H-shaped metal composite gasket

A metal composite and gasket technology, which is applied in the fields of high-pressure-resistant wound gaskets and high-temperature resistance, can solve problems such as poor deformation resistance, large differences, and catastrophic accidents, and achieve good sealing performance, compensation for unevenness, and easy looseness. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

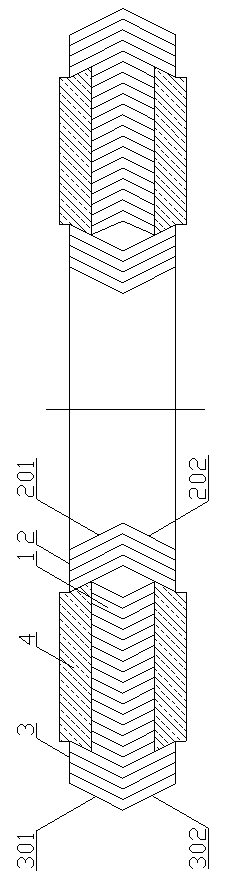

Embodiment 1

[0035] like figure 1 As shown, it includes the pressure bearing ring 1, the initial pressure inner ring 2, and the initial pressure outer ring 3. The initial pressure inner ring 2 and the initial pressure outer ring 3 are respectively located on both sides of the pressure bearing ring 1. 2. The initial pressure outer rings 3 are connected by welding. The pressure bearing ring 1, the initial pressure inner ring 2, and the initial pressure outer ring 3 are formed by winding metal strips respectively, and several points are welded on each circle. The sections of the pressure bearing ring 1, the initial pressure inner ring 2 and the initial pressure outer ring 3 are <-shaped respectively, the initial pressure inner ring 2 and the initial pressure outer ring 3 are of the same height and the <-shaped openings are set opposite to each other, and the <-shaped openings of the pressure-bearing ring 1 are The opening direction is the same as that of the initial pressure outer ring 3 . ...

Embodiment 2

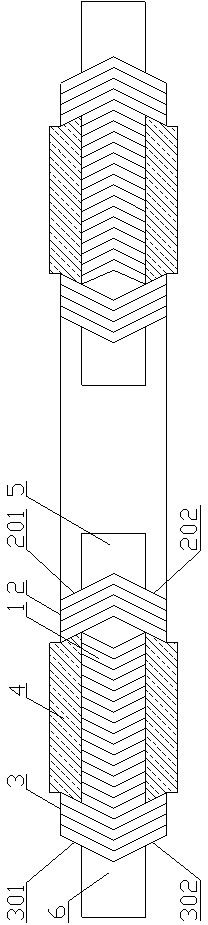

[0038] like figure 2 As shown, it includes the pressure bearing ring 1, the initial pressure inner ring 2, and the initial pressure outer ring 3. The initial pressure inner ring 2 and the initial pressure outer ring 3 are respectively located on both sides of the pressure bearing ring 1. 2. The initial pressure outer rings 3 are connected by welding. The pressure bearing ring 1, the initial pressure inner ring 2, and the initial pressure outer ring 3 are formed by winding metal strips respectively, and several points are welded on each circle. The sections of the pressure bearing ring 1, the initial pressure inner ring 2 and the initial pressure outer ring 3 are <-shaped respectively, the initial pressure inner ring 2 and the initial pressure outer ring 3 are of the same height and the <-shaped openings are set opposite to each other, and the <-shaped openings of the pressure-bearing ring 1 are The opening direction is the same as that of the initial pressure outer ring 3 . ...

Embodiment 3

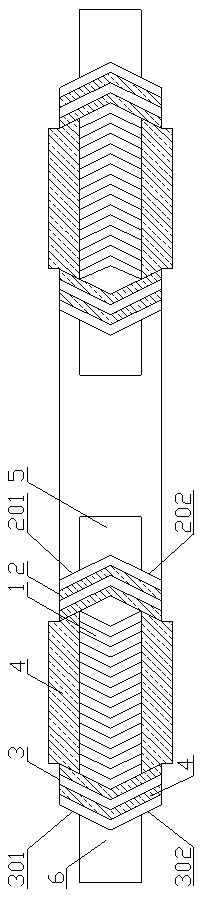

[0041] like image 3 As shown, it includes the pressure bearing ring 1, the initial pressure inner ring 2, the initial pressure outer ring 3, the positioning inner ring 5, and the positioning outer ring 6. The initial pressure inner ring 2 and the initial pressure outer ring 3 are respectively located on both sides of the pressure bearing ring 1 The pressure bearing ring 1, the initial pressure inner ring 2 and the initial pressure outer ring 3 are connected by welding, the positioning inner ring 5 is located inside the initial pressure inner ring 2, and the positioning outer ring 6 is located outside the initial pressure outer ring 3. The pressure ring 1 is formed by winding a metal strip, and several points are welded on every circle. The initial pressure inner ring 2 and the initial pressure outer ring 3 are formed by winding metal strips respectively, and non-metal fillers 4 are arranged between the metal strips, and the metal strips are connected by butt welding. The sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com