Method for detecting defects of printed circuit board (PCB) based on skeleton extraction and range conversion

A printed circuit board, distance conversion technology, applied in measuring devices, character and pattern recognition, instruments, etc., can solve problems such as non-detection, false alarms, loss, etc., to reduce calculation deviation, reduce calculation amount, and improve defect identification. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

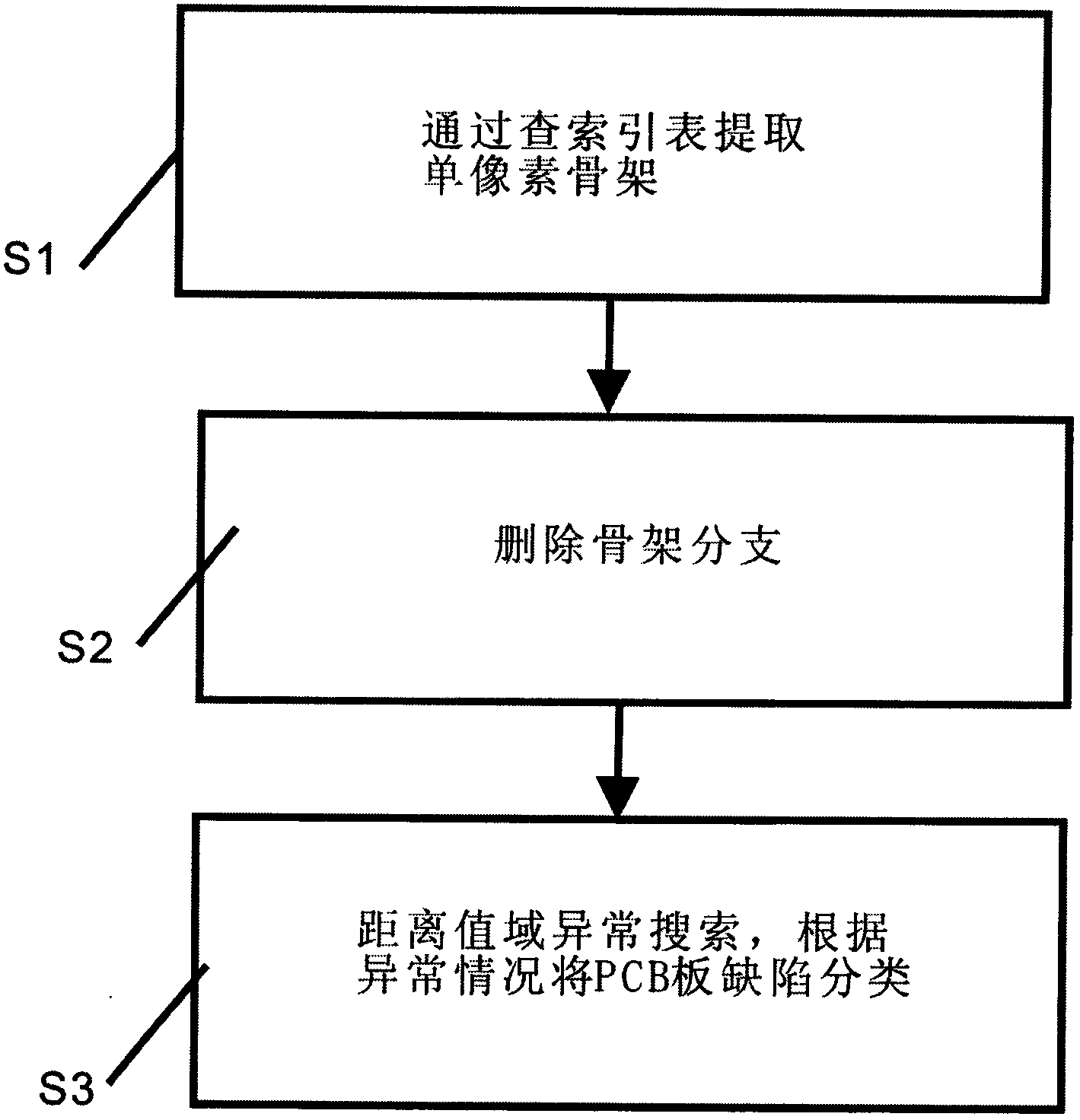

[0029] See figure 1 , The method for detecting defects of printed circuit boards based on skeleton extraction and distance transformation provided by the present invention includes the following steps:

