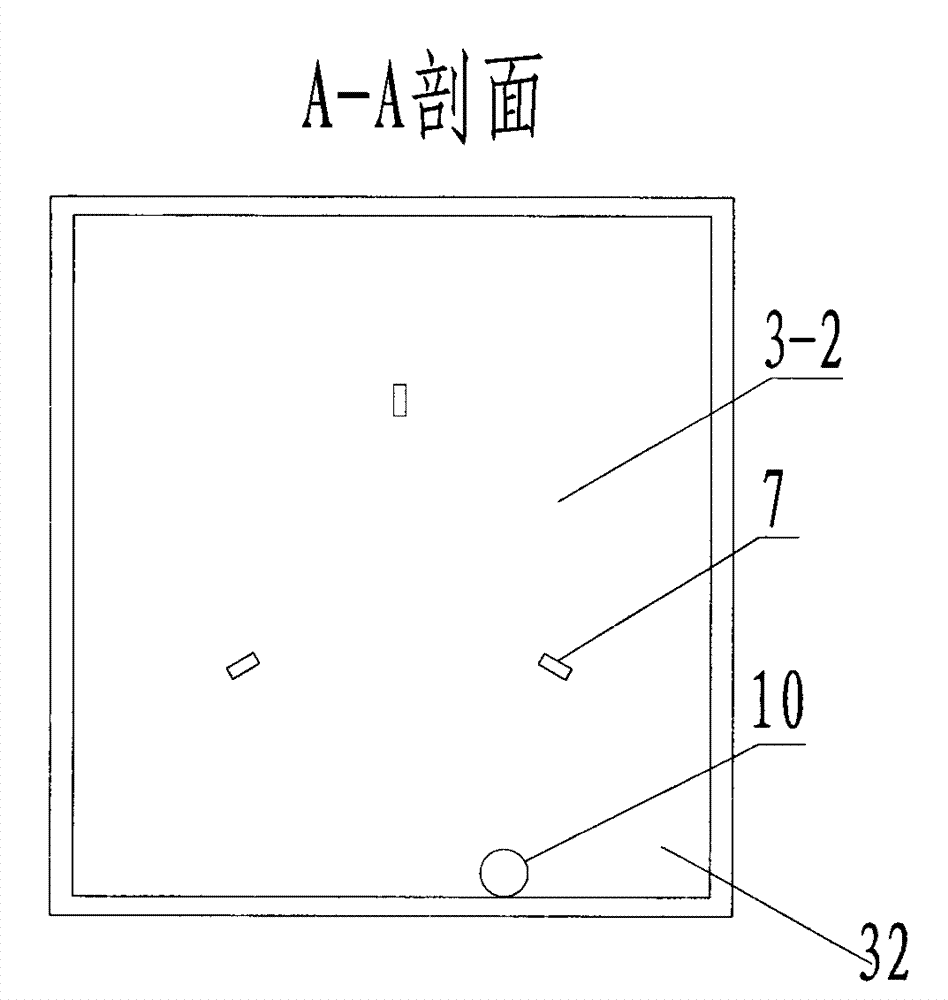

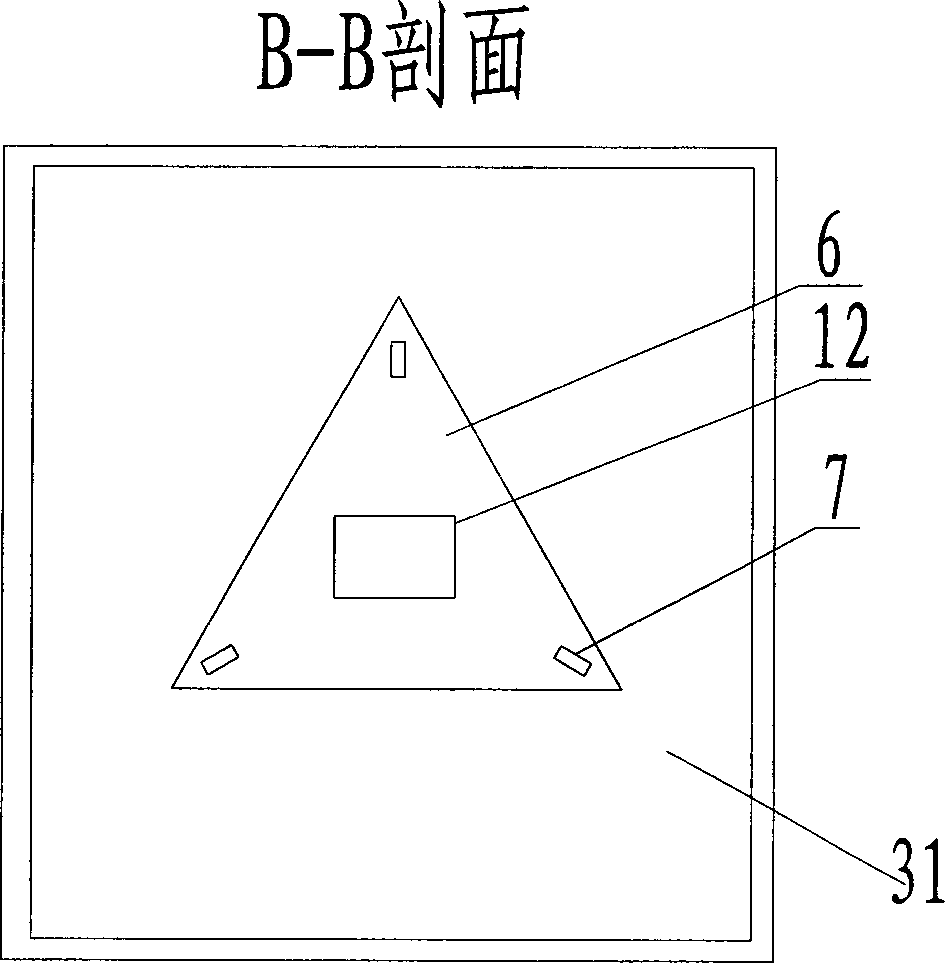

[0036] Such as Figure 1 to Figure 4 As shown, the invention includes an instrument box 3, a level 10 installed on the top surface of the box body 3 and measuring the levelness of the top surface of the box body, three springs 8 fixedly suspended on the top surface of the box body 3, connecting The test platform 6 at the lower end of the spring 8, the test instrument support 12 fixed above the test platform 6, the deflection test instrument fixed on the test instrument support 12, the turnbuckle for adjusting the elongation of the spring 8 before the deflection test 5. During the deflection test process, the deflection test rope 2 is always in a vertical state under the traction of the spring, and the counterweight 1 placed on the ground. The box body 3 has a side opening 15 .

[0037] The test platform 6, the spring 8, the test instrument support 12, the test instrument, the turnbuckle 5, and the partial deflection test rope 2 are all placed inside the box body 3.

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com