Cross head for cross head diesel engine

A crosshead type, diesel engine technology, applied in the crosshead field, can solve problems such as surface pressure rise, cost increase, lubricating oil film rupture, etc., and achieve the effect of reducing thickening and lightening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

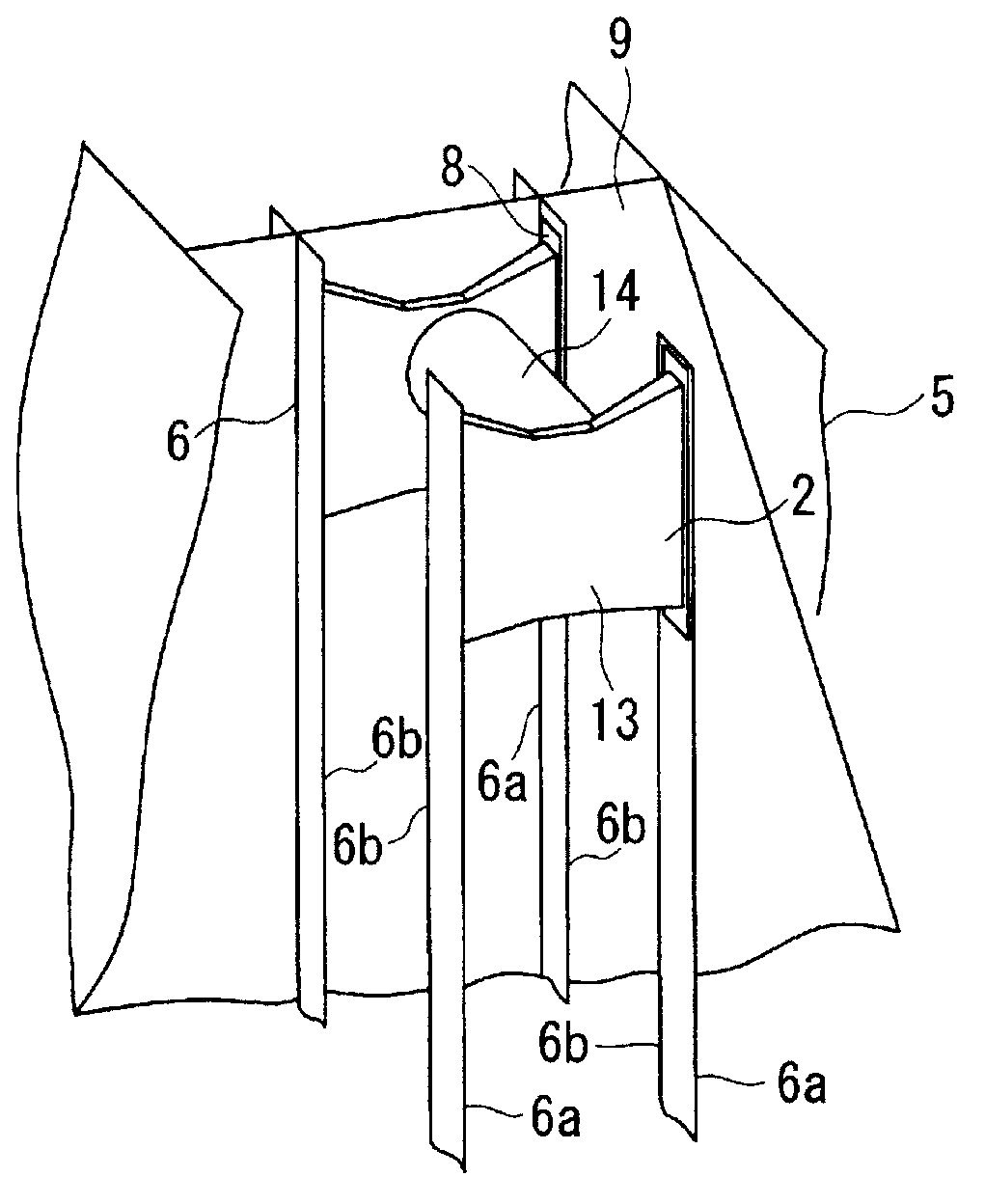

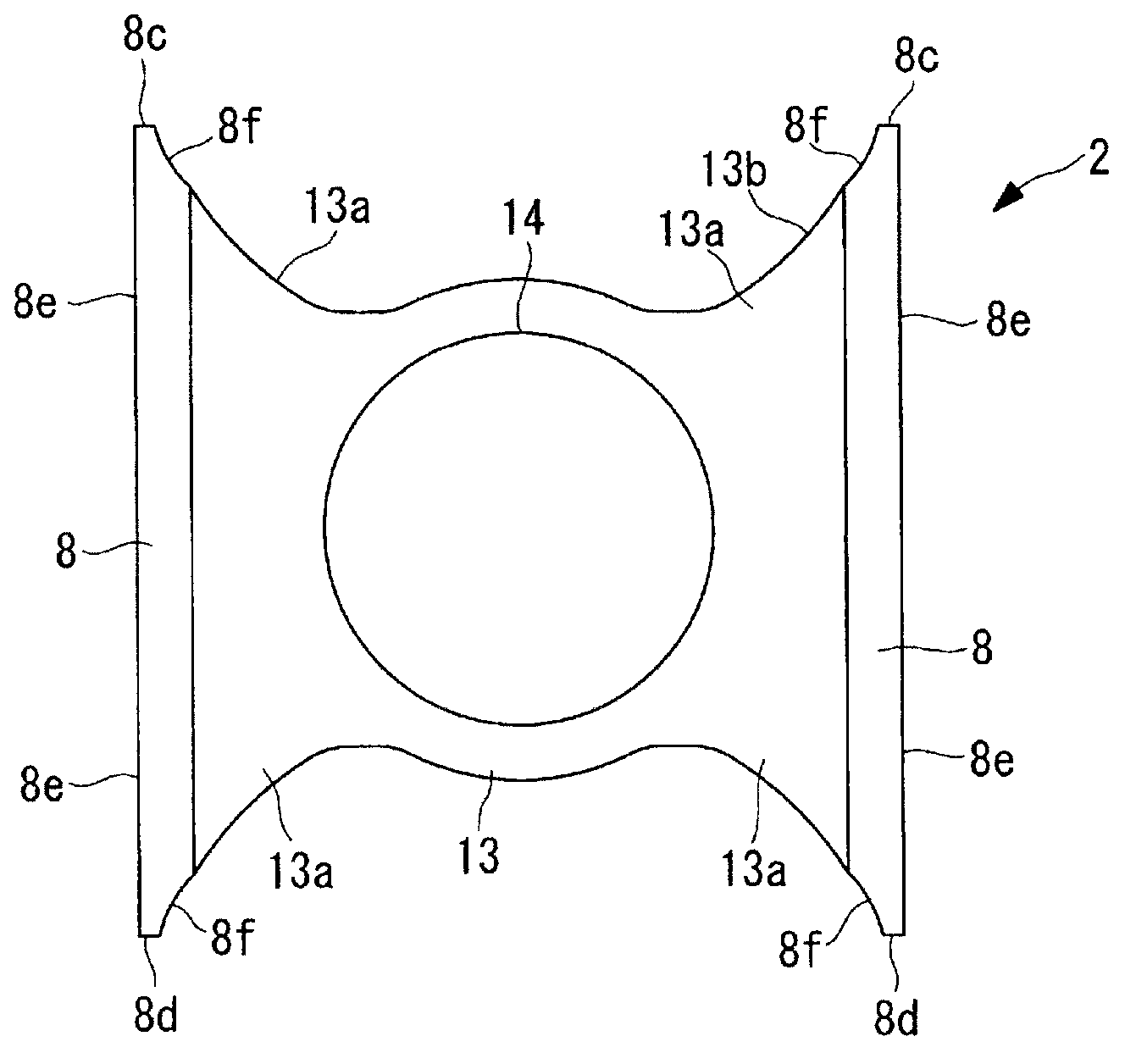

[0055] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

