Multifunctional split-type caterpillar drilling machine for coal mine

A multi-functional, split-type technology, applied in the direction of drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of slow relocation speed, incomplete function, high labor intensity, etc., to improve comfort and safety, Low labor intensity of workers and good process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings:

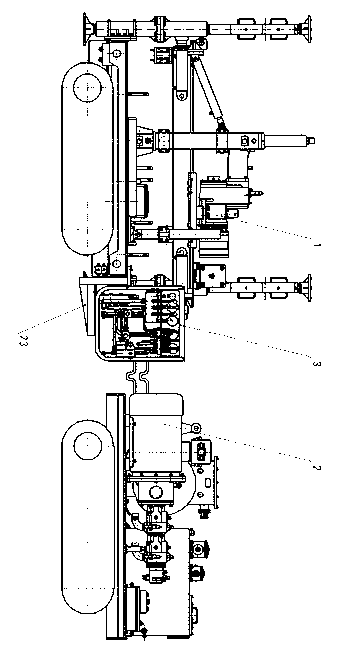

[0023] Such as figure 1 As shown, the present invention includes a drill truck 1, a pump truck 2, and a console 3. The drill truck 1, pump truck 2 and the console 3 are connected by high-pressure hoses. The console 3 is fixed to the drill by a bracket 23 during transportation. On the vehicle 1, the overall structure of the drilling rig of the present invention is a crawler split type.

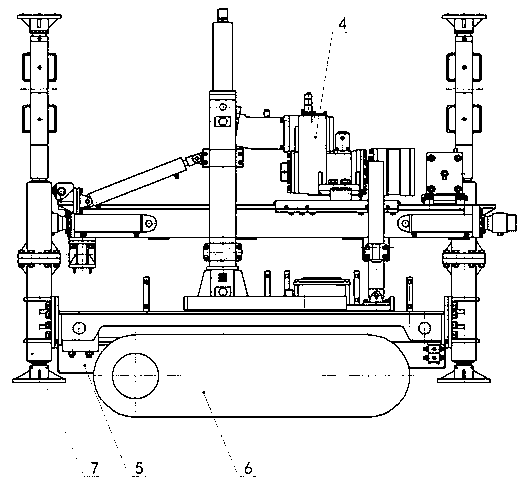

[0024] Such as figure 2 As shown, the drill rig 1 includes a main engine 4, a drill rig console 5, a crawler car body 6 and a stabilizing device 7, which is the main actuator of the rig. The drill rig console 5 is arranged in the middle of the rear side of the crawler car body 6. .

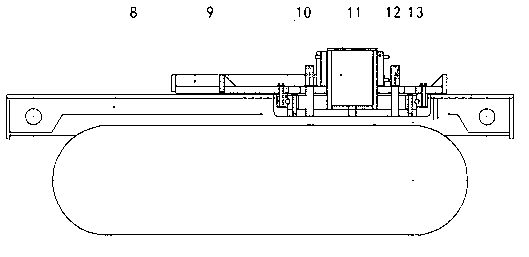

[0025] Such as image 3 As shown, the crawler car body 6 includes a car body platform 8 and a slewing platform 9. The car body platform 8 and the slewing platform 9 are connected by a slewing bearing 10, which can rotate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com