Manufacturing method for elastic cushion support

A manufacturing method and technology of elastic pads, which can be applied to home appliances, applications, and other seating furniture, etc., can solve the problems of easy moisture, poor elasticity, toughness and air permeability, and easy to be eaten by insects after long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

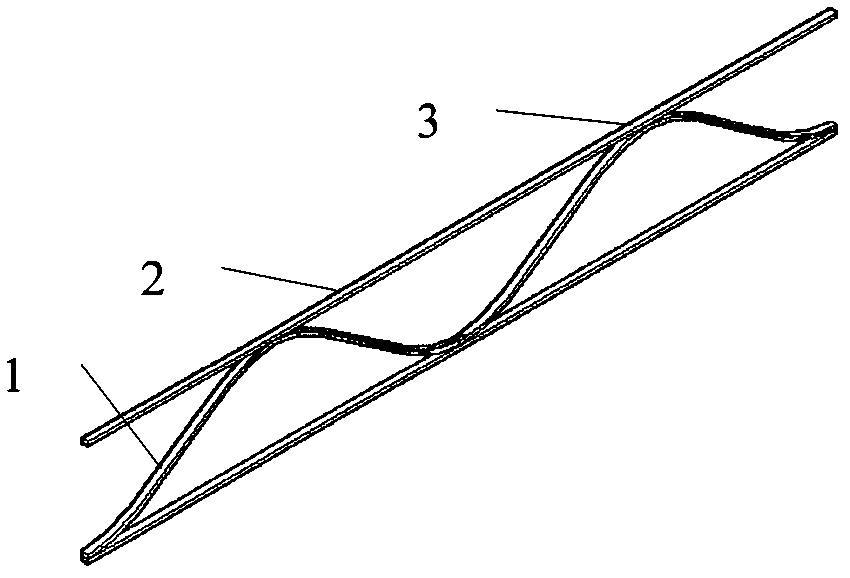

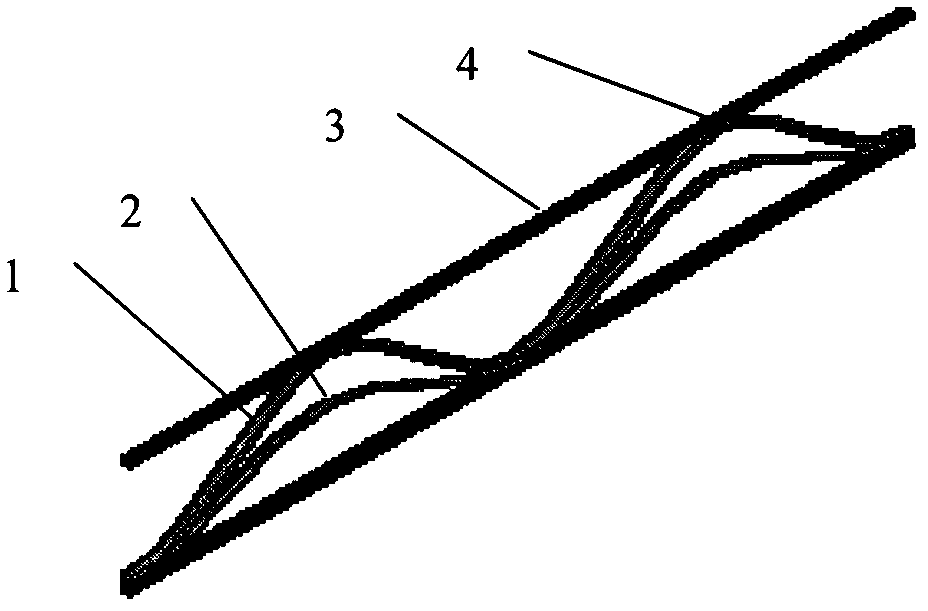

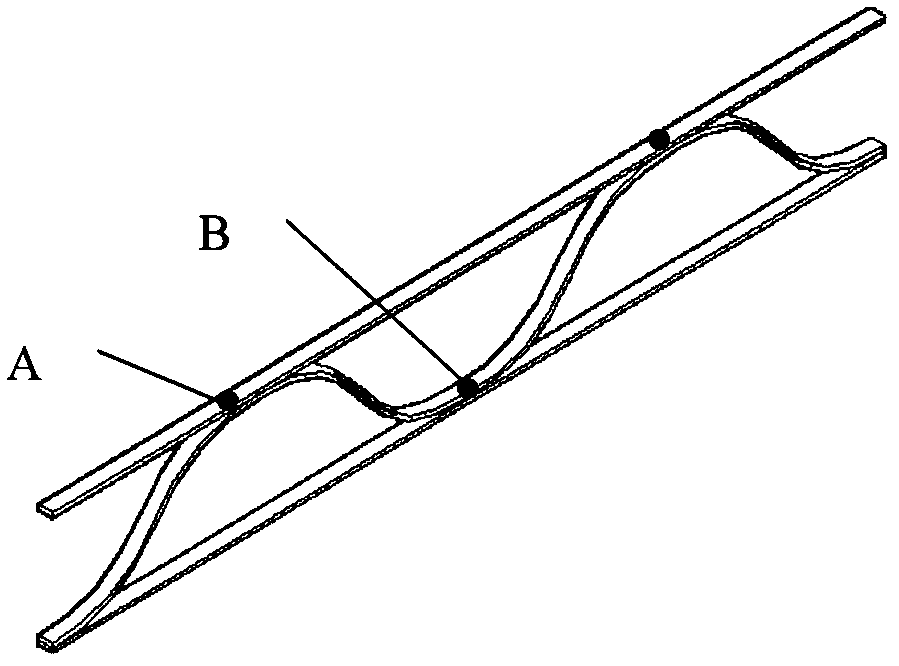

[0040] Refer to attached Figure 4 And attached Image 6 In this embodiment, the basic structural unit of the elastic pad bracket with a uniform structure is a concave-convex elastic support piece and a flexible connecting piece, which are connected by a certain method at the joint point to form a basic unit body. See the attached figure 1 .

[0041] The manufacturing method is as follows: (1) The elastic body is prepared to use an elastic steel sheet with a width of 25mm, a thickness of 1mm, and a certain length, and drill a small hole with a diameter of 4mm at a distance of 150mm; (2) The connecting belt is prepared to use a width of 25mm, a thickness of 2mm, and a length of For a certain canvas braid, drill a small hole with a diameter of 4mm at a distance of 100mm; Lay several connecting strips in the vertical and horizontal direction, and align ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com