Bottom forming machine of square bottom paper bag

A bottom-hooking machine and paper bag technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as difficult quality assurance, unstable work, and low work efficiency, and achieve high production efficiency, compact structure, and light weight. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

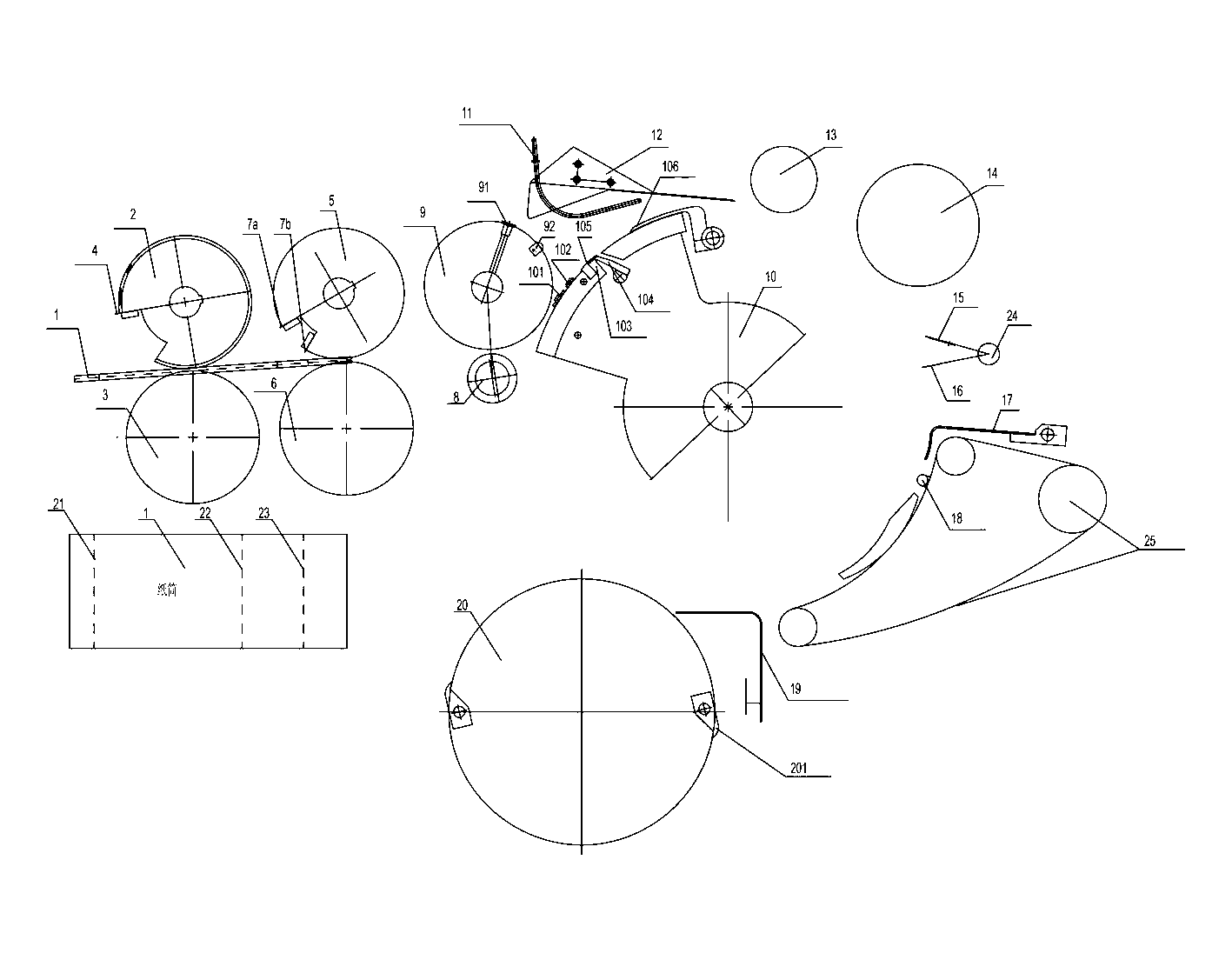

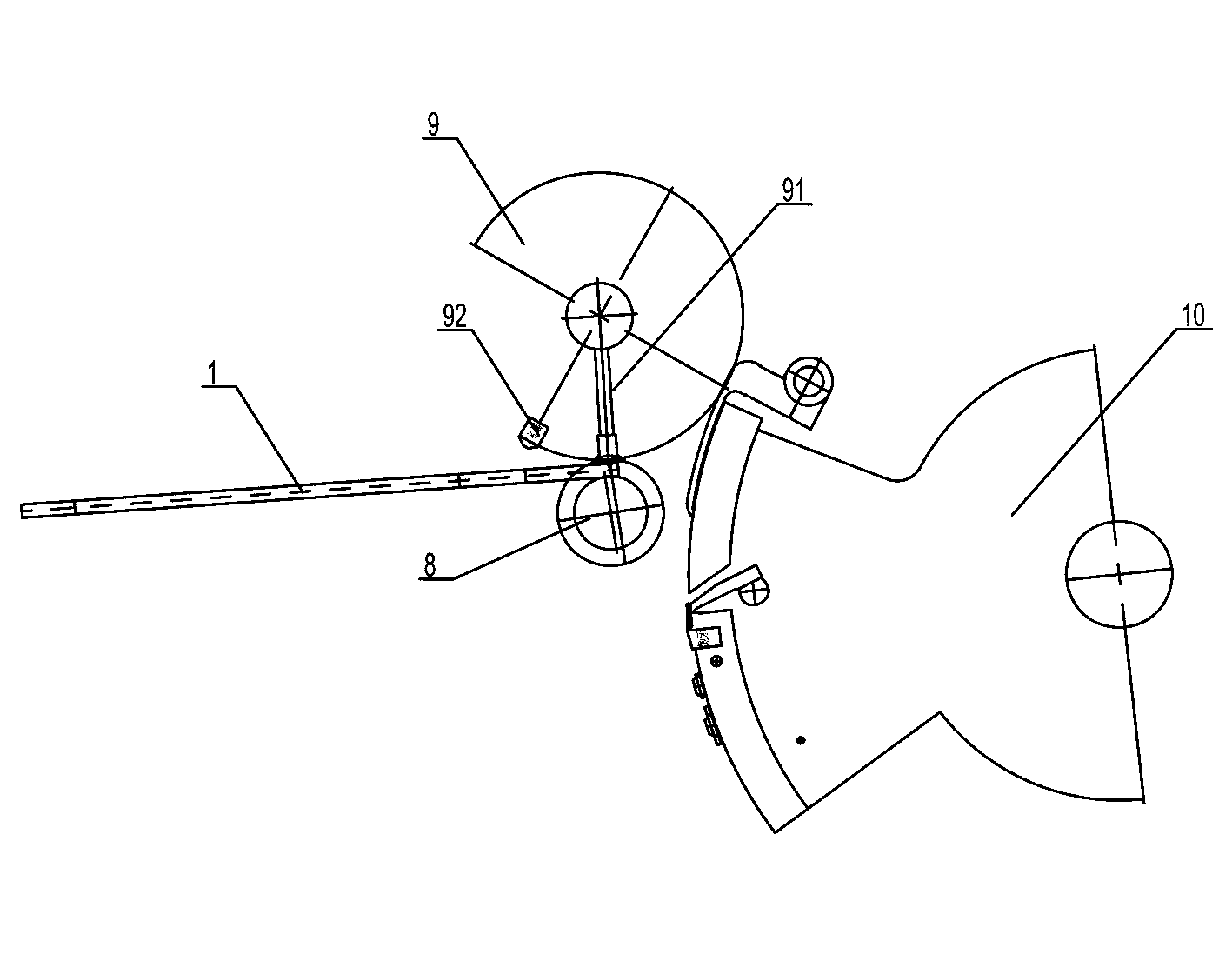

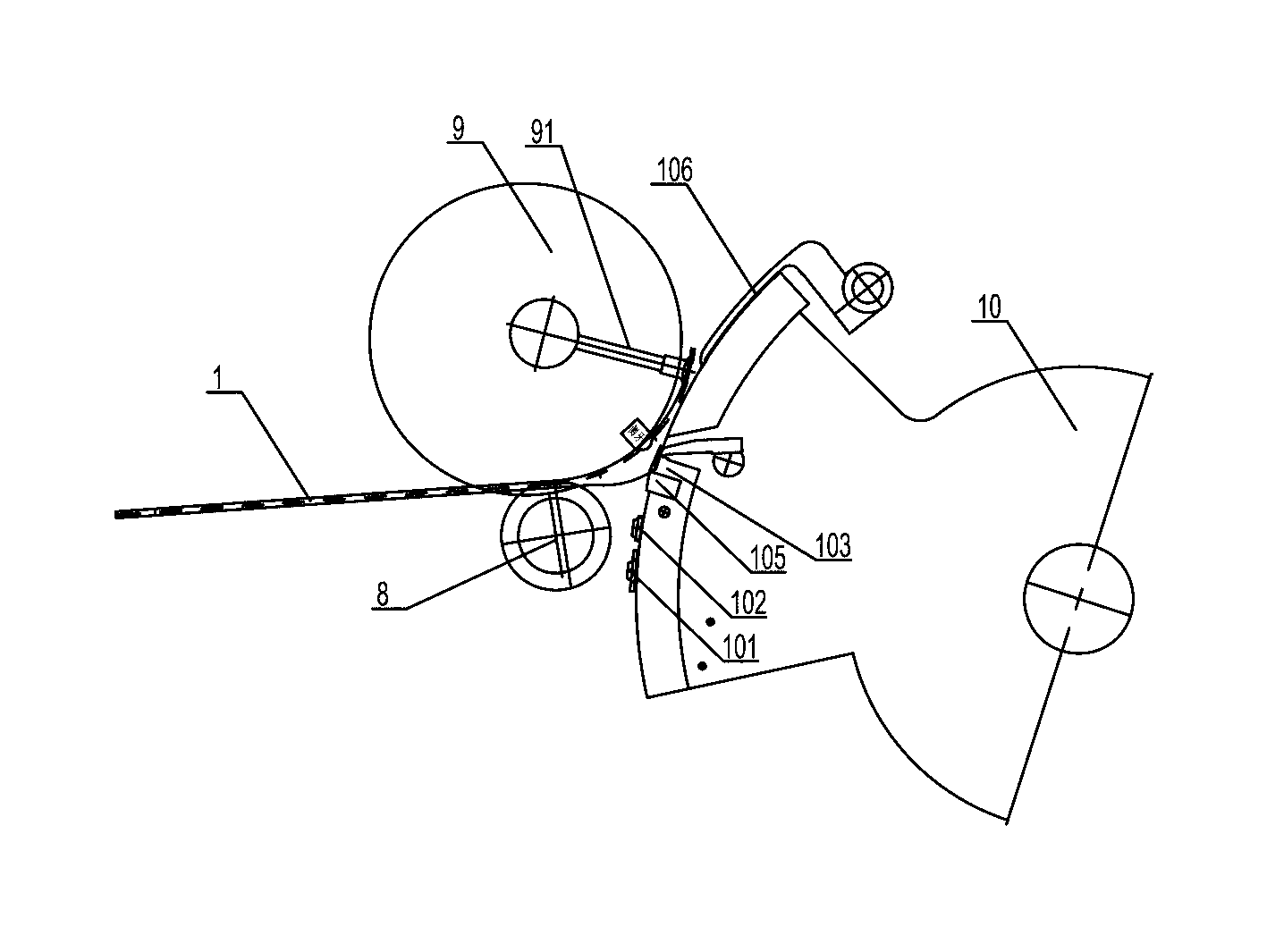

[0012] Such as figure 1 In the illustrated embodiment, a bottom-hooking machine for a square-bottomed paper bag includes a bag mouth turning and creasing part, a bag bottom turning and creasing part, a bottom pulling forming part, a bag bottom forming part, a bottom sealing part and a predetermined working procedure to drive The big rollers 10 that the above-mentioned parts operate synchronously; the folding and creasing part of the pocket is composed of the upper and lower folding rollers 2 and 3, and the upper folding roller 2 is provided with the first roller for pressing out the folding and creasing 21 of the pocket. Crimping knife 4; the folding and creasing part at the bottom of the bag is composed of upper and lower bag bottom sealing line pressure rollers 5 and 6, and the upper bag bottom sealing line pressure roller 5 is provided with the first bag bottom sealing pressure line 22, the second The second and third crimping knives 7a, 7b of the second bag bottom sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com