Container lifting mechanism with balance anti-swinging function and eight-rope lifting three-point balancing method using container lifting mechanism

A lifting mechanism and container technology, applied in the direction of transportation and packaging, load block, load hanging components, etc., can solve the problem of uneven force on 8 steel wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

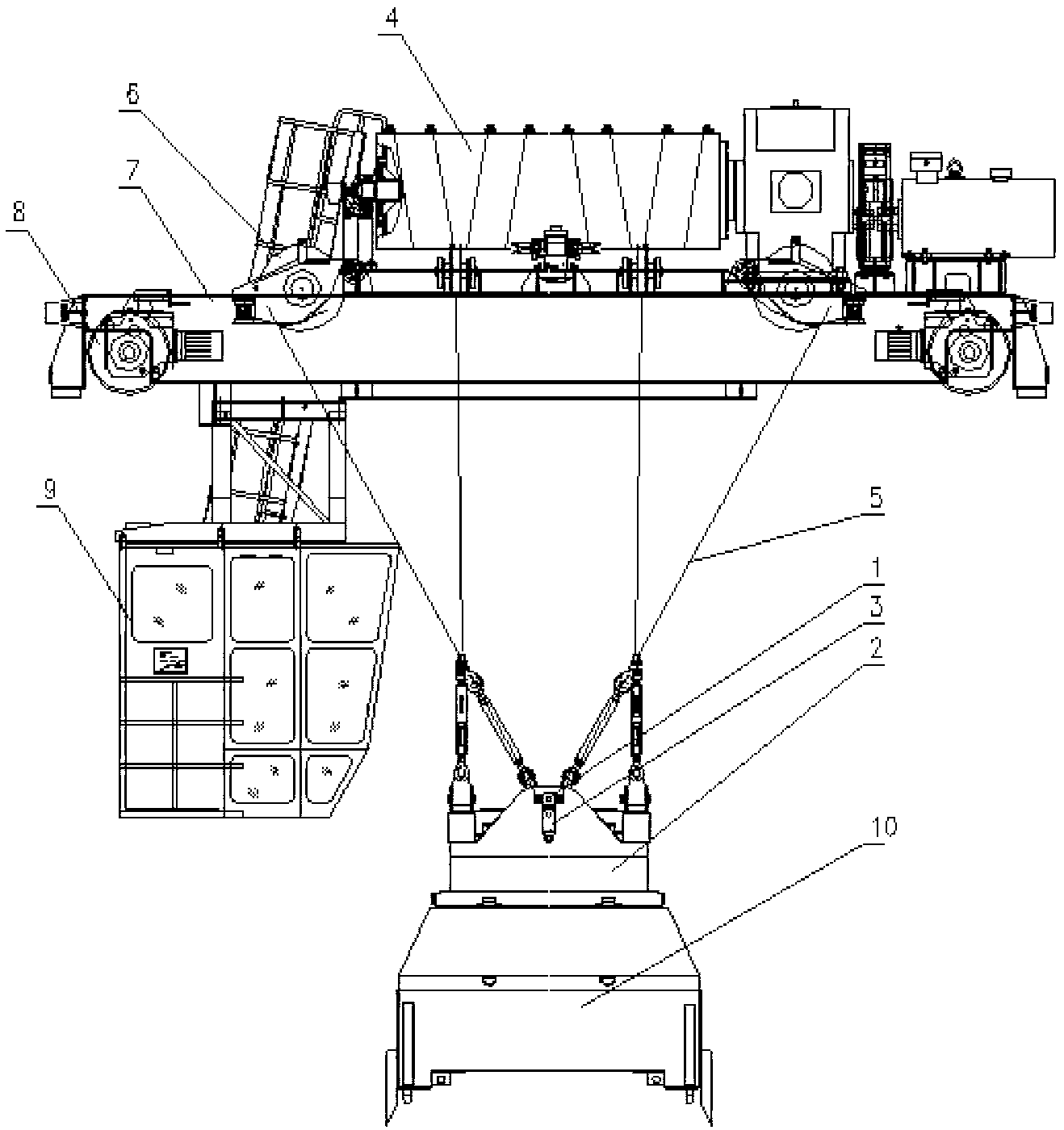

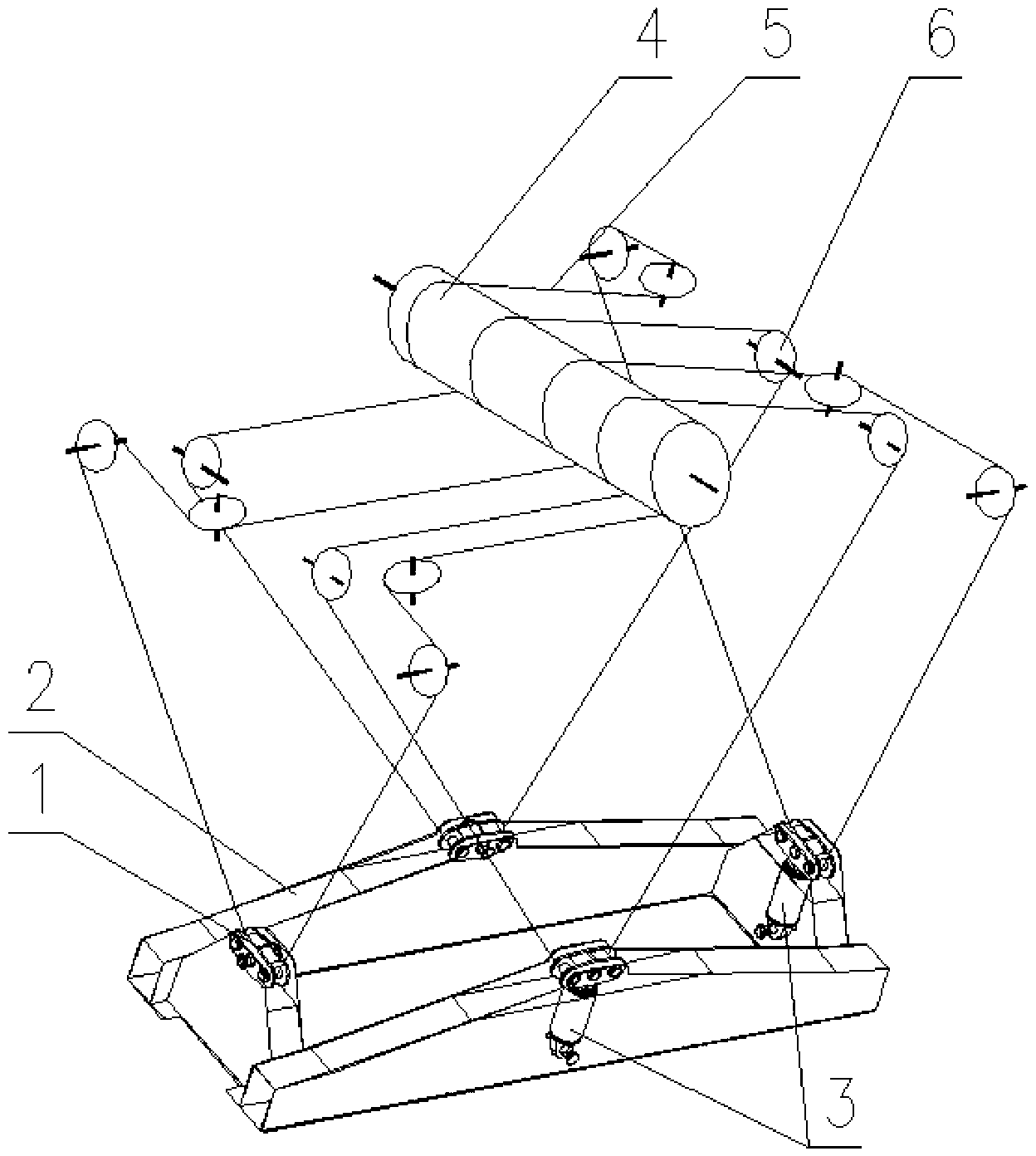

[0025] A container lifting mechanism with balanced anti-sway, including a balanced damping mechanism 1, an upper hanger 2, a balanced oil cylinder 3, a hoist 4, a wire rope 5, a redirecting pulley 6, a lifting trolley 7, and a trolley wheel 8, Control room 9 and container spreader 10.

