Method for adjusting leakage inductance of high-frequency transformer and high-frequency transformer

A high-frequency transformer and high-frequency technology, applied in the electromagnetic field, can solve the problems of increasing the distance, poor magnetic coupling ability, and increasing the volume of the transformer, and achieve the effect of low cost and satisfying requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

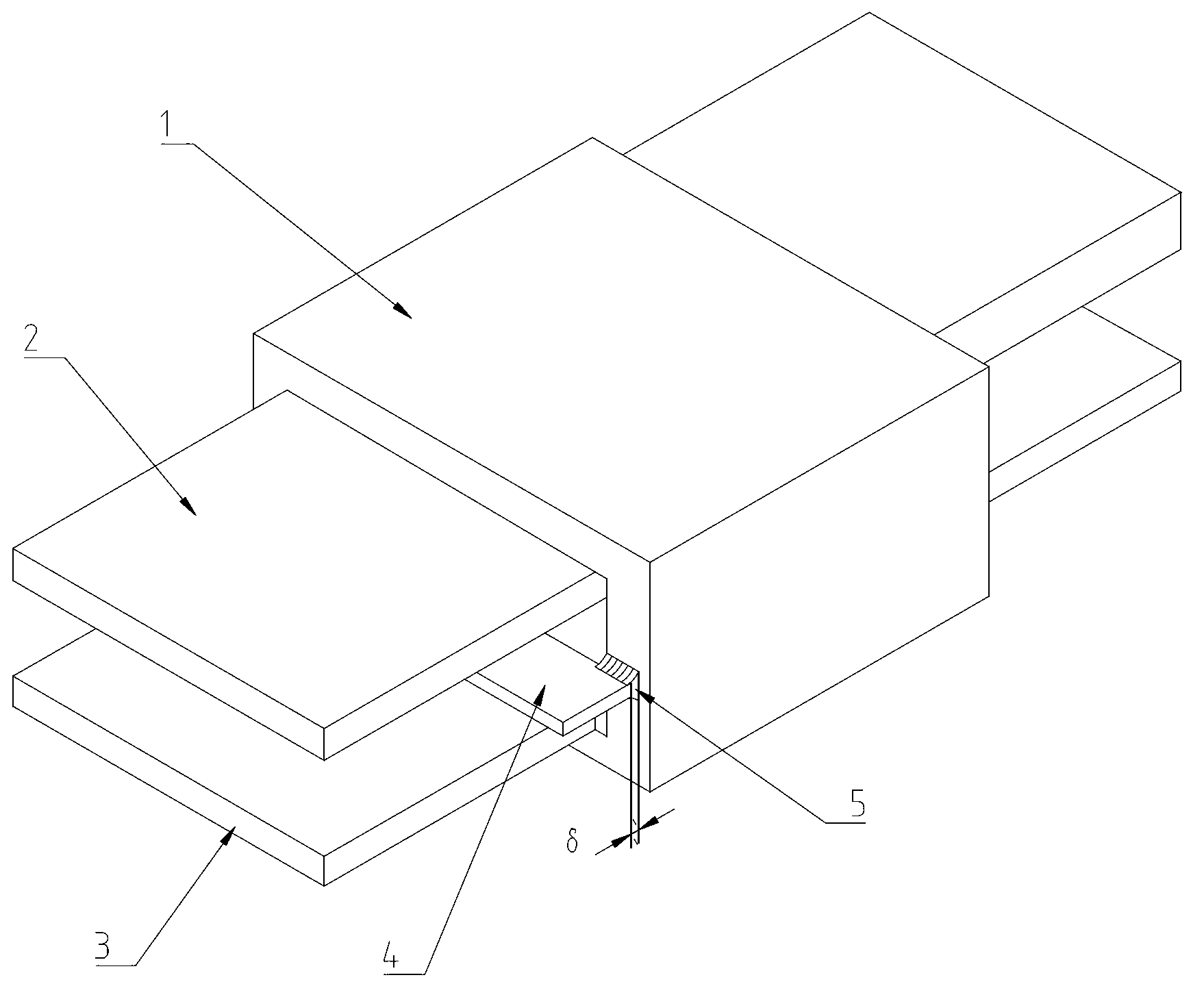

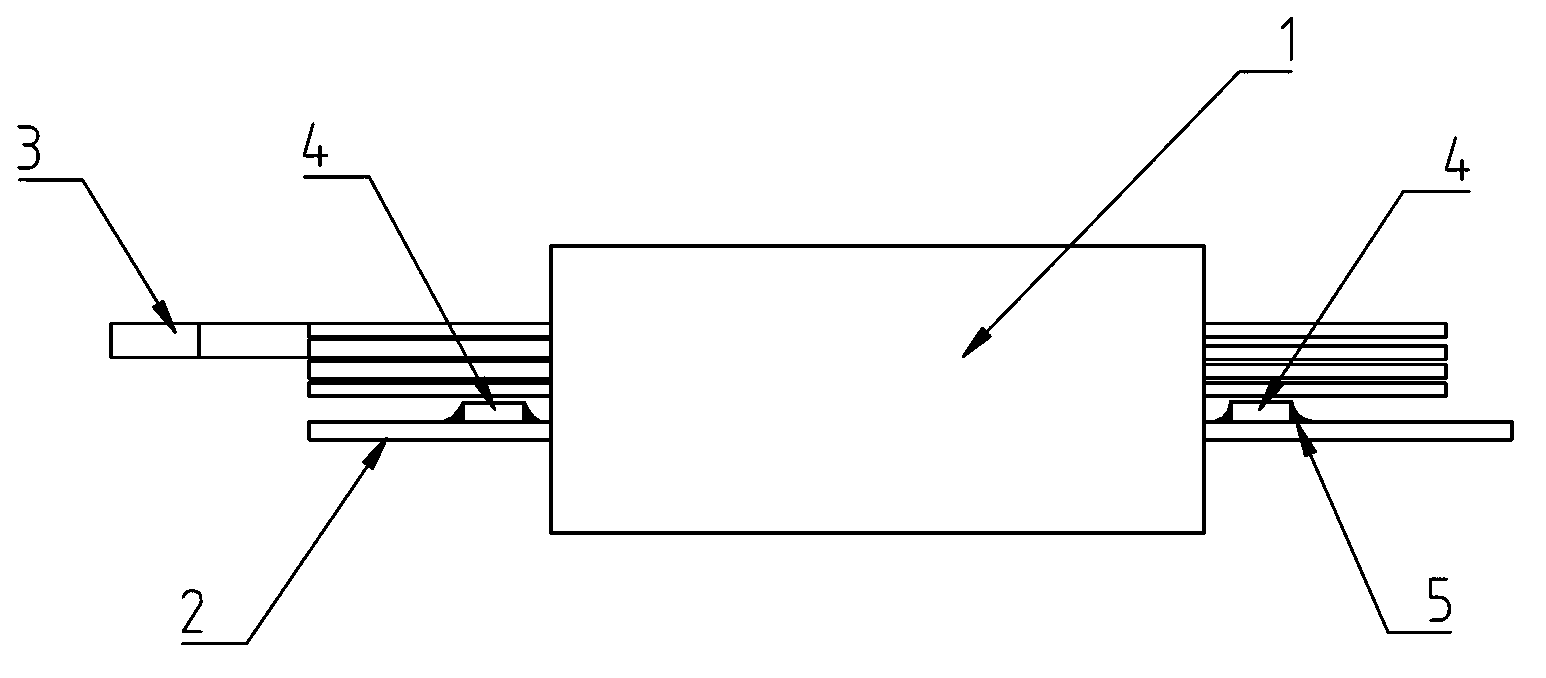

[0027] The high-frequency transformer of embodiment 1 of the present invention such as figure 1 As shown, it includes a magnetic core 1, a primary winding 2, a secondary winding 3 and a high-frequency magnetic strip 4. The high-frequency magnetic strip 4 is arranged between the primary winding 2 and the secondary winding 3, and is located in the high-frequency transformer core 1. The outside of the window is fixed on the magnetic core 1 by an adhesive 5 (such as epoxy resin).

[0028] Magnetic core 1 can be EE, EI, EC, PQ and other power cores; the coil of primary winding 2 can be enameled wire, triple insulated wire, copper foil or PCB; the coil of secondary winding 3 can be enameled wire, triple insulated wire , copper foil or PCB.

[0029] The operating frequency of the high-frequency magnetic strip 4 is as high as 20MHz, and its initial permeability does not decrease at the frequency of 20MHz.

[0030] The material of the high-frequency magnetic strip 4 can be NiZn ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com