Connection method and structure for casting wall body and plate girder of powerhouse of hydropower station by stages

A technology for hydropower plants and connection methods, which is applied in the direction of hydropower stations, hydropower, traditional hydropower energy, etc., can solve problems such as unreasonable indwelling positions, achieve optimal construction joint positions, strong structural integrity, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

