Welding tool for front collision transverse beam of automobile

A welding tooling and front collision technology is applied in the field of clamping tooling, which can solve the problems of welding and clamping tooling without front collision beam, and achieve the effect of improving welding efficiency and facilitating welding production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

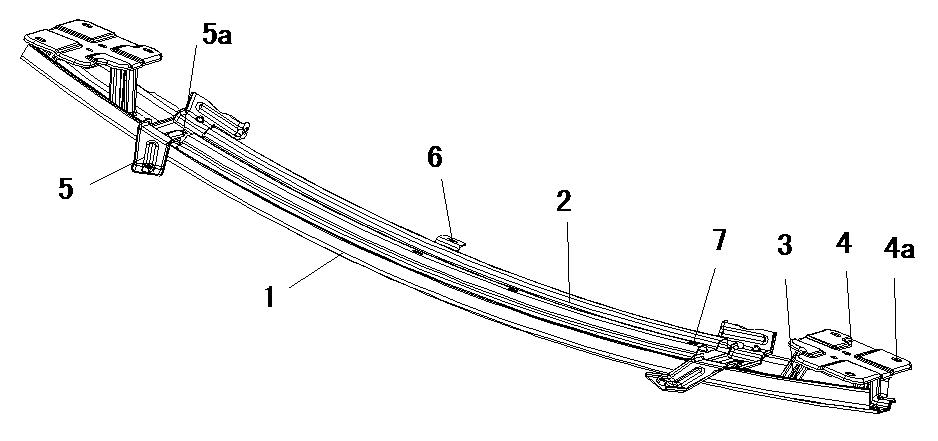

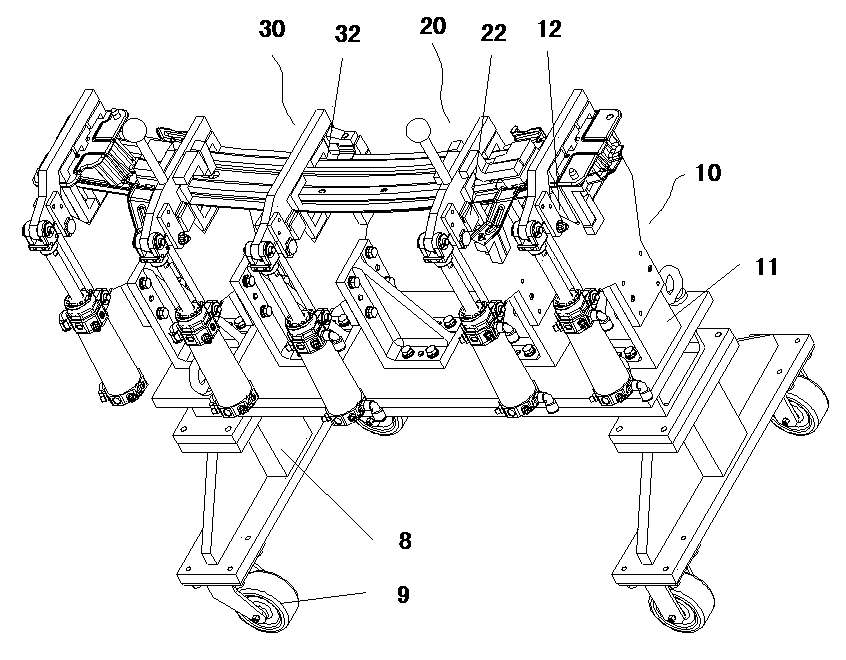

[0025] Such as figure 2 As shown, it is a structural schematic diagram of an embodiment of the automobile front collision beam welding tooling of the present invention. The automobile front collision beam welding tool of the present embodiment comprises a base 8, and the base 8 is provided with two clamping devices 110 corresponding to the welding assembly of the front crash box, and a device corresponding to the side lock plate 5. Clamping device II 20 and clamping device III 30 for clamping and positioning lug plate 6.

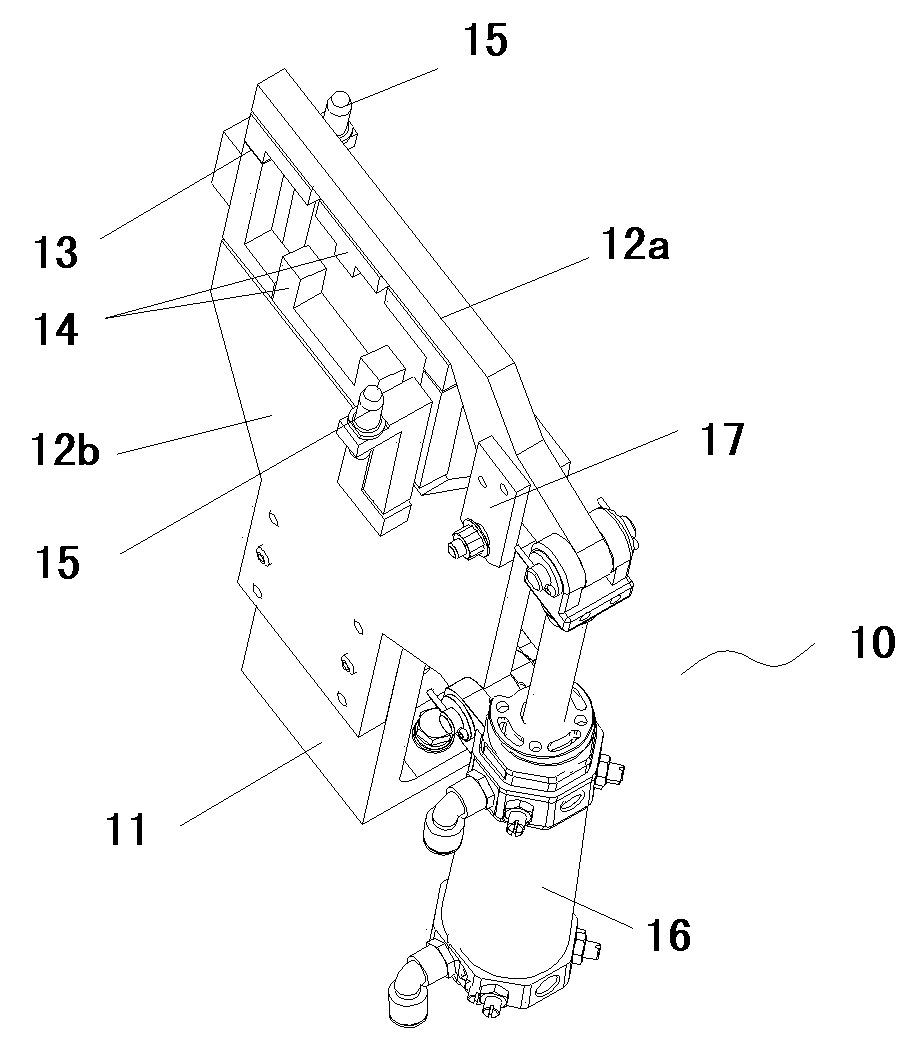

[0026] The clamping device I 10 includes a bracket I 11 fixedly installed on the base 8, the bracket I 11 is provided with a chuck I 12, and the chuck I 12 includes a clamp for pressing and fixing the front crash box welding assembly on the outer panel 1. The upper clamp I 12a and the lower clamp I 12b are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com