Lime slaking device

A lime and digestion tank technology, applied in the field of lime digestion devices, can solve the problems of production cost limitation, time and economic cost increase, etc., and achieve the effects of simple operation, fast reaction speed and higher slag content rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

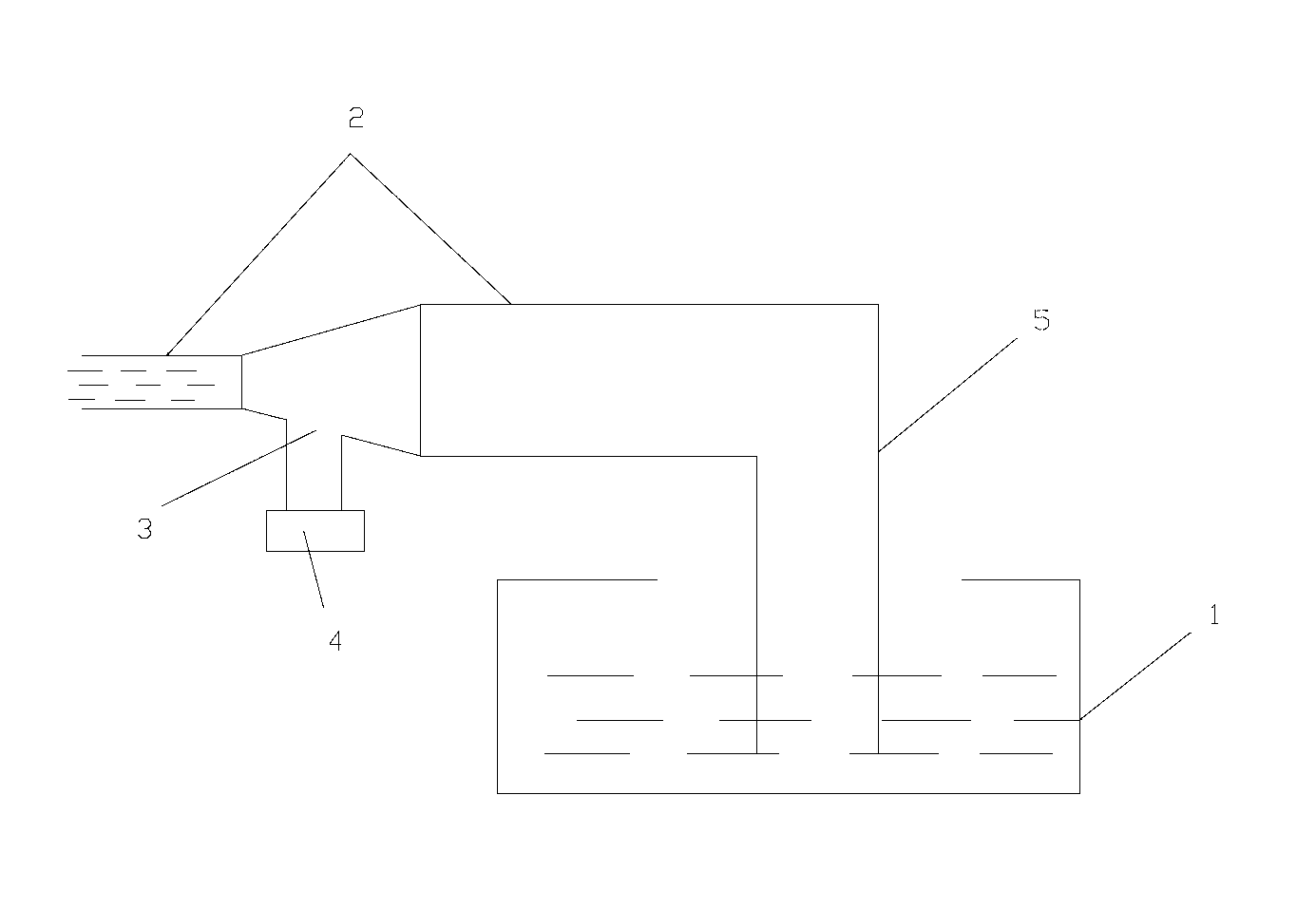

[0011] As shown in the figure, the lime digestion device is composed of a steam pipe 2 and a digester 1. The steam is passed into the digester 1 through the steam pipe 2, and an input port 3 is provided on one side of the steam pipe 2. The steam at the position of the input port 3 The pipe 2 gradually expands along the direction of steam flow, and is connected to the screw conveyor 4 at the input port 3, and the lime is transported into the steam pipe 2 by the conveyor 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com