Novel axle head nut

A new type of nut technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problem that the axle head nut and nut cannot realize the pretightening force, cannot effectively protect the bearing and the axle, and the axle head nut has poor locking effect To achieve the effect of enhancing brand effect, ensuring mechanical strength and rigidity, and optimizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

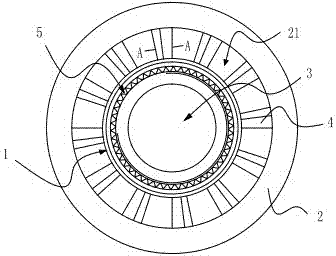

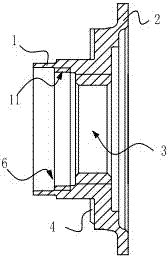

[0020] Such as figure 1 , 2 , 3, 4, and 5, a new type of shaft nut, including a threaded body 1 that is threaded with the axle, and a locking flange 2 integrally formed with the threaded body 1, between the threaded body 1 and the An inner cavity 3 that can accommodate the axle is formed between the locking flanges 2. The inner cavity 3 is arranged through the axis of the axle head nut, and is on the back 21 of the locking flange 2, around the locking flange 2. A key 4 connected to the hub of the axle is provided in the circumferential direction of the axis of the threaded body 1. In the inner cavity 3 of the threaded body 1, around the axis of the threaded body 1, a plurality of threads along the inner wall 11 of the threaded body 1 are provided in the circumferential direction. Splines 5 arranged in the axial direction of the connecting body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com