Queen bee steel wire cage

A steel wire and honeybee technology, applied in beehives, beekeeping, applications, etc., can solve the problems of easy deformation, undurable production, and troubles of bee king cages, and achieve the effects of long service life, less consumables, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

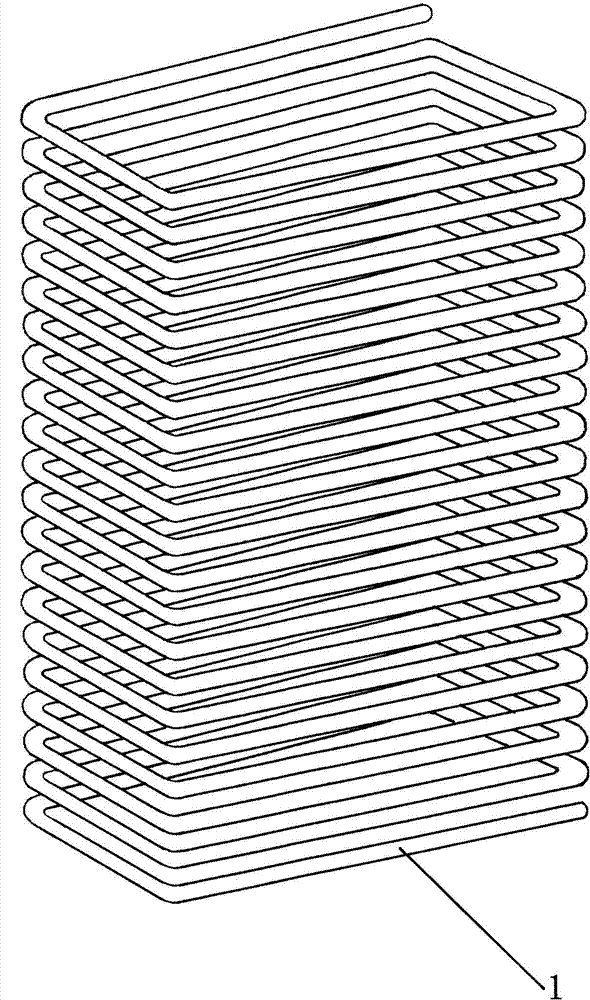

[0011] In Figure 1, a stainless steel wire or electro-galvanized iron wire with a diameter of 0.8 to 1.5 mm is used. A rectangular steel rod with a width of 25-50 mm and a thickness of 10-15 mm, or a rectangular hard wooden rod, is wrapped around 20-40 times and stretched to 40-80 mm to make a steel wire cage (1) .

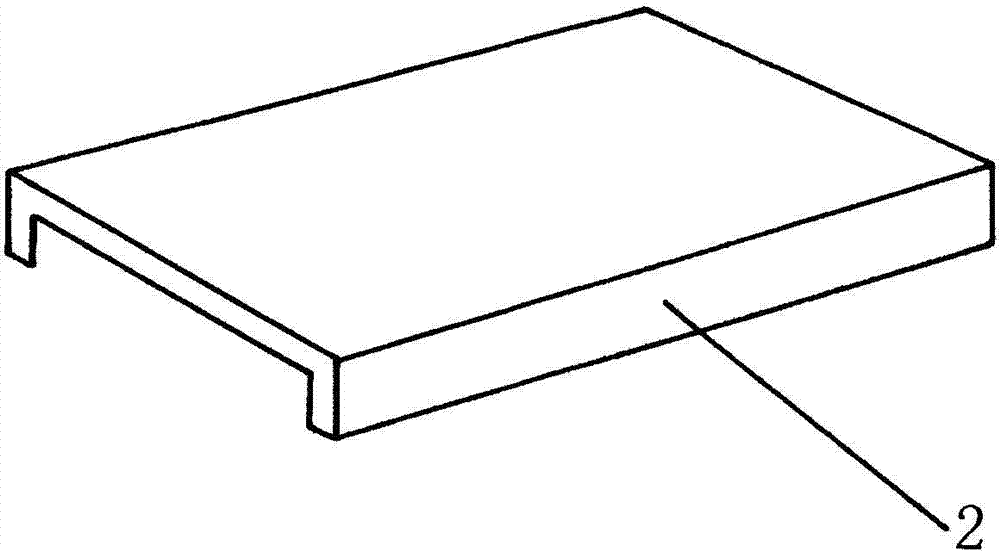

[0012] Figure 2 Use a metal sheet with a thickness of 0.2 to 1.2 mm or use an ordinary metal packaging box to cut into two rectangular metal sheets with a length of 25 to 50 mm and a width of 12 to 25 mm. Bend 1-5 mm to form two concave metal end cover plates (2).

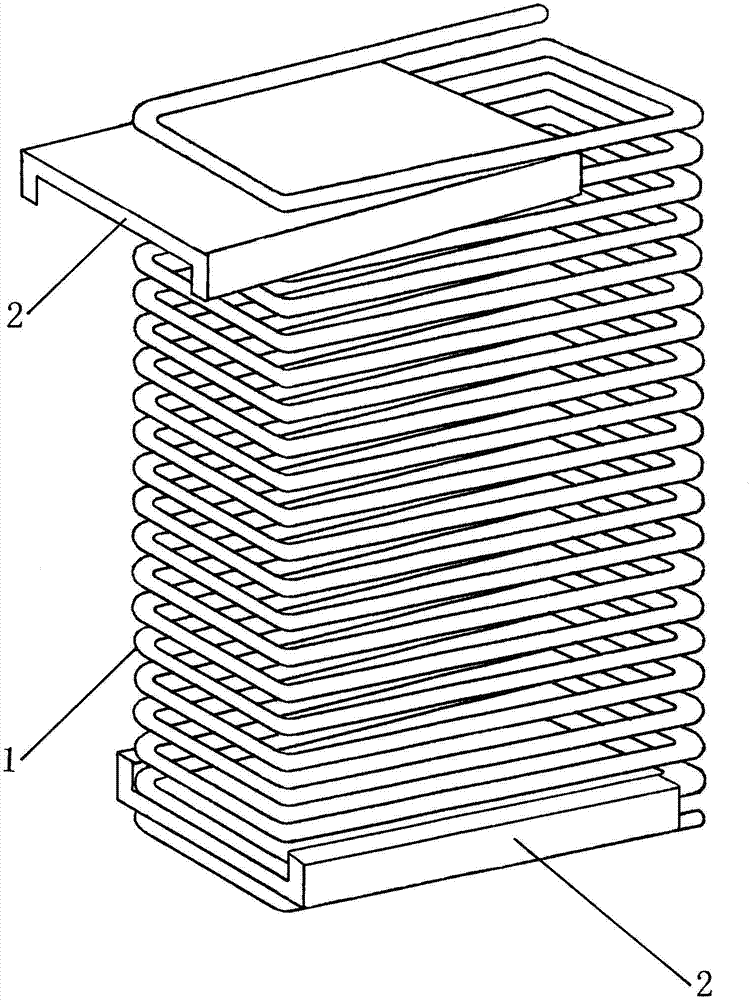

[0013] In the embodiment shown in Fig. 3, the concave metal end cover plate (2) is installed on both ends of the wire king cage (1). Moderately open the concave metal end cover plate (2) on the wire king cage (1), and the queen bee can be easily imprisoned and released from the hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com