Quantitative feeder for lactating sow

A technology for sucking sows and feeders, applied in the field of feeders, can solve the problems of increased labor intensity, waste, moldy feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the structural principles of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

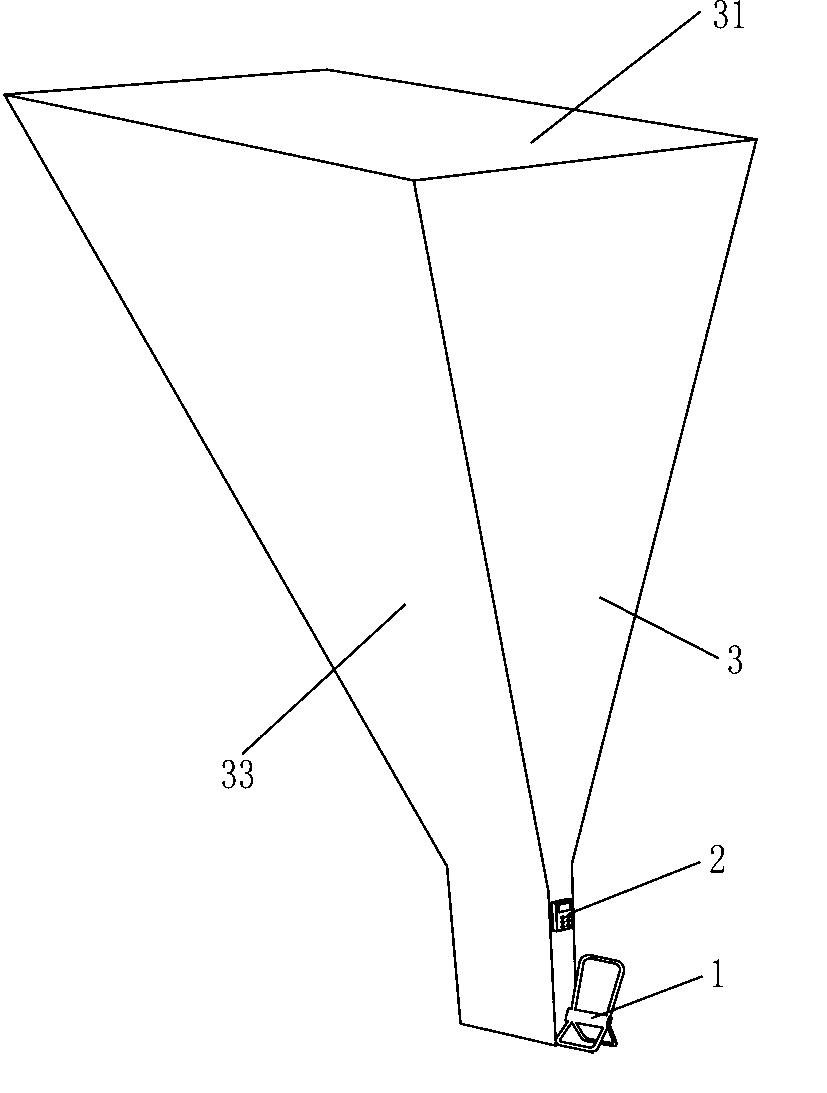

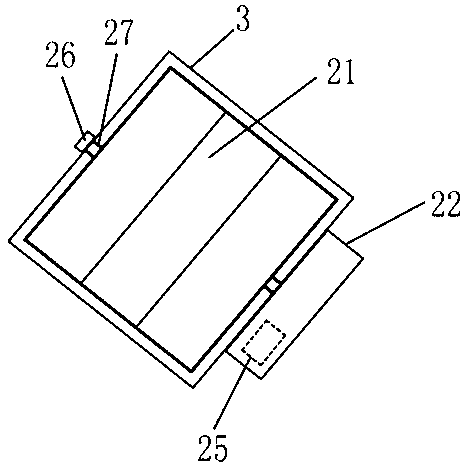

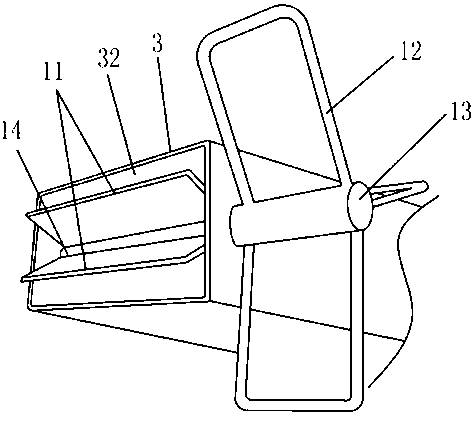

[0020] Such as Figure 1-Figure 5 Shown, a quantitative feeder for lactating sows, it includes a storage feeder and a feeding trough, the storage feeder is provided above the feeding chute, and the storage feeder includes a rotary feeder Device 1 and storage tank 3, the top of the storage tank 3 is provided with a cylinder cover 31, the bottom is provided with a discharge port 32, the discharge port 32 is provided with a rotary feeding device 1, the rotary lower The feeding device 1 includes a plurality of storage plates 11, a rotating handle 12 and a rotating shaft 13. The rotating shaft 13 is installed on the two side panels of the storage tank 3 through bearings, one end is provided with an adjusting screw, and the other end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com