Air cooling mechanism for screw rod

An air-cooled, screw-screw technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the high cost of equipment maintenance and repair, the difficulty of screw manufacturing and processing, and the increase of equipment costs, etc. problems, to achieve the effect of high maintenance and repair costs in the later stage, reducing production costs and reducing manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and through embodiments.

[0038] Example.

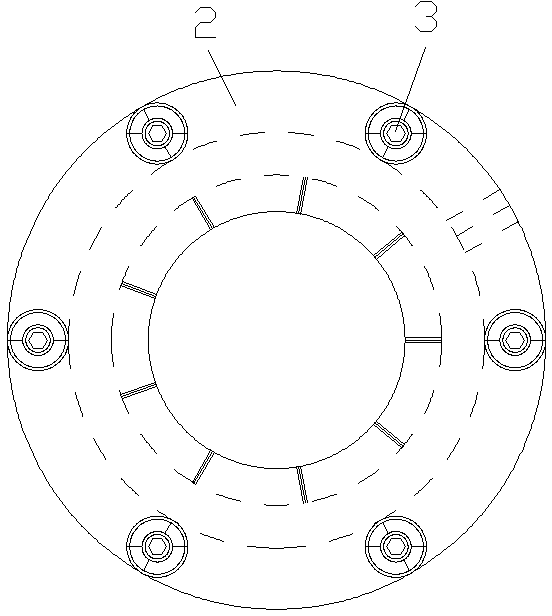

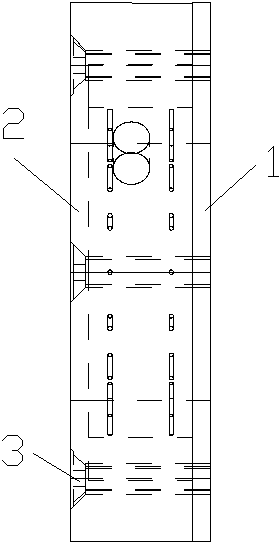

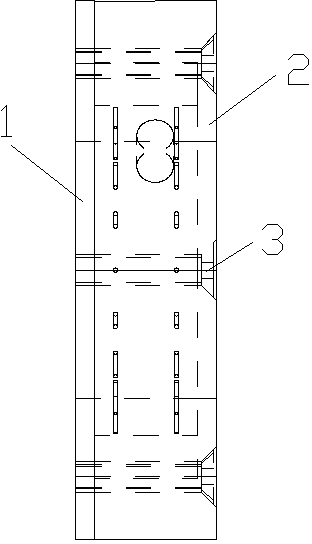

[0039] see Figure 1 to Figure 16 , the screw air cooling mechanism in this embodiment is composed of an inner ring 1, an outer ring 2 and six screws 3. The number of screws 3 in the present invention can be set according to actual needs, and the number of screws 3 is generally three above.

[0040] The inner ring 1 is composed of an inner ring body 11 and an air cooling jacket 12. The inner ring body 11 is a circular ring structure, and an inner ring circular hole 15 is arranged in the center of the inner ring body 11. There are the same number of inner ring connecting holes 14 as screws. A sealing ring 17 is arranged around the inner ring body 11 .

[0041]The air-cooling jacket 12 has a cylindrical structure, and the air-cooling jacket 12 is provided with a screw channel 16, the screw channel 16 is a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com