Ball screw pair-driven clamping mechanism

A technology of ball screw pair and mold clamping mechanism, which is applied in the field of mold clamping mechanism driven by ball screw pair, can solve the problems of low control precision, difficult maintenance, easy wear, etc., and achieve high control precision, prolong service life, and positioning accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

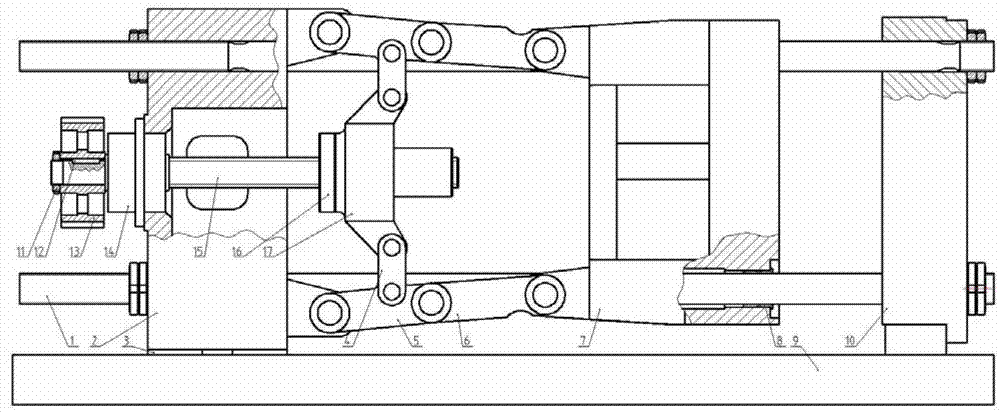

[0014] Such as figure 1 and figure 2 As shown, the clamping mechanism of the ball screw pair transmission of the present invention includes: four pull rods 1, tail plate 2, two toggle mechanisms, movable template 7, head plate 10, synchronous pulley 13, screw bearing housing 14, Ball screw 15, ball nut 16, thrust seat 17.

[0015] Corresponding four tie rod holes are provided on the head plate 10, the movable template 7 and the tail plate 2. Such as image 3 shown. One end of four pull rods 1 is all fixed on the head plate 10, and the other end is fixed on the tail plate 2 after passing through the pull rod holes of the movable formwork 7. Four pull rods 1 fix the distance between the head plate 10 and the tail plate 2, and are used for the motion guidance of the movable template 7. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com