Sliding guide shoe and elevator provided with sliding guide shoe

A technology of elevators and elevator cars, which is applied in the direction of transportation and packaging, elevators, etc., can solve the problems of improving sliding guide shoes, disturbing passengers, inaccuracy, etc., achieves reduced vibration and noise, easy manufacturing, and good manufacturing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

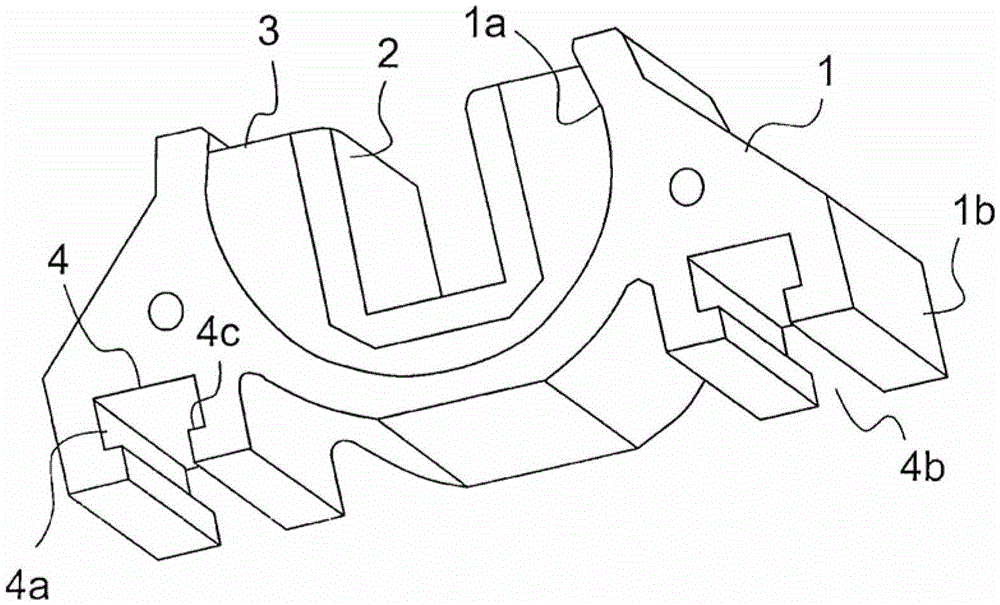

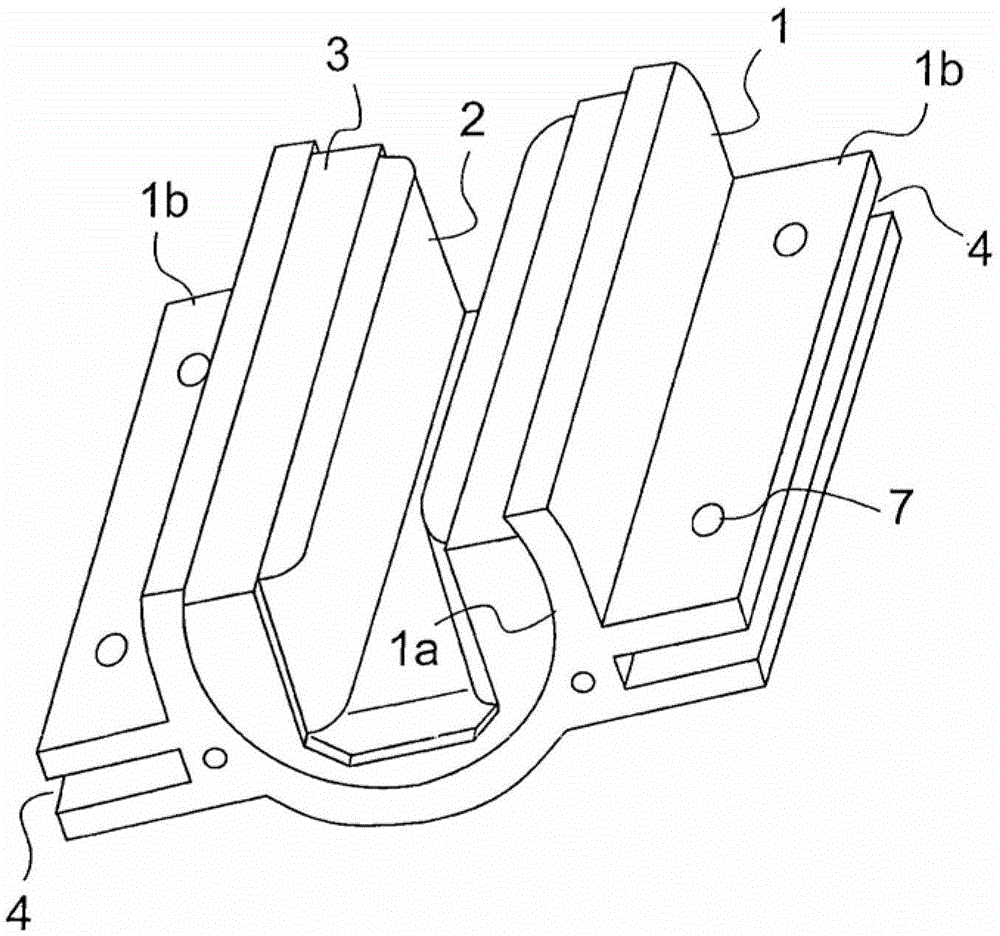

[0028] figure 1 A sliding guide shoe according to the invention is shown, comprising: a main body part 1 comprising a trough-shaped sliding pad space 1a, the cross-section of which is curved and directed towards the front, ie towards the elevator The guide rails of the car, the opening; and