Mop

A mop and roller technology, applied in the field of mops, can solve the problems of stains left on the surface, inability to reciprocate mopping, stains, etc., achieve good erasing, reduce the number of times to clean the mop, and increase friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

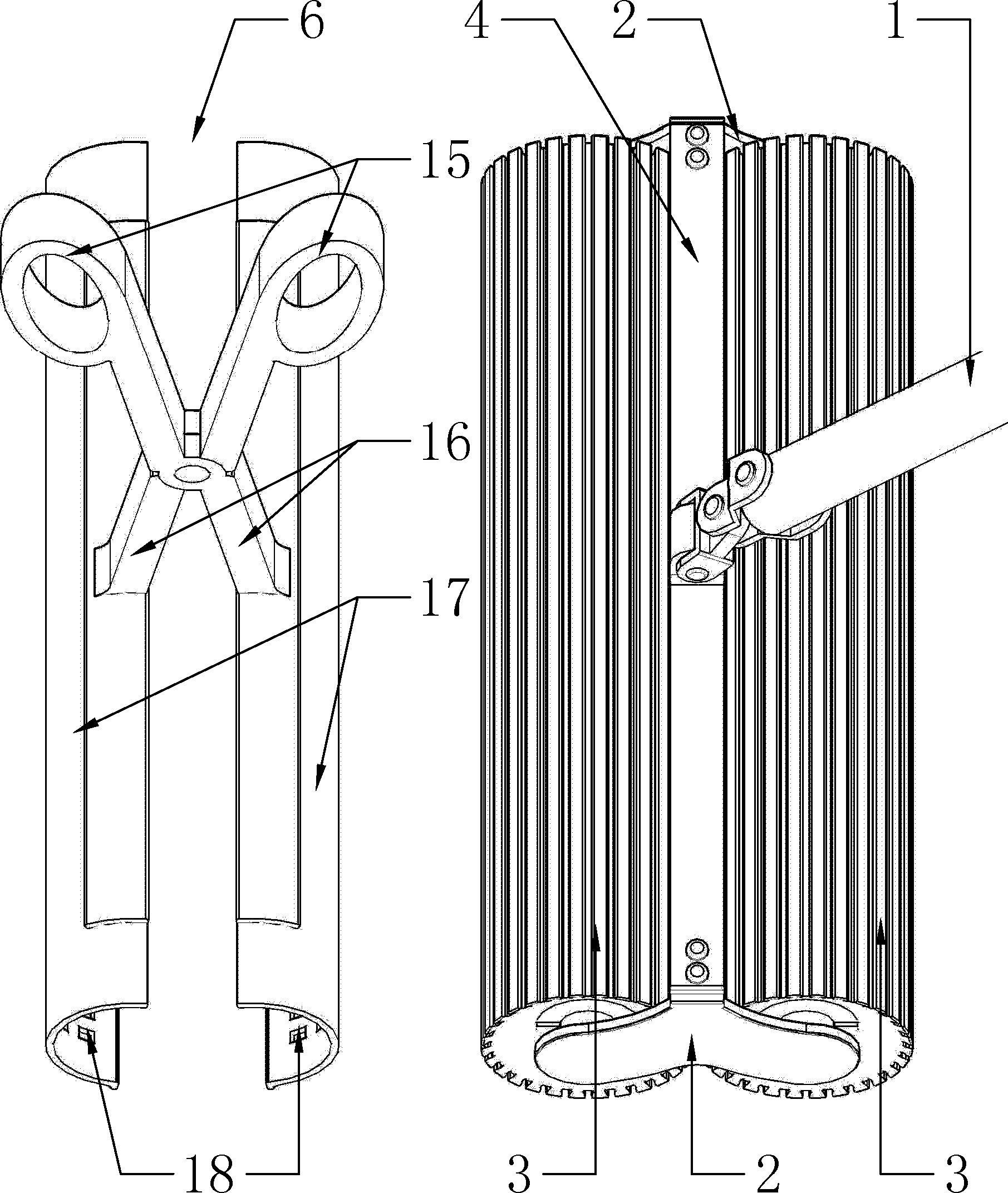

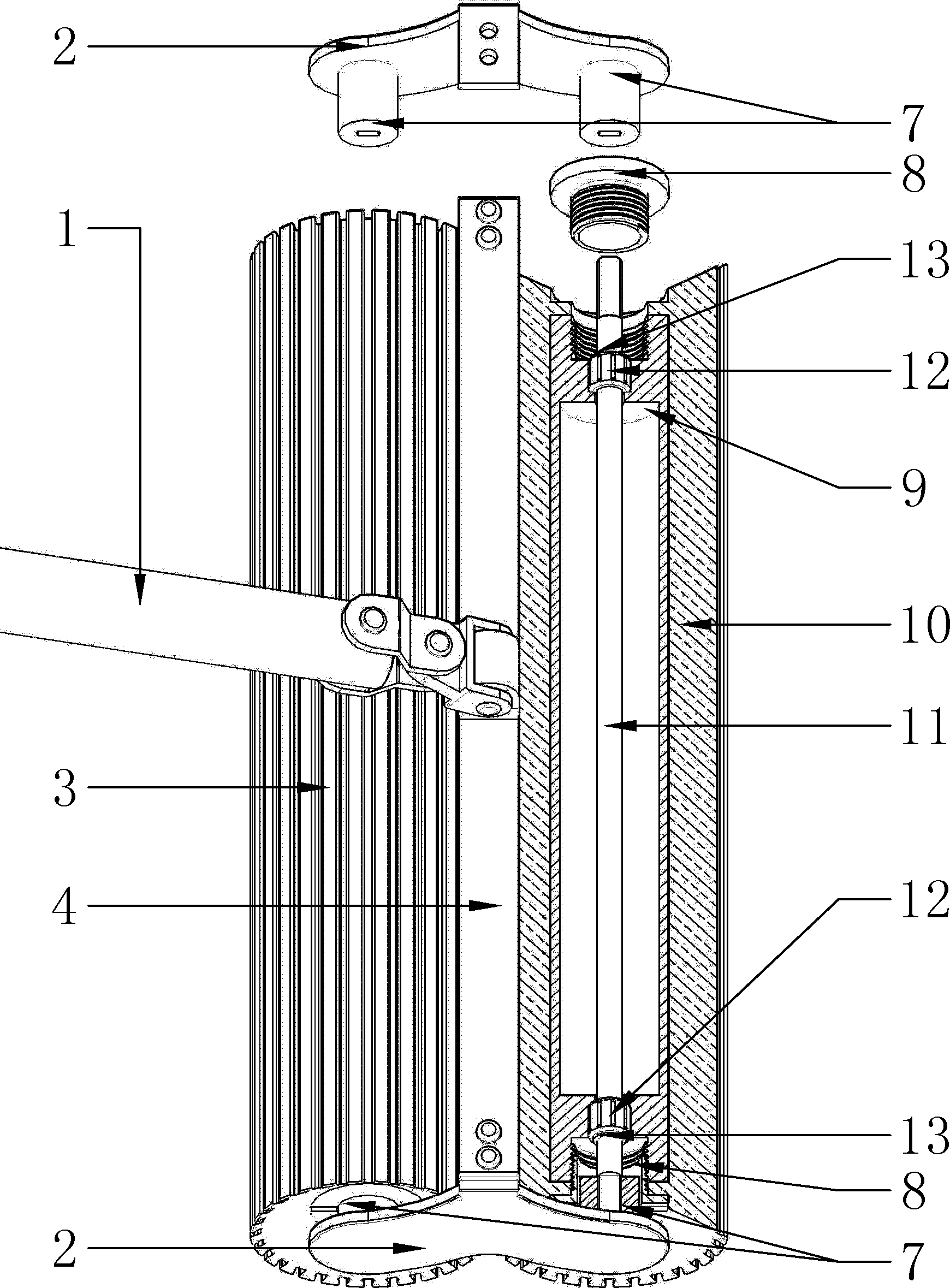

[0023] Embodiment 1: as figure 1 , figure 2 As shown: the lower end of the handle bar 1 is rotationally connected with the beam 4 on the bracket 2, the bracket is a two-piece flat plate structure reinforced by the beam, the beam and the bracket are detachably connected, preferably screwed, and the wiping roller 3 is divided into front and rear Two rows are arranged in parallel, each row has a wiping roller, and the two parallel structures of the bracket are located at the left and right ends of the two rows of wiping rollers.

[0024] The bracket is made of rigid material, and its material can be engineering plastics, metal, bamboo, wood, composite materials, etc., preferably engineering plastics in this embodiment, and a flexible protective cover can also be put on the rigid material, such as putting on A layer of soft glue to prevent scratches on furniture and corners.

[0025] The wiping roller comprises an inner layer support cylinder 9 and an outer layer wiping materia...