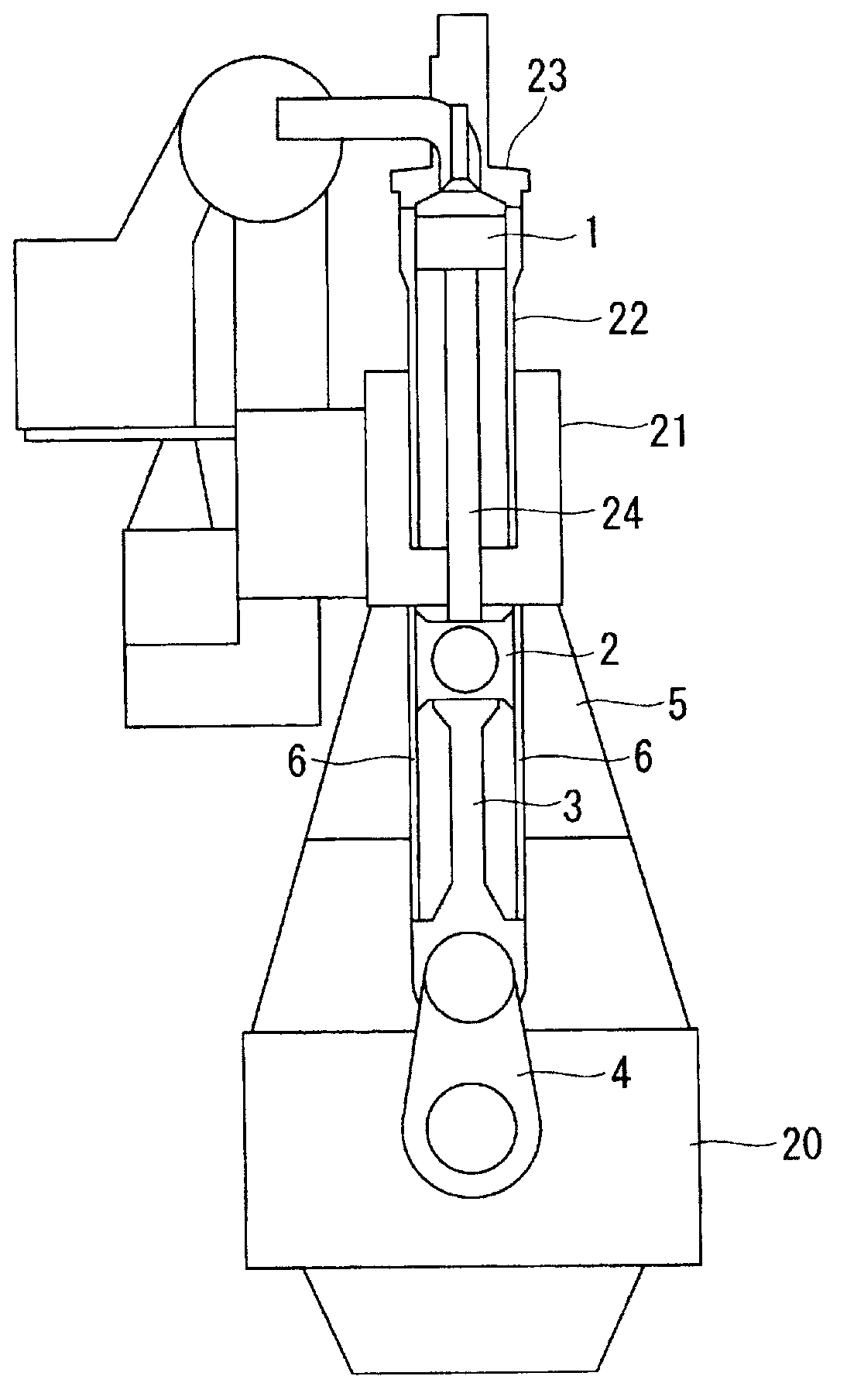

[0056] figure 1 A schematic configuration of a crosshead diesel engine according to an embodiment of the present invention is shown. The diesel engine shown in this figure is mainly used as the main engine for ship propulsion, and it is a two-stroke one-working cycle DC scavenging method.

[0057] This diesel engine has: a frame 20 located below; a frame (main body) 5 provided on the frame 20 ; and a cylinder block 21 provided on the frame 5 . The machine base 20, the machine frame 5, and the cylinder body 21 are fastened and fixed integrally by a plurality of tension bolts (not shown) extending in the vertical direction.

[0058]A cylinder liner 22 is provided on the cylinder block 21 , and a cylinder head 23 is provided at the upper end of the cylinder liner 22 . A reciprocating piston 1 is provided in a space formed by the cylinder liner 22 and the cylinder head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com