Translation type turnout junction used for drawing distant controlled auxiliary transport equipment by mining rope

A technology of auxiliary transportation and rope traction, which is applied in the field of translational turnouts, can solve problems such as weakening of strength, and achieve the effect of reasonable structure, complete functions, and scientific and reasonable conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

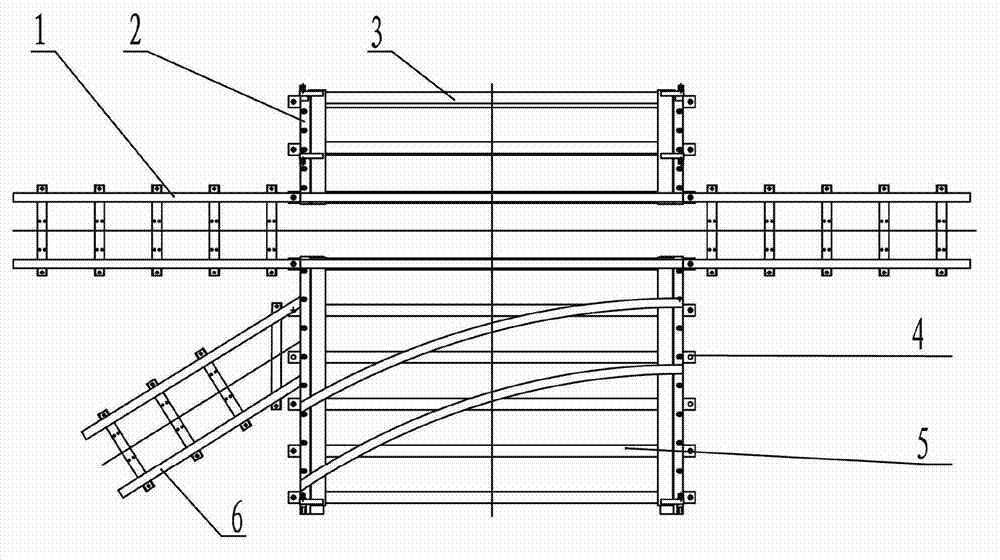

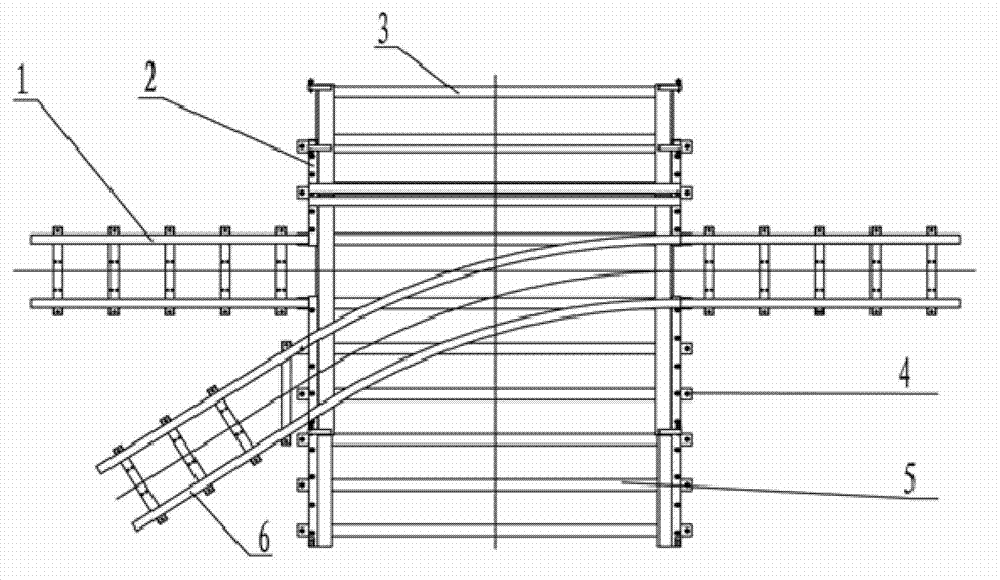

[0010] As shown in the accompanying drawings, a translational turnout used in mine rope traction remote control auxiliary transportation equipment mainly includes butt straight rail 1, short fixed rail 2, short moving rail 3, long fixed rail 4, long moving rail 5, Inclined straight rail 6, one side of the gap between the two butt straight rails 1 is the short fixed rail 2, the other side is the long fixed rail 4, the inclined straight rail 6 is located on one side of the long fixed rail 4; There is a chute, the short moving rail 3 is installed in the chute on the short fixed rail 2, there is a chute on the long fixed rail 4, the long moving rail 5 is installed in the chute on the long fixed rail 4, and the short moving rail 3 There is a connecting straight rail whose length matches the length of the gap between the two butt straight rails 1, and the long moving rail 5 has a connecting straight rail whose length matches the gap length between the two butt straight rails 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com