Hollow environmentally-friendly cut block

An environmentally friendly and hollow technology, applied in building components, walls, buildings, etc., can solve the problems of not much improvement in structure and difficult positioning, and achieve the effects of short production time, convenient stacking, and enhanced flexibility in application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

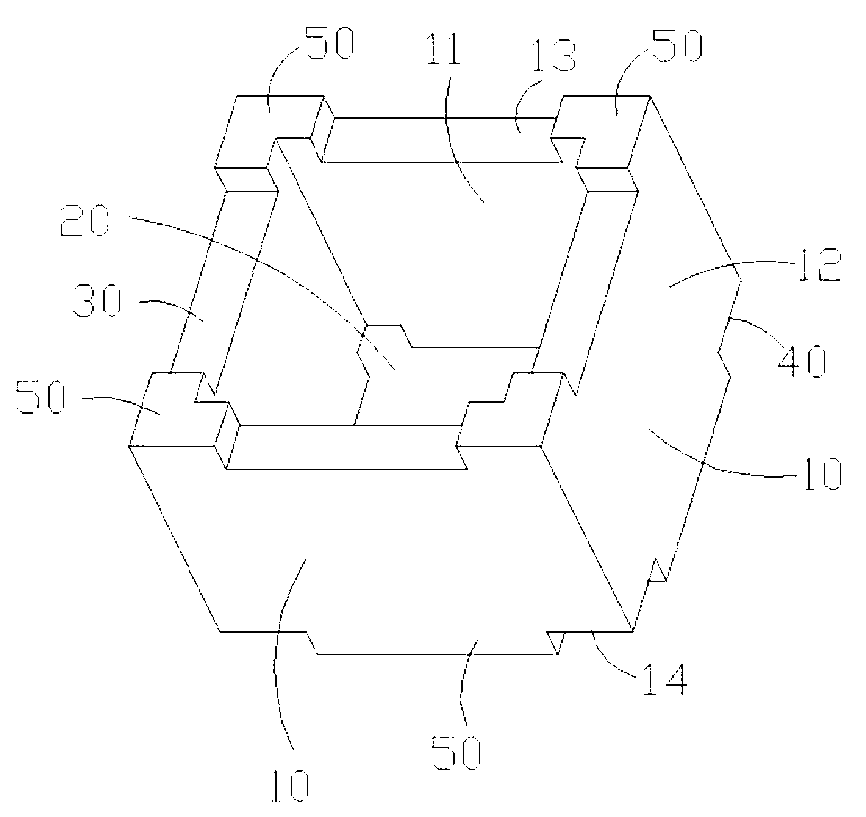

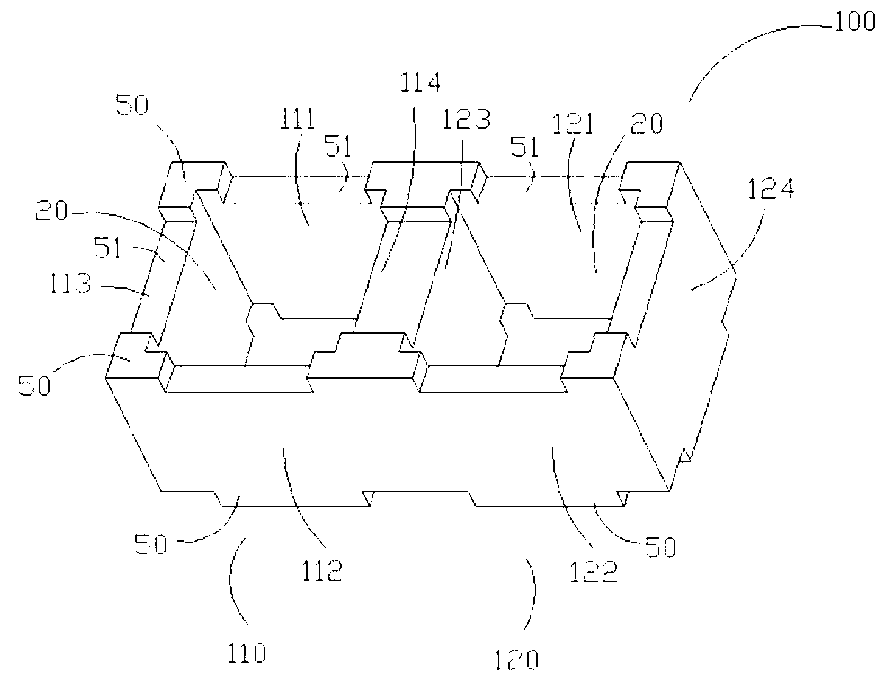

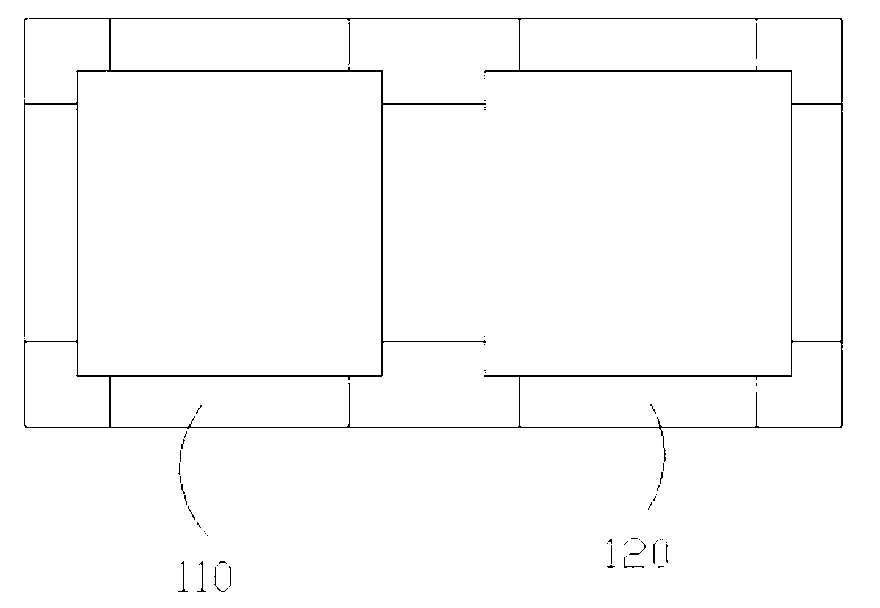

[0034] Such as Figures 1 to 11 As shown, a hollow environmental protection cutting block includes several side wall panels 10 , each of which has an inner surface 11 , an outer surface 12 , a top surface 13 and a bottom surface 14 .

[0035] Several side wall panels 10 are sequentially and fixedly connected together to form the hollow environmental protection cutting block.

[0036] A cavity 20 is formed around the inner surfaces 11 of the plurality of side wall panels 10, and the cavity 20 is located in the middle of the hollow environmental protection block.

[0037] The top surface 30 of the brick body is formed by connecting the top surfaces 13 of several side wall panels 10 .

[0038] The bottom surface 40 of the brick body is formed by connecting the bottom surfaces 14 of several side wall panels 10 .

[0039] Positioning blocks 50 are fixedly arranged on the top surface 30 of the brick body and the bottom surface 40 of the brick body respectively.

[0040] In specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com