Analog semi-rigid underlying structure temperature shrinkage fracture testing method and device

A technology of semi-rigid base and test method, which is applied in the field of tests and devices for simulating temperature shrinkage and fracture of semi-rigid base structures, can solve the problems of inability to simulate the actual boundary conditions of the base, and the workload is large, so as to save the workload and achieve a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

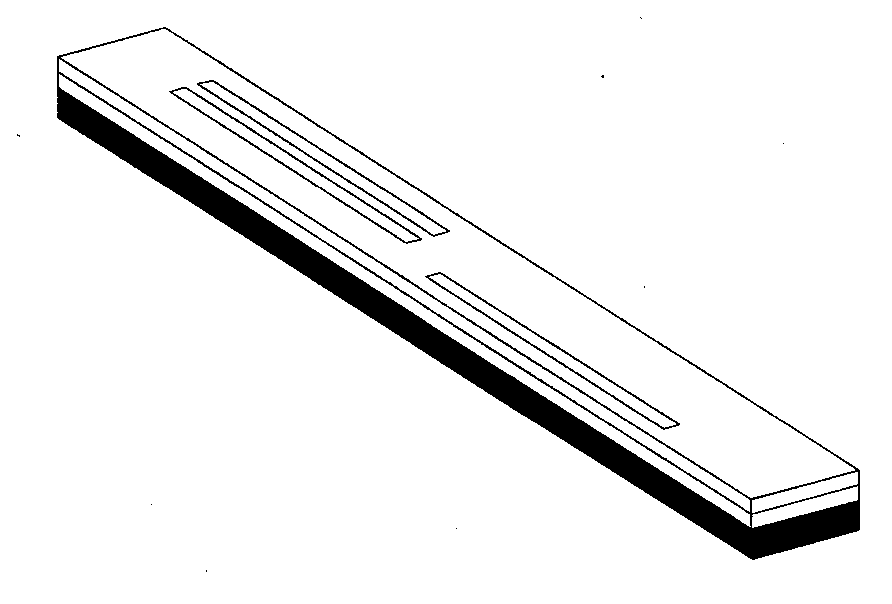

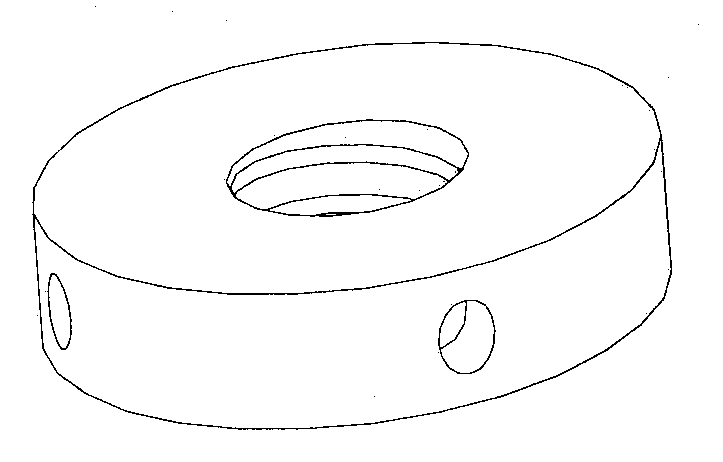

[0020] The test method for simulating semi-rigid base structure thermal shrinkage fracture of the present invention: firstly carry out the making of test piece, select material according to the selection method of material of the present invention, select plexiglass plate and rubber tire as the material of simulating base and soil foundation. According to the principle of similarity, the thickness and width of the semi-rigid base structure and the plexiglass plate are proportional, and the strain gauges (9) are respectively pasted on the two sides of the plexiglass plate of the simulated base layer, and then the two plexiglass plates are connected with glue. together. After bonding, cut a section of tire and stick it on one side of the two boards as a material for simulating the soil foundation. Then the prepared test piece (10) is clamped on the device by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com