Method for efficiently reducing granularity of 5A molecular sieve (MS)

A molecular sieve and particle size technology, applied in the field of molecular sieve, can solve the problem that MS nitrogen production technology cannot exert higher economic benefits, and achieve the effect of speeding up the adsorption speed, shortening the adsorption period and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for efficiently reducing the particle size of 5A molecular sieves, the steps are as follows:

[0034] ⑴The 5A molecular sieve purchased from Huiying Chemical Industry (Quanzhou) Co., Ltd. has an average particle size of 5.0μm and a total specific surface area of 640.6m 2 / g, the micropore specific surface area is 555.7m 2 / g.

[0035] (2) Add 55g of absolute ethanol to 291g5A molecular sieve, the addition amount is 25%, mix well,

[0036] (3) Disperse in 209g of distilled water, with a solid content of 43%, and stir evenly;

[0037] (4) The particle size of the grinding medium is 1mm;

[0038] (5) Perform shearing treatment for 15 minutes at a speed of 3600 rpm.

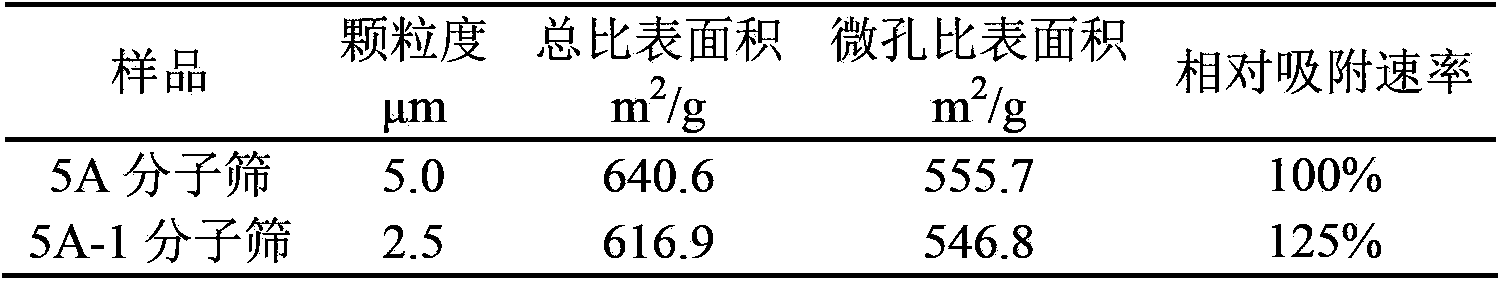

[0039] (6) Then use the Mini Motormill250 produced by Eiger Machinery Inc. to mark it as 5A-5 after treatment, measure the molecular sieve particle size, total specific surface area and micropore specific surface area, and calculate the relative adsorption speed. The data are as follows;

[004...

Embodiment 2

[0044] A method for efficiently reducing the particle size of 5A molecular sieves, the steps are as follows:

[0045] ⑴The 5A molecular sieve purchased from Huiying Chemical Industry (Quanzhou) Co., Ltd. has an average particle size of 5.0μm and a total specific surface area of 640.6m 2 / g, the micropore specific surface area is 555.7m 2 / g.

[0046] (2) Add 55g of absolute ethanol to 291g5A molecular sieve, the addition amount is 25%, mix well,

[0047] (3) Disperse in 209g of distilled water, with a solid content of 43%, and stir evenly;

[0048] (4) The particle size of the grinding medium is 1mm;

[0049] (5) Perform shearing treatment for 30 minutes at a speed of 3600 rpm.

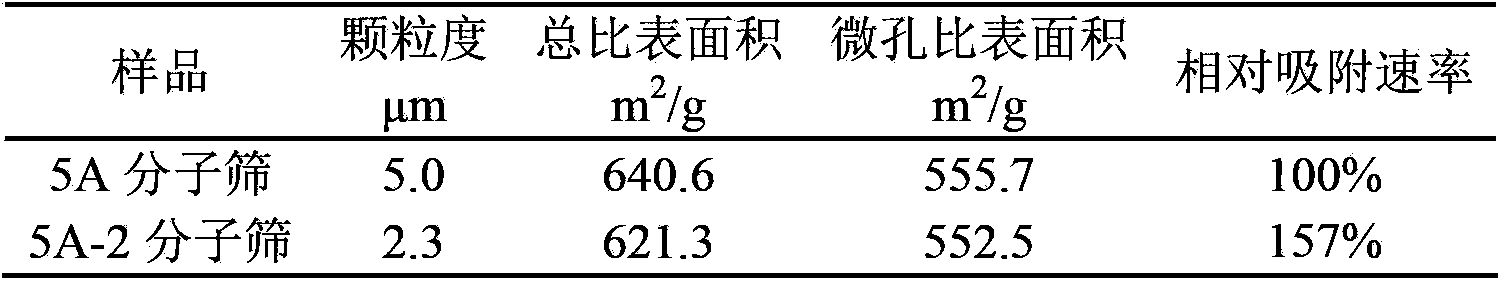

[0050] (6) Then use the Mini Motormill250 produced by Eiger Machinery Inc. to mark it as 5A-5 after treatment, measure the molecular sieve particle size, total specific surface area and micropore specific surface area, and calculate the relative adsorption speed. The data are as follows;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com