Multi-cavity oil tank

A multi-chamber and fuel tank technology, applied in the field of fuel tanks with a multi-chamber structure, can solve the problems of economic loss, oil theft, and no anti-theft measures in the fuel tank, and achieve the goals of reducing economic losses, good anti-theft structure, and increasing theft time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

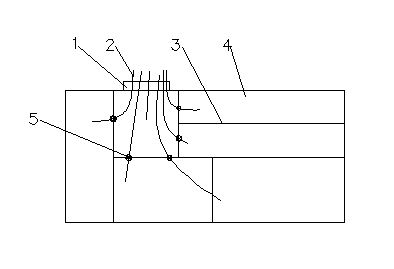

[0011] The present invention isolates the oil tank into a plurality of independent chambers 4 by a plurality of partitions 3, wherein a certain chamber 4 is provided with an oil port 1, and the oil port 1 of the present invention is provided with several oil pipes extending to each chamber 4 2. The joints between the oil pipes 2 and the chambers 4 they pass through are sealed with gaskets 5 .

[0012] When the present invention is in use, first store the corresponding oil in the corresponding chamber 4 through each oil pipe 2 and the marks on it, and when in use, take out the required oil from the corresponding chamber 4 through the oil pump. To improve the sealing performance between the chambers 4 , a gasket 5 is provided at the connection between the oil pipe 2 and the corresponding chamber 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com