Novel axial-flow fan with small-aspect-ratio blades having obliquely-cut and twisted blade roots

An axial flow fan, twisted blade technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as high outlet wind pressure, achieve high supercharging capacity, high bending rigidity, and achieve wind pressure requirements and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

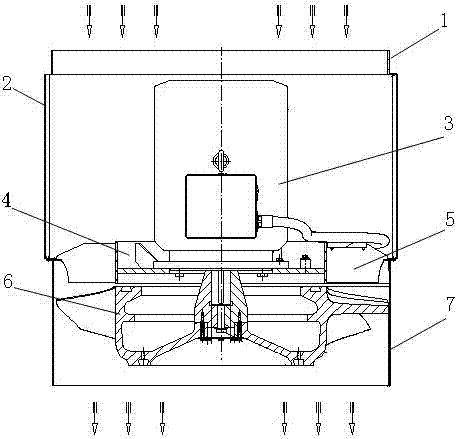

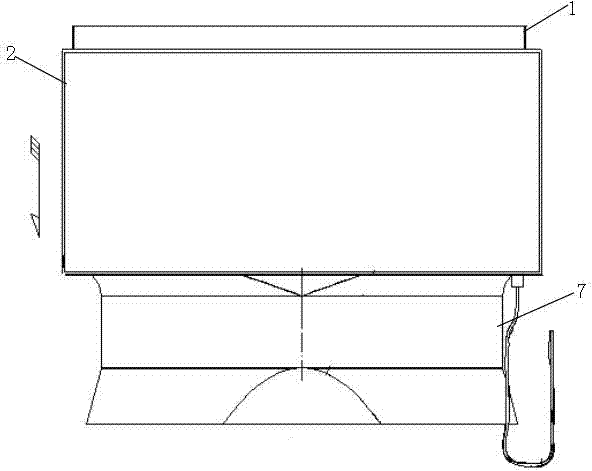

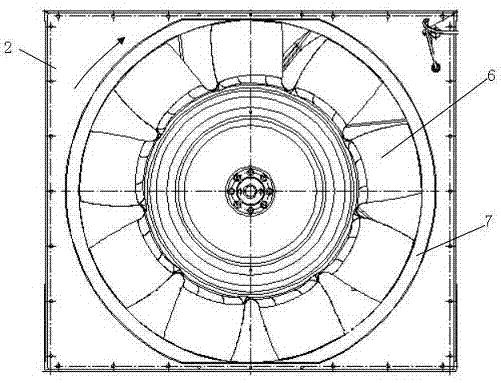

[0030] Such as figure 1 As shown in -4, the novel small-aspect-ratio blade root beveled twisted blade type axial flow fan device of the present invention consists of an air inlet interface 1, an air inlet chamber 2, a drive motor 3, a support ring 4, a support plate 5, and an impeller 6 and exhaust section 7 form. The drive motor 3 is placed on the support ring 4 in the center of the rear part of the air inlet chamber 2, and is directly connected to the impeller 6 through the shaft. The part where the wind section 7 is connected. The inlet of the air inlet chamber 2 is provided with an air inlet connection port 1, which is connected to the front air inlet. The exhaust section 7 is divided into two parts: a cylinder section and a diffuser section, which are closely connected with the air inlet chamber 2 to form the main flow part. . Eight pieces (two groups) of equal-thick support plates 5 with diversion function are welded between the air inlet chamber 2 and the air exhaust...

Embodiment 2

[0034]The basic structure is the same as that of Example 1, suitable for large-flow fans. The wheel-to-hub ratio of the impeller is 0.7. The blades adopt 9 twisted blades with variable cross-section and variable thickness. The aspect ratio is 0.7, and 8 equal-thick support plates are welded. The trailing edge of the blade root is chamfered and rounded, with a cutting angle of 15° and a rounding radius of 20mm.

Embodiment 3

[0036] The basic structure is the same as that of Example 1, which is suitable for fans with small flow rate. The hub ratio of the impeller is 0.5. The blades adopt 12 twisted blades with variable cross-section and variable thickness. The aspect ratio is 0.9, 12 equal-thick support plates are welded, the trailing edge of the blade root is chamfered and rounded, the cutting angle is 20°, and the rounding radius is 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com