Single-pole flux reverse permanent magnet linear motor

A permanent magnet linear motor and magnetic flux reversal technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low power factor, power density and efficiency, poor fault tolerance performance, and high energy index, and achieve The effect of improving reliability and operating capability with faults, reducing manufacturing costs, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

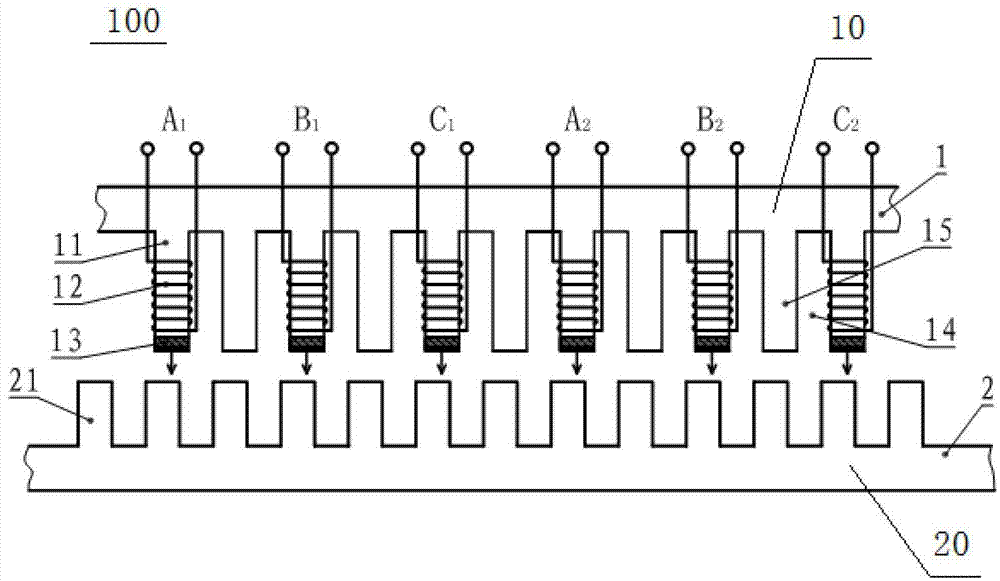

[0031] see figure 2 , figure 2 The structure of the single-pole magnetic flux inversion permanent magnet linear motor according to the embodiment of the present invention is shown.

[0032] The single-pole magnetic flux reversal permanent magnet linear motor 100 includes a mover 1 with a salient pole structure and a stator 2 with a salient pole structure. The mover is composed of a primary iron core 10 , an armature winding 12 and a permanent magnet 13 . The stator is composed of a secondary iron core 20 made of magnetically permeable material.

[0033] There is no winding or permanent magnet on the secondary iron core 20 , and there are multiple salient pole teeth 21 on the secondary iron core 20 .

[0034] The primary iron core 10 is provided with alternately arranged armature teeth 11 and tolerance teeth 15, and slots 14 are formed between the teeth, and the width of all the teeth is the same as the slot width.

[0035] The armature windings 12 are wound on the armatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com