Angle driver and steering control mechanism

An angular transmission and meshing mechanism technology, applied in mechanical steering gears and other directions, can solve the problems of excessive steering four-bar linkage, abnormal tire wear, increased clearance and other problems, so as to overcome the difficulty of layout and the adjustment of assembly and coordination. Convenience and stiffness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

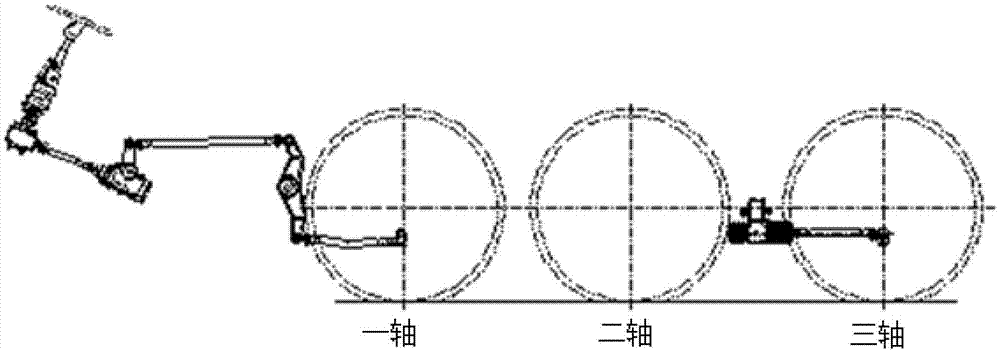

[0042] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0043] Figure 7 It is a schematic front view of an embodiment of the angular transmission provided by the present invention, Figure 4 for Figure 8 sectional schematic diagram. Such as Figure 7 , Figure 8 As shown, compared with the angle transmission in the prior art, the angle transmission 1 provided by the present invention includes an input shaft 2 , a first output shaft 3 , an engagement mechanism, a first housing 4 and a second housing 5 . Wherein: the axis of the input shaft 2 is perpendicular to the axis of the first output shaft 3 , and the input shaft 2 is rotationally connected with the first output shaft 3 through the engaging mechanism.

[0044] However, in view of the fact that the first output shaft 3 can only be connected to a steering gear, the angle transmission 1 provided by the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com