Fork shrinkage type screw jack

A jack and screw technology, applied in the direction of the lifting device, etc., can solve the problems of bending deformation, danger, failure and other problems of the jack, and achieve the effects of simplified processing, better structure and manufacturability, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiment, which will help the public to understand the technical content and effect of the case, but the description of the embodiment does not constitute a limitation to the technical solution. Any transformation that is merely equivalent in form should be regarded as the scope of the technical solution of this case.

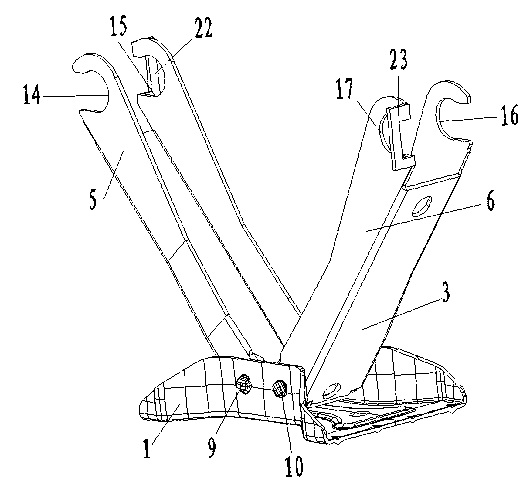

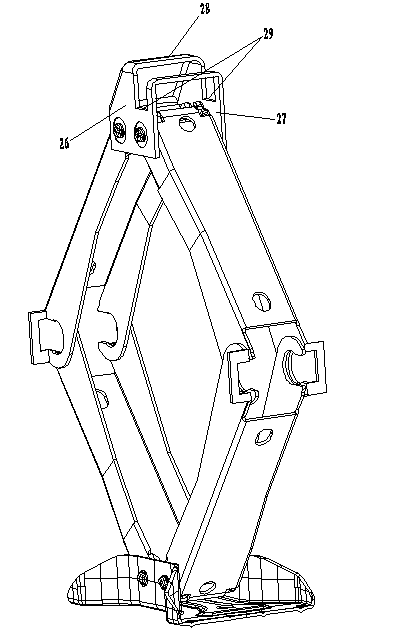

[0026] As can be seen from the accompanying drawings, the embodiment of the present invention is based on the traditional scissor jack, and optimizes the design of each mechanical structure. The paired lower support arm groups 3 are connected with the base 1, and the paired upper support arm groups 4 is connected with the head 2. The first lower supporting arm 5 and the second lower supporting arm 6 are arranged in the lower supporting arm group 3, and the first upper supporting arm 7 and the second upper supporting arm 8 are arranged in the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com