System and method for utilizing flue gas circulation to prevent deflagration of hearth bottom

A flue gas circulation and furnace technology, applied in the combustion method, the safety device of the combustion chamber, the combustion chamber, etc., can solve the problems of easily causing deflagration, accidents, etc., so as to reduce the intensity of deflagration, reduce the possibility and destructiveness, and prevent deflagration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

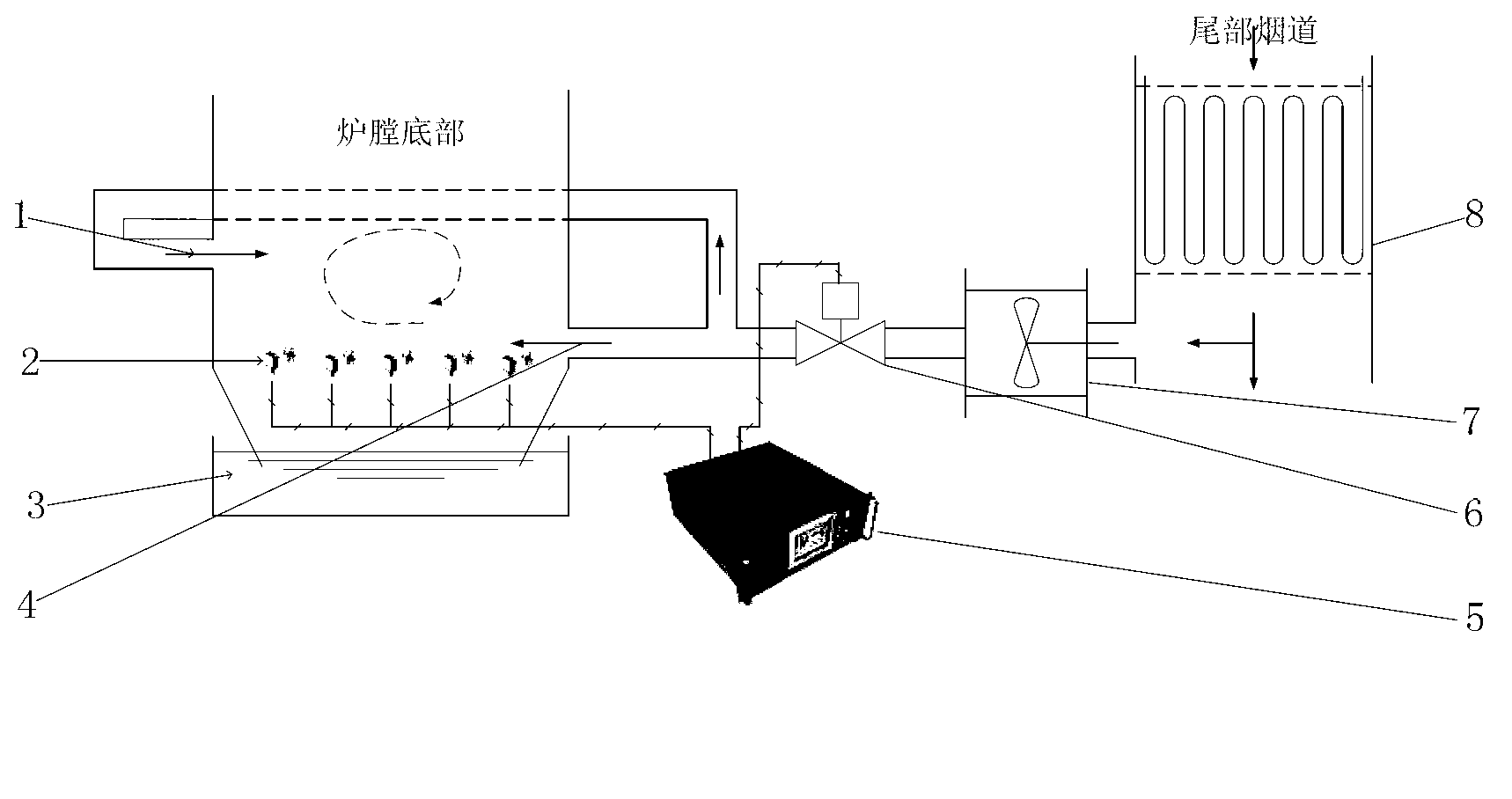

[0024] see figure 1 , the present invention includes several CO concentration on-line monitoring measuring points 2 uniformly arranged along the inner wall circumference of the lower part of the cold ash hopper at the bottom of the furnace, the signal output end of the CO concentration on-line monitoring measuring point 2 is connected with the CO concentration on-line monitoring system arranged outside the furnace 5 is connected to the signal input end, and the output end of the CO concentration online monitoring system 5 is connected to the explosion suppression air regulating valve 6 through the controller, and the inlet of the explosion suppression air regulating valve 6 is connected to the economizer 8 through the axial flow generator 7, The outlet is connected to the explosion-suppressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com