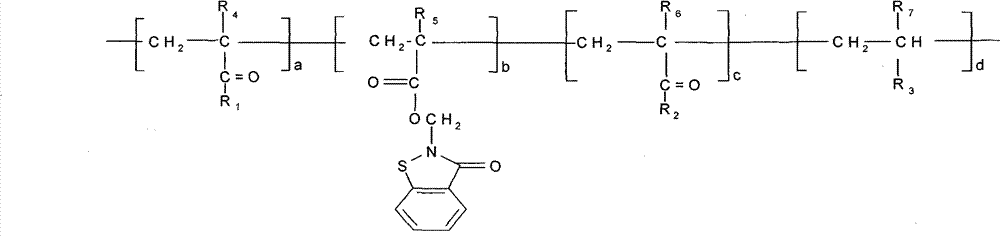

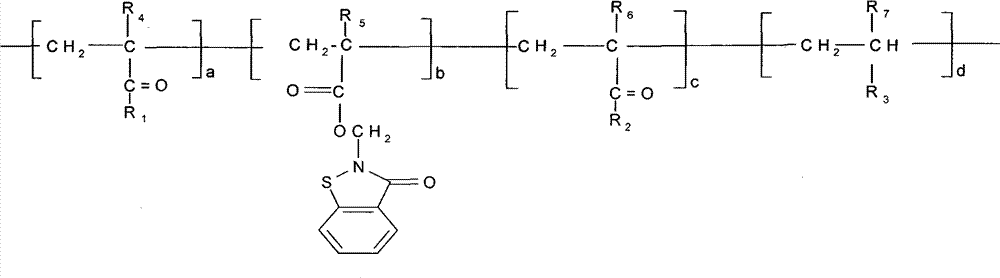

Polyacrylate antifouling copolymerization resin with side chain comprising benzisothiazolinone and preparation method thereof

An antifouling copolymer resin, benzisothiazolinone technology, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem of short antifouling period and difficult antifouling coatings. Problems such as uniform and controlled release of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] In a 500ml four-necked flask equipped with a reflux condenser and a thermometer, add 150g N, N-dimethylformamide, add 15g N-acryloxymethylbenzisothiazolinone, 65g methyl methacrylate, 20g Butyl acrylate, 1g of azobisisobutyronitrile, heated up to 80°C while stirring with nitrogen gas, kept the temperature at 82±2°C for 5 hours, and cooled down to obtain light yellow, clear and transparent side chain containing benzisothiazolinone Polyacrylate antifouling copolymer resin1.

Embodiment 2

[0012] In a 500ml four-necked flask equipped with a reflux condenser and a thermometer, add 150g N,N-dimethylformamide, add 15g N-methacryloyloxymethyl benzisothiazolinone, 61g methyl methacrylate Esters, 24g of butyl acrylate, 1g of azobisisobutyronitrile, heated up to 80°C while stirring with nitrogen gas, kept the temperature at 82±2°C for 5 hours, and cooled down to obtain a light yellow, clear and transparent side chain containing benzo Isothiazolinone polyacrylate antifouling copolymer resin 2.

Embodiment 3

[0014] In a 500ml four-neck flask equipped with a reflux condenser and a thermometer, add 150g N,N-dimethylformamide, add 15g N-methacryloyloxymethyl benzisothiazolinone, 55g methyl methacrylate Ester, 20g butyl acrylate, 10g vinyl acetate, 1.5g azobisisobutyronitrile, stir and heat up to 80°C while blowing nitrogen gas, keep the reaction at 82±2°C for 5 hours, cool down, and obtain a light yellow, clear and transparent side Chain-containing benzisothiazolinone polyacrylate antifouling copolymer resin 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com