the two fixed parts 1b on the sides. The sliding pad 2 that actually damps vibrations and vibrations is fixed to the pad space 1a via a groove-shaped spacer 3 opening forward, such as an elastic body, which is supported on the curved surface of the pad space 1a. The sliding pad 2 is for example glued to the spacer part 3 .

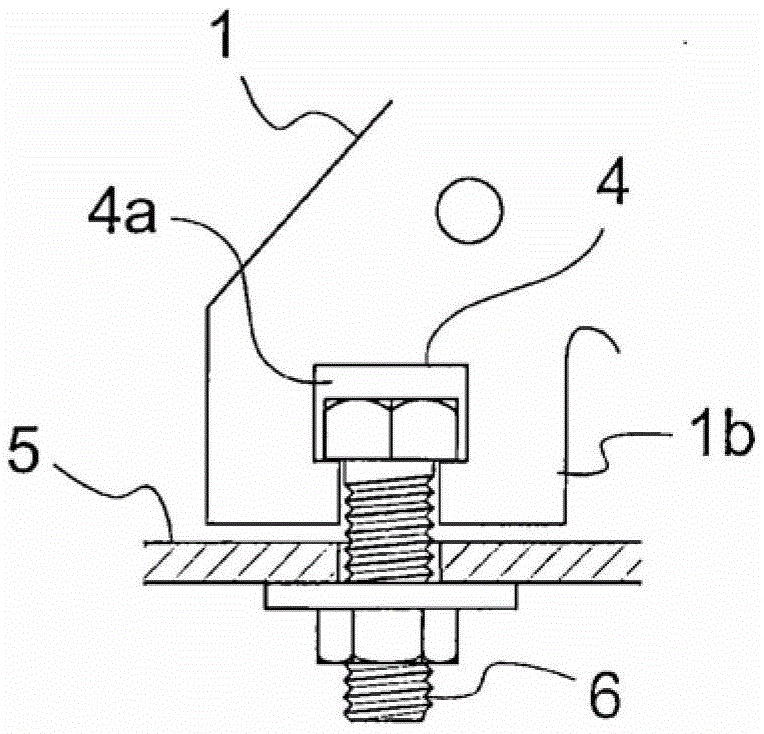

[0029] The fixing part 1b of the body part has substantially the entire length of the body part 1 and the fixing part 1b comprises a profile groove 4 having the length of the body part 1 and opening towards the rear for fixing said sliding guide shoe. The cross-section of this type groove 4 is for example a typical T-shaped groove, which comprises a wider part 4a for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com