Continuous operation rolling over docking type tunnel lining formwork trolley

A formwork trolley and docking technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of wrong platform, insufficient concrete strength, and it is difficult to avoid wrong platform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

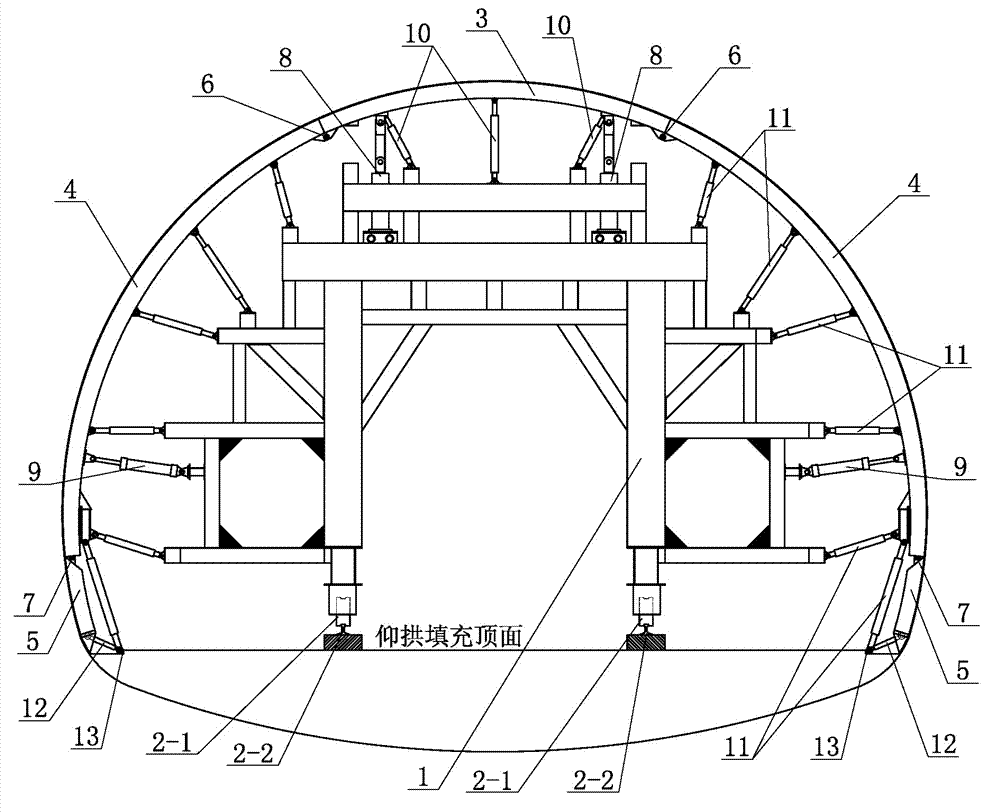

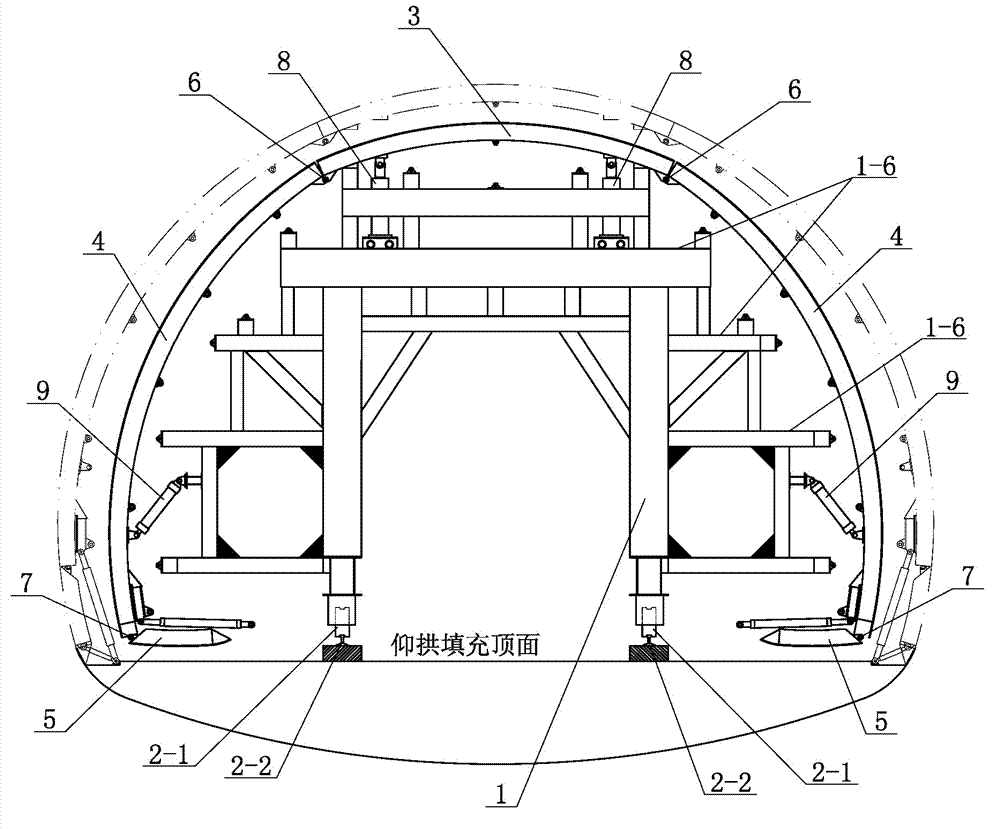

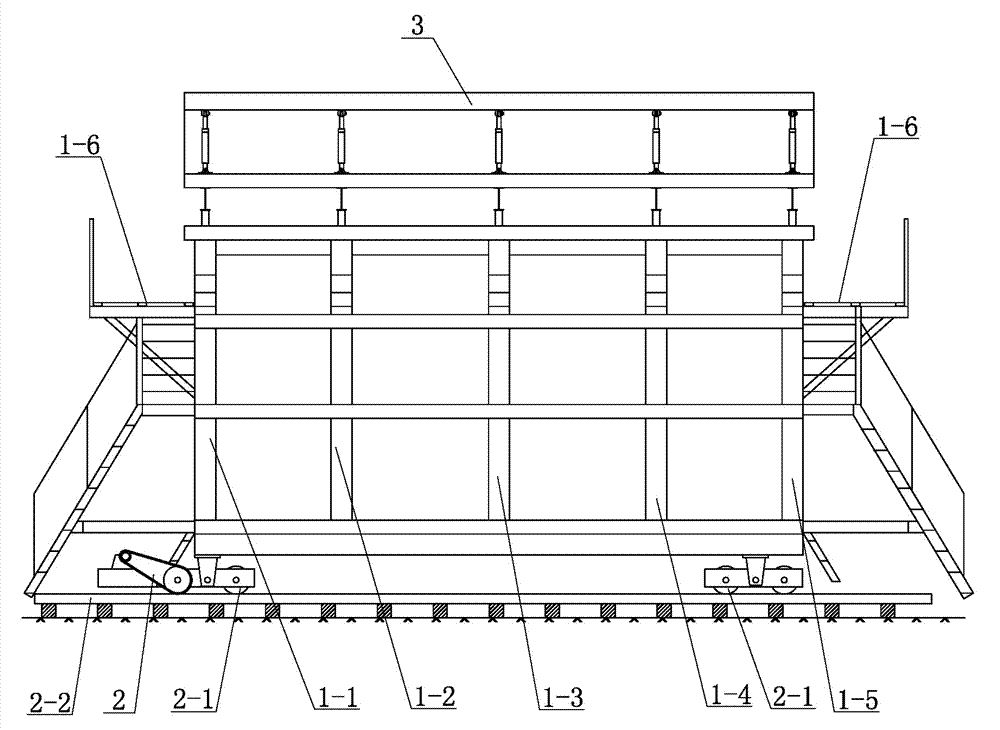

[0031] Such as figure 1 , figure 2 , image 3 , a continuous operation overturning butt joint type tunnel lining formwork trolley, which performs concrete pouring construction operations for the secondary lining of the tunnel, including a platform frame 1, a traveling device 2, a hydraulic drive device, a supporting screw group, and a formwork group; the traveling device Installed on the bottom of the platform frame, the traveling device drives the platform frame to advance along the direction of tunnel excavation; the hydraulic drive device and the supporting screw group are installed on the platform frame; three sets of the Template group, the outer contour size of the shrunk template group is smaller than the inner contour size of the expanded template group, and can pass through the expanded template group (such as figure 2 shown), each template group can be connected to the platform frame through the supporting screw group and the hydraulic drive device, the template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com