Special lifting appliance for H-shaped steel beam and lifting method using lifting appliance

A hoisting method, H-shaped steel technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of long hoisting time, slow installation progress, damage to steel beam paint and steel wire rope, etc., to reduce installation and disassembly time , easy installation and disassembly, and the effect of speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

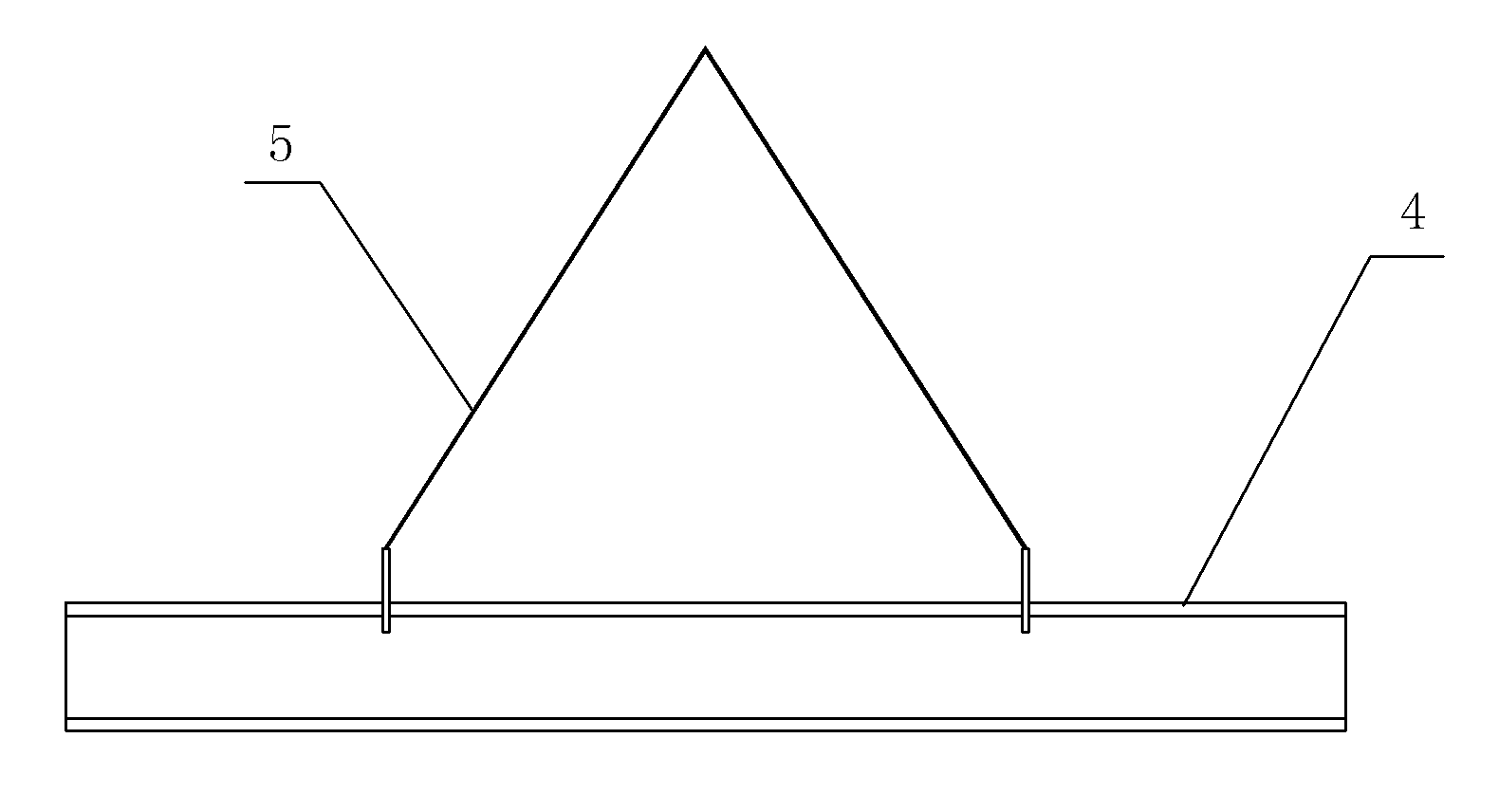

[0018] Such as figure 1 As shown, one of the present embodiments includes a spreader body in the shape of an open groove, one end of the spreader body is provided with a threaded section 1 of M20, the other end is provided with a lifting hole 2, the threaded section 1 of the spreader body and the lifting Between the holes 2 is a tank body 3 for accommodating part of the flange plates of the H-shaped steel beam 4 .

[0019] Such as figure 2 and image 3 As shown, the hoisting method utilizing the above-mentioned H-shaped steel beam 4 special spreaders comprises the following steps:

[0020] a. Open a mounting hole with a diameter of 25mm on the flange of the H-shaped steel beam 4. The mounting hole is symmetrical along the length and width of the upper wing of the H-shaped steel beam 4, and the center line of the mounting hole reaches the flange of the H-shaped steel beam 4. The distance outside the plate is equal to the distance from the center line of threaded section 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com