Embodiment 2

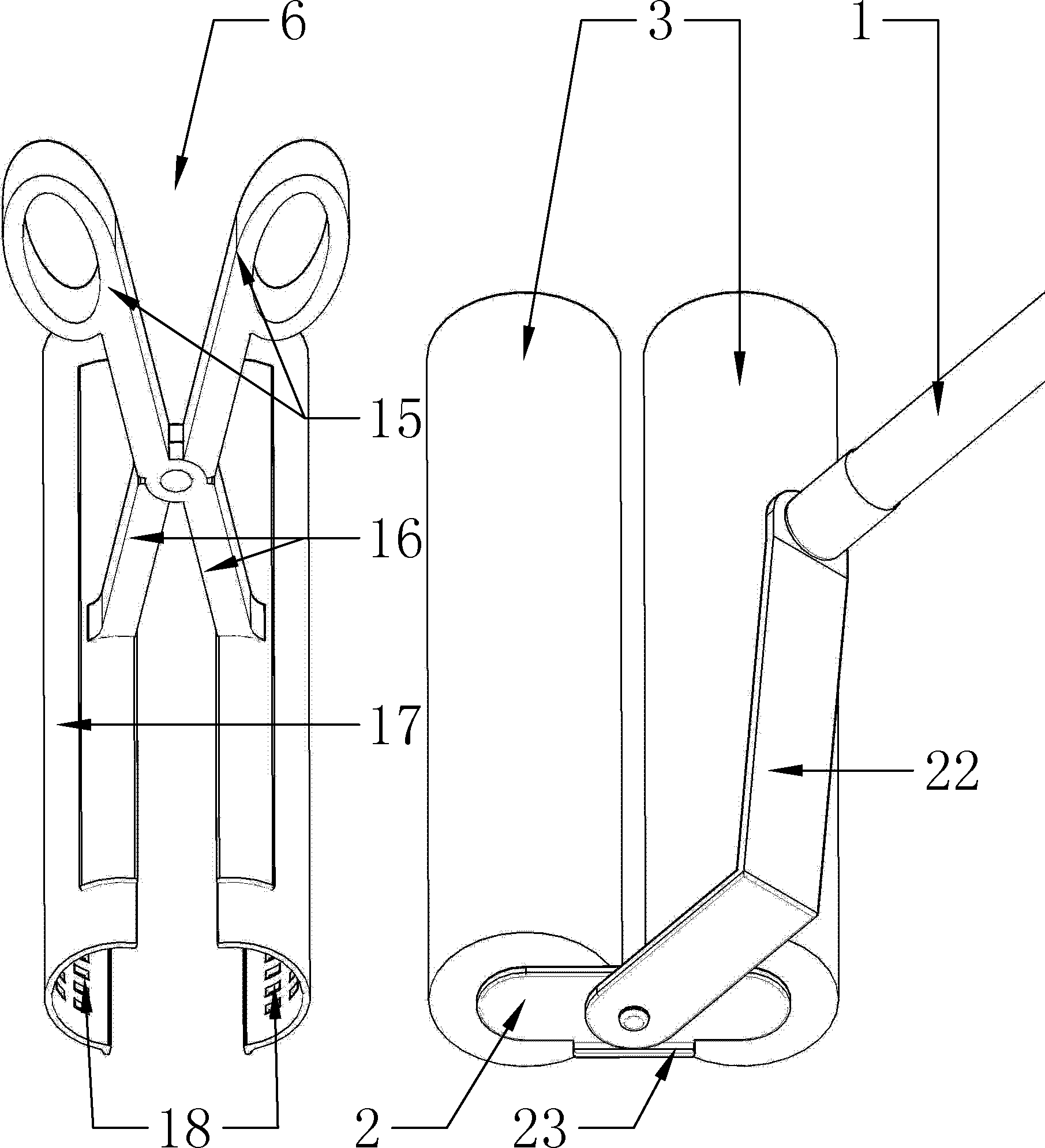

[0032] Embodiment 2: as image 3 , Figure 4 As shown, the handle bar 1 is rotationally connected with the bracket 2 through the L-shaped connecting arm 22 fixed thereon, and the wiping rollers 3 are arranged in parallel in front and rear rows, each row has a wiping roller, and the bracket is a flat plate structure located on the Wipe one end of the roller in two lines. This kind of connection method is adopted between the handle bar and the bracket, which can easily drag and wipe the corners and prevent damage to furniture and walls.

[0033] The wiping cylinder includes an inner support cylinder 9 and an outer layer of wiping material 10 coated on the surface of the inner support cylinder. The inner support cylinder is made of rigid material, preferably engineering plastics in this embodiment; the outer layer of wiping material can be made of flexible The water-absorbing material can also be made of flexible water-absorbing material and then covered with water-absorbing fa...

Embodiment 3

[0039] Embodiment 3: as Figure 5 , Figure 6 As shown, the lower end of the handle bar 1 is rotationally connected with the bracket 2, and the four wiping rollers 3 are arranged in parallel in front and rear rows, each row has two wiping rollers, the bracket 2 is a flat plate structure, and the two wiping rollers located in each row middle. This kind of connection method is adopted between the handle bar and the bracket, which can easily drag and wipe the corners and prevent damage to furniture and walls.

[0040] The wiping roller comprises an inner layer support cylinder 9 and an outer layer wiping material 10 coated on the surface of the inner layer support cylinder. The inner layer support cylinder is made of a rigid material, preferably engineering plastics in this embodiment; the outer layer wiping material is made of flexible water-absorbing The material composition can also be composed of flexible water-absorbing material and then covered with water-absorbing fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com