Floor pan for high-speed trains

A technology for high-speed trains and trays, applied in the field of rail transit, can solve problems such as affecting train operation, achieve simple assembly/disassembly, achieve reliability, and reduce vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

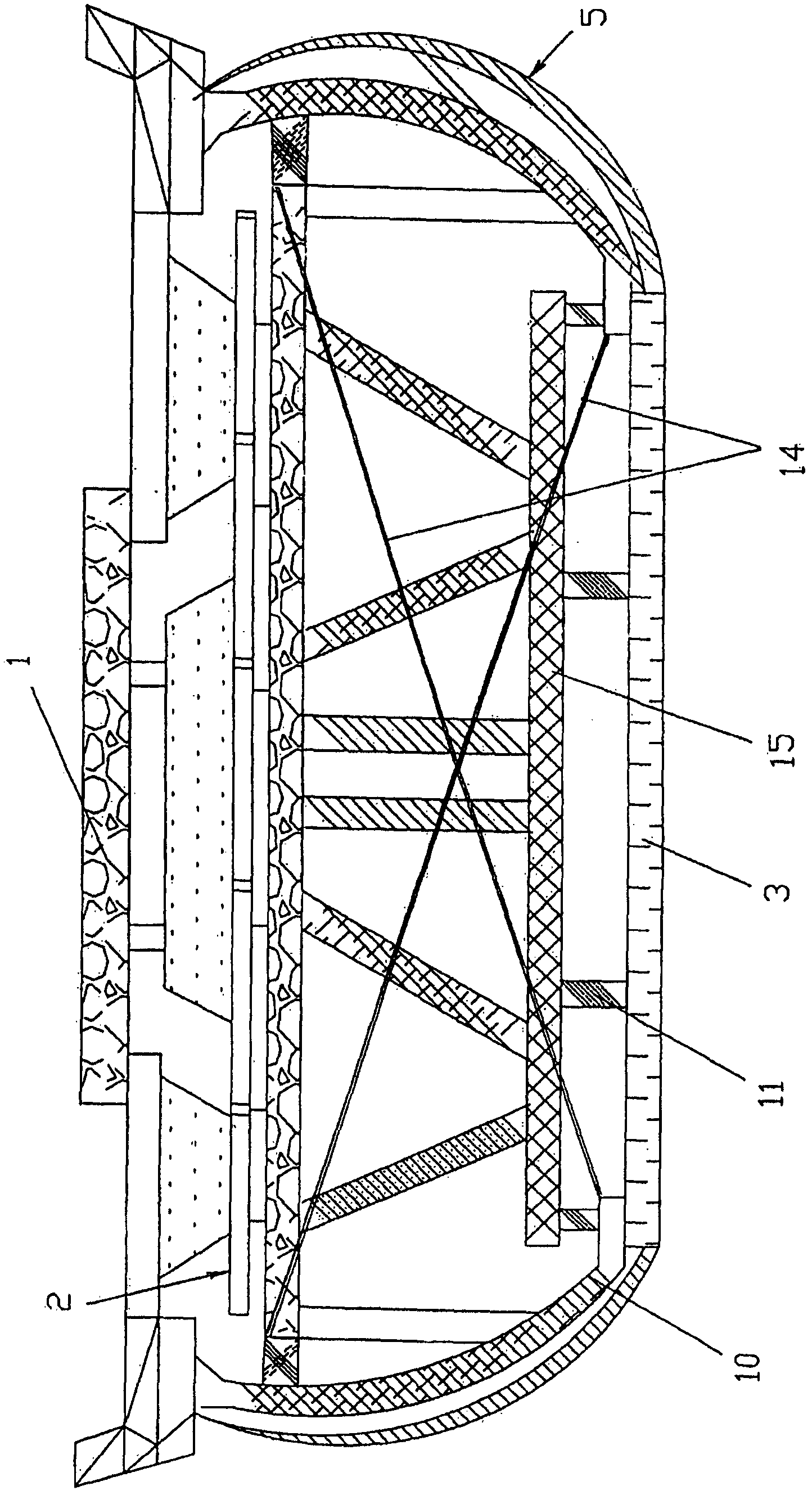

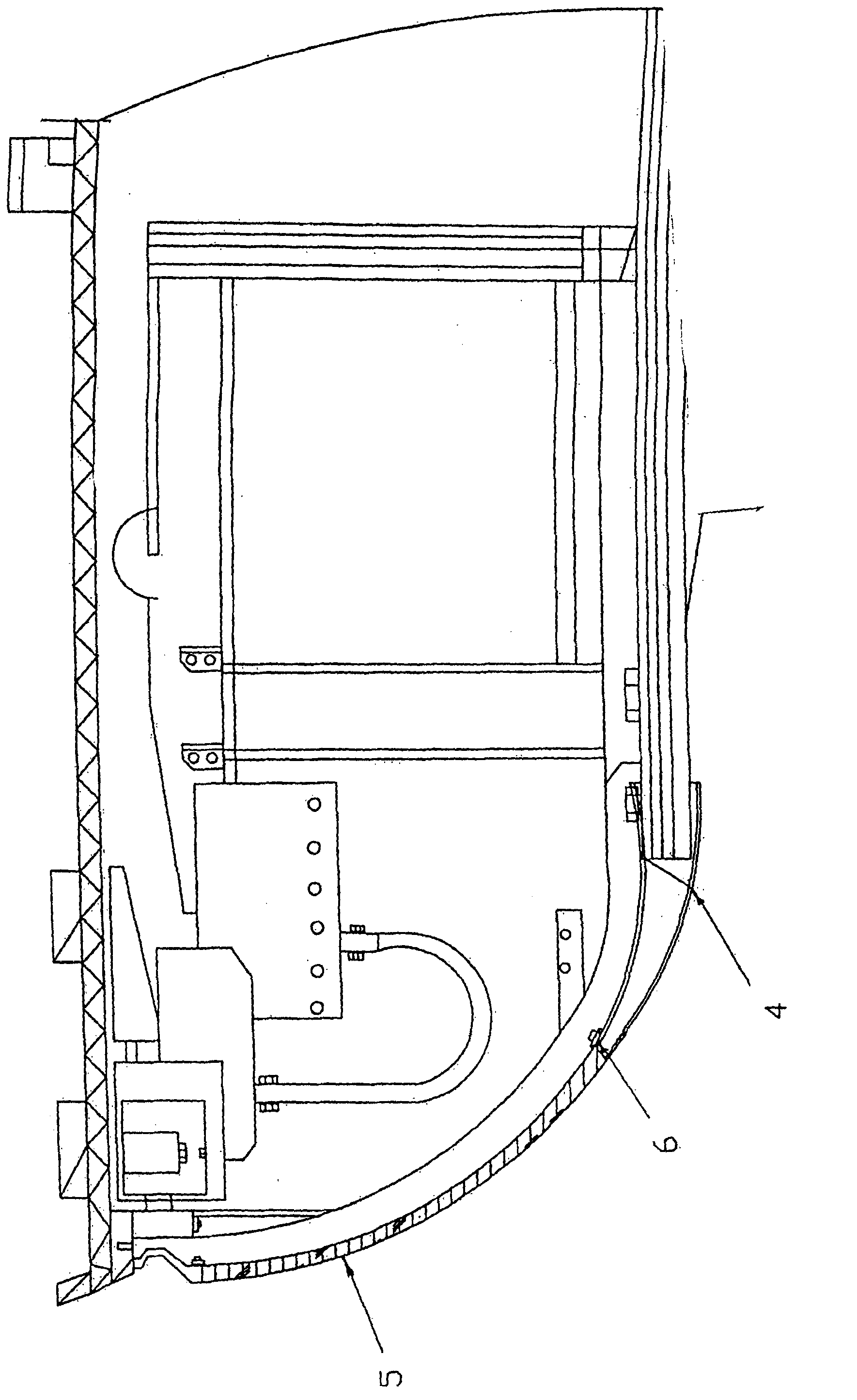

[0014] The provided shallow dish-shaped floor for HGV trains is arranged under the floor 1 of the carriage over the entire length of the floor and is formed as a support 2 (see image 3 ), the bracket is covered by means of a protective base plate 3 and a lateral load-bearing wall 4, which has a side plate fixed thereon (see figure 1 , 2 ). The side panels 5 are designed as a unit and are detachably mounted on the side walls 4 by means of detachable connections. The detachable connection means are constituted as bolts 6, wherein each bolt is arranged inside a pot 7 (see FIG. 5) of a pot fixed in the side plate, said pot having a device on its inner face for Locking ring 8 which prevents the screw 6 from falling out, wherein the cup is screwed into the holder and locked in the holder by means of a nut-shaped locking element 9 .

[0015] The brackets are arched supports 10, which are respectively connected to the longitudinal beams 11 of the HGV train car in opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com