A Pneumatic Clamping and Unloading Mechanism for Automatic Welding

A technology of a pneumatic clamping and unloading mechanism, applied in the field of auto parts production devices, can solve the problems of easy dislocation, easy scratches on the surface, large production output, etc., and achieves the effects of sensitive action, reduced production accidents, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

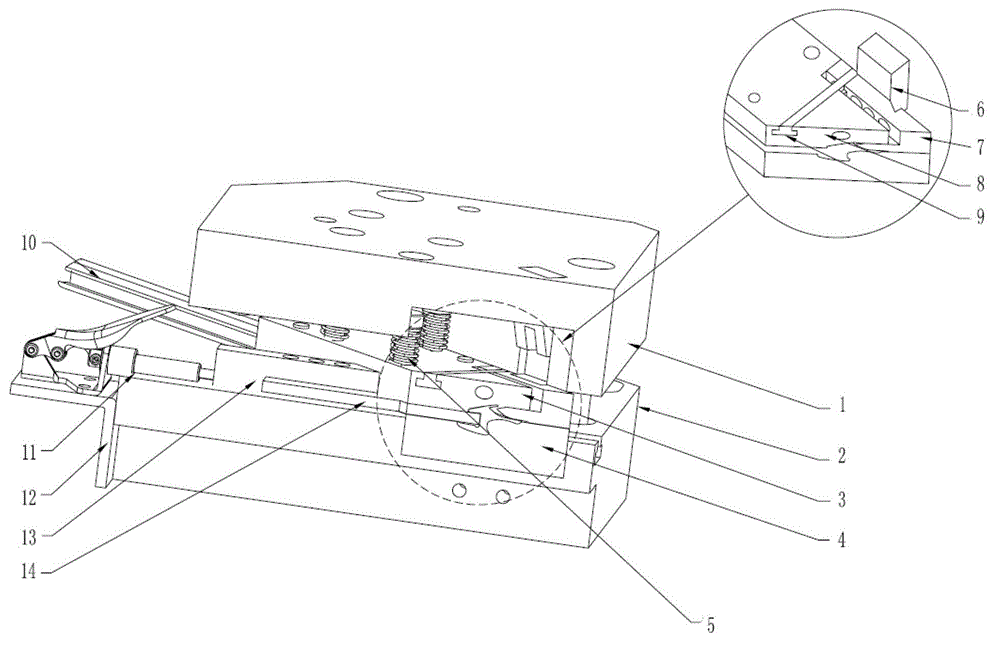

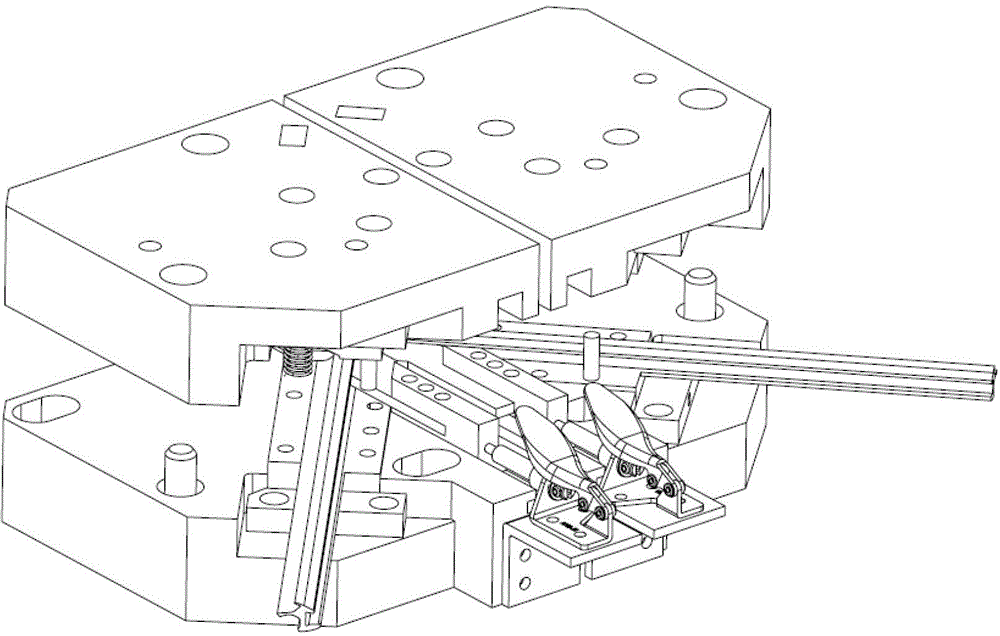

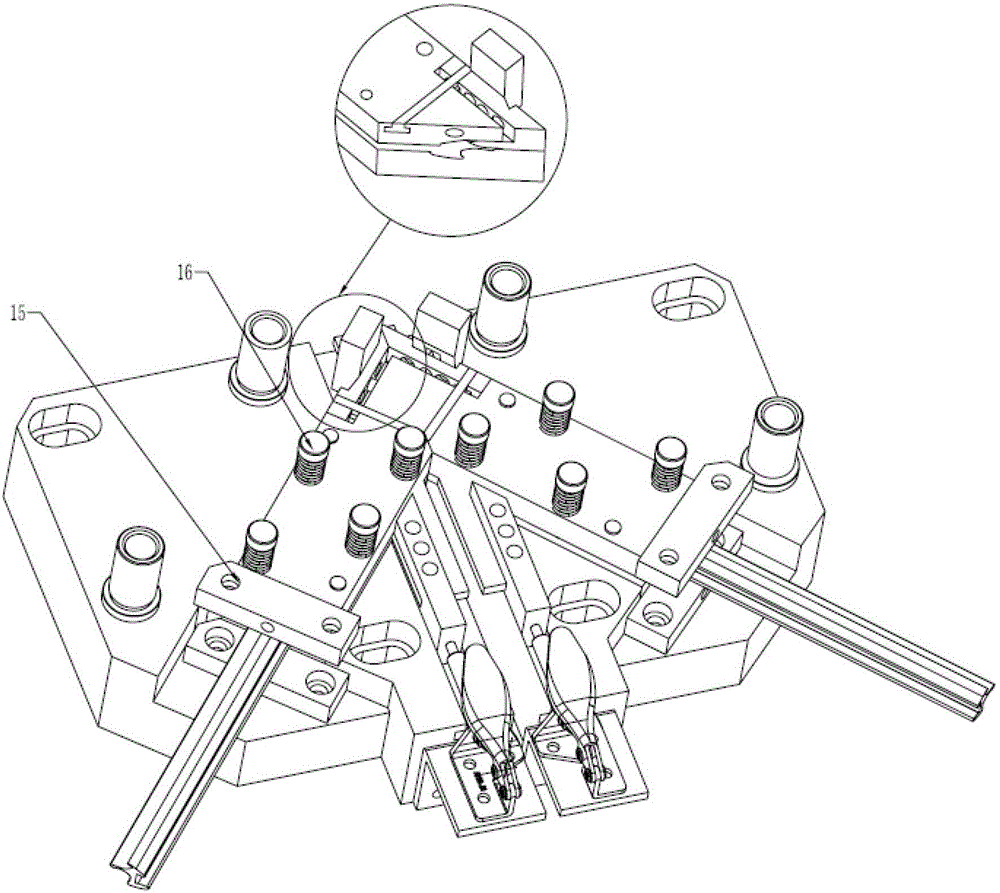

[0021] Such as Figure 1 to Figure 6 As shown, an automatic welding pneumatic clamping and unloading mechanism includes an upper template 1, a lower template 2, a first lower mold 3, a second lower mold 4, a flat wire coil spring 5, a block 6, and a clamping block 7 , pin 8, slider 9, product 10, quick chuck 11, quick chuck support block 12, product clamping block fixing plate 13, product clamping block 14, limit block 15, discharge screw 16, the Below the upper template 1 is the lower template 2. A pair of quick chuck support blocks 12 are installed and fixed in the middle of the front side of the lower template 2. Each quick chuck support block 12 is connected and fixed with a quick chuck 11. The output end of the quick chuck 11 is connected to the The product clamping block fixing plate 13 in the front is connected and fixed, the product clamping block 14 is installed in the guide groove of the product clamping block fixing plate 13, and the free end of the product clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com