[0026] Wherein, the number of the equalizing damping mechanism 1 is four, and the four equalizing damping mechanisms are installed on the four sides of the upper hanger 2, the number of the equalizing oil cylinder 3 is two, and the upper cavity is connected by a connecting pipe. .

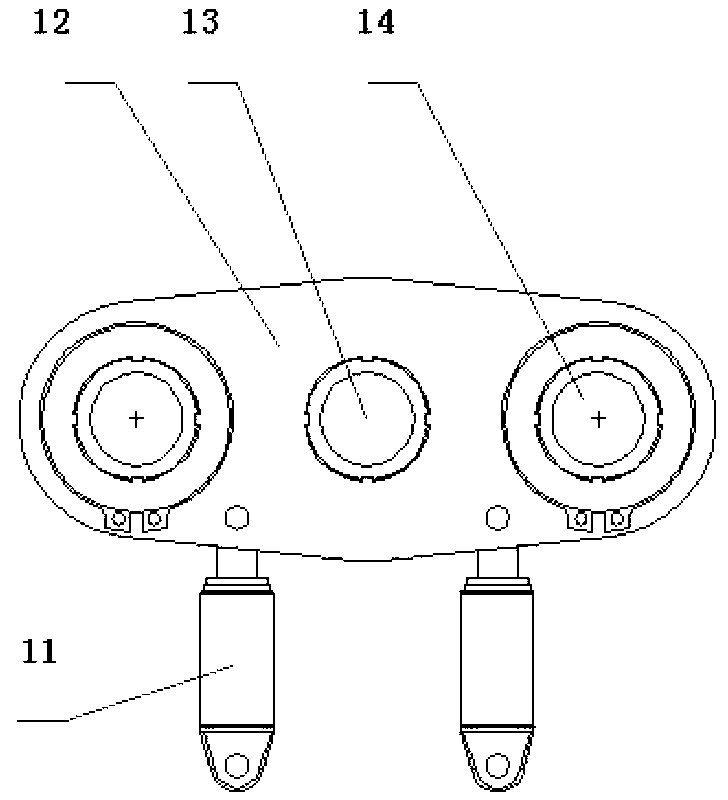

[0027] Wherein, the equalizing damping mechanism 1 includes a damping cylinder 11, an equalizing frame 12, a center pin 13 and a rope end fixing pin 14.

[0028] Wherein, the lower part of the damping cylinder 11 is pin-connected to the upper hanger 2, and the upper part of the damping cylinder 11 is pin-connected to the equalizing frame 12. The damping cylinder 11 has a damping function, and the equalizing frame 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com