[0030] S1. Extract a single pixel skeleton by looking up the index table;

[0031] S2, delete the skeleton branch;

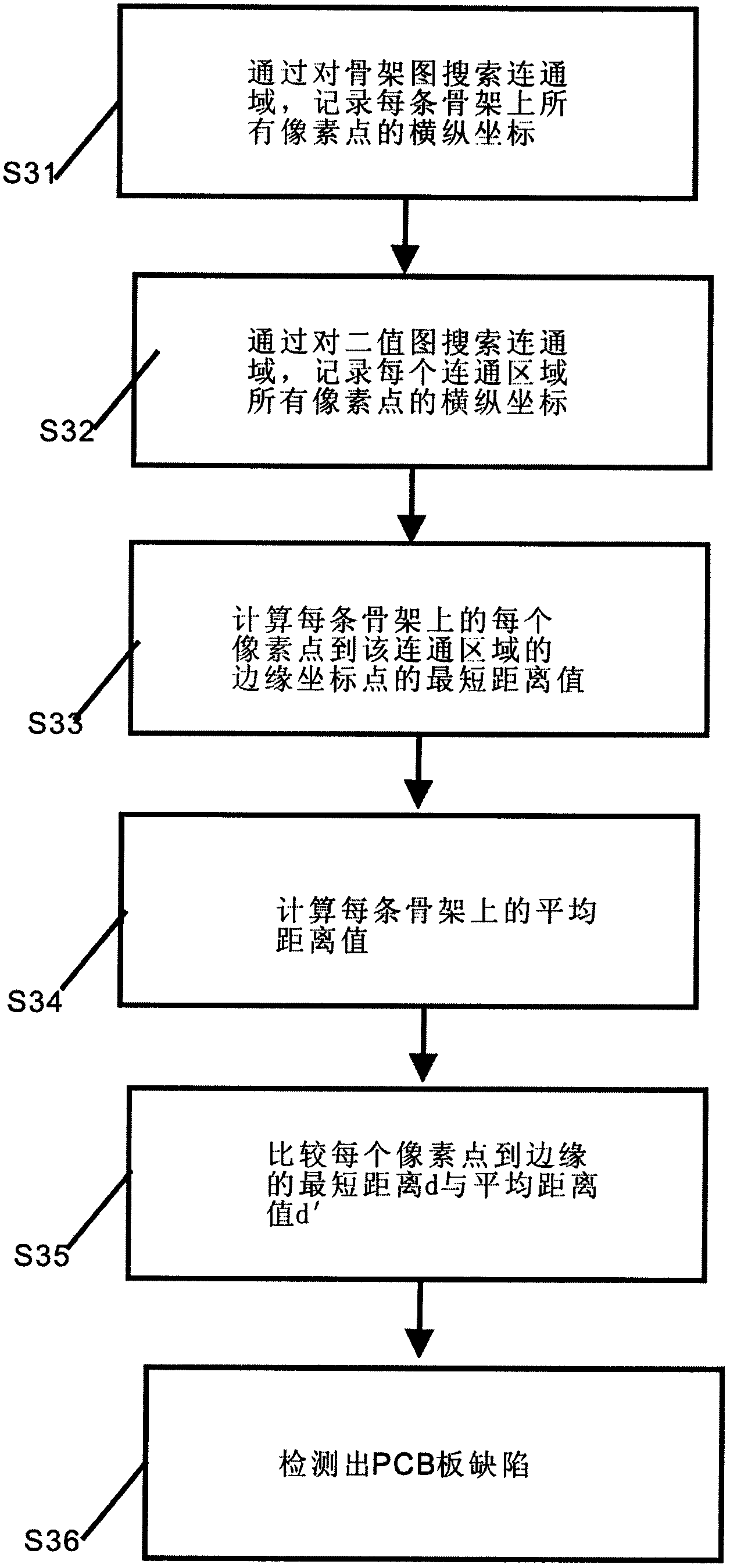

[0032] S3. Search for abnormal distance range, and classify PCB board defects according to abnormal conditions.

[0033] See Figure 3-Figure 5 , In step S1, including by judging the eight connected domains around the pixel, under the premise of ensuring that the number of connected domains is not affected, the useless points are deleted in the index table method. In the index table method, internal points, breakpoints, Isolated points and boundary points cannot be deleted. The method of using the index table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com