Refrigerant-mixing natural gas liquefaction device and technology thereof

A hybrid refrigeration and liquefaction device technology, applied in the direction of refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of multiple equipment, complicated control, long process, etc., and achieve the effect of low operating cost, broad market prospect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

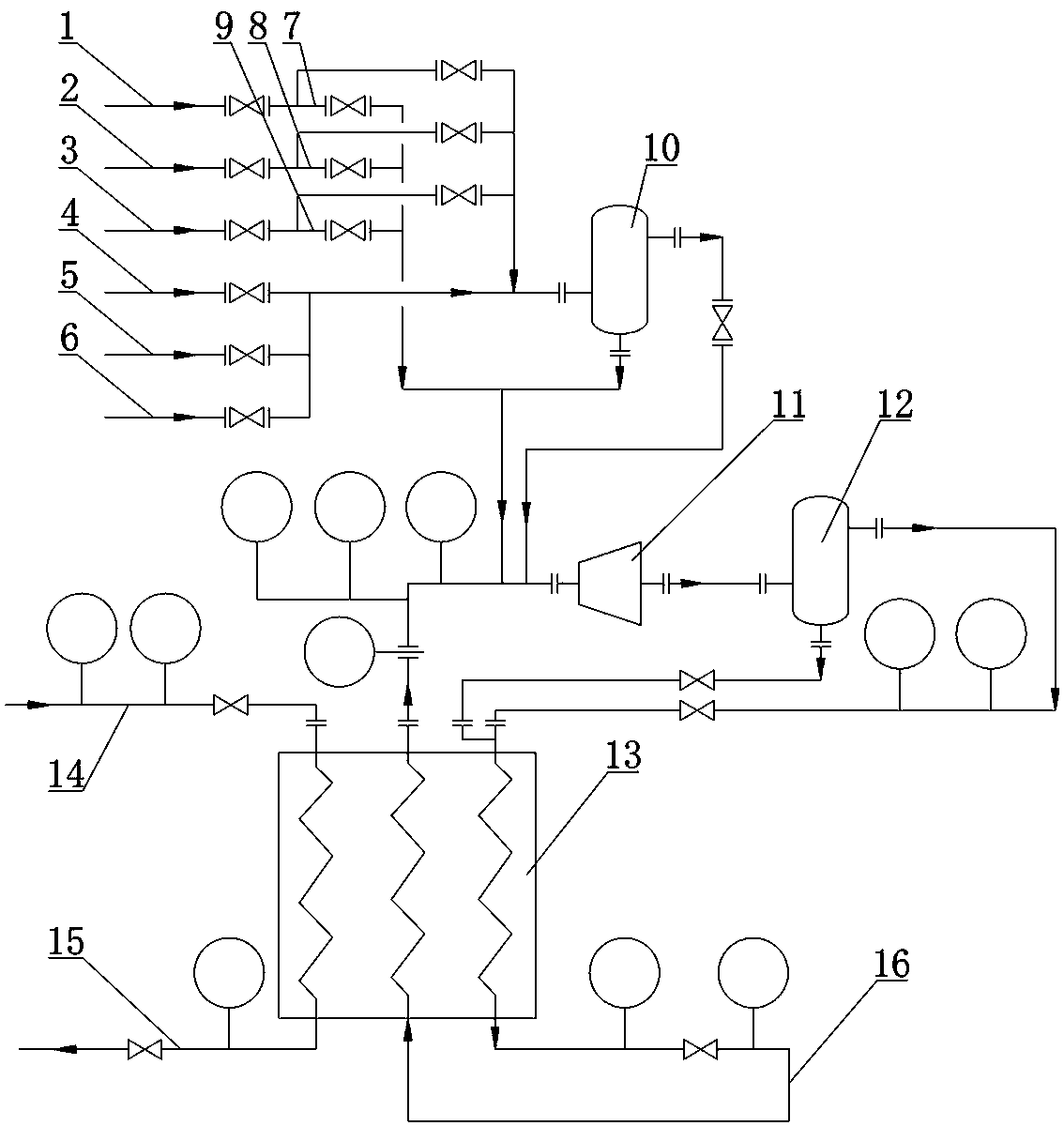

[0021] Such as figure 1 As shown, a natural gas liquefaction device with mixed refrigeration comprises isopentane feed pipe 1, n-butane feed pipe 2, propylene feed pipe 3, ethylene feed pipe 4, methane feed pipe 5, nitrogen feed pipe Material pipe 6, branch pipe A7, branch pipe B8, branch pipe C9, mixed refrigerant proportioning tank 10, compressor 11, separator 12, heat exchanger 13, purified natural gas inlet pipe 14, liquefied natural gas output pipe 15 and connecting pipe 16, Isopentane feed pipe 1, n-butane feed pipe 2, propylene feed pipe 3, ethylene feed pipe 4, methane feed pipe 5 and nitrogen feed pipe 6 are all connected to the inlet of the mixed refrigerant proportioning tank 10. The feed port is connected, the gas discharge port of the mixed refrigerant proportioning tank 10 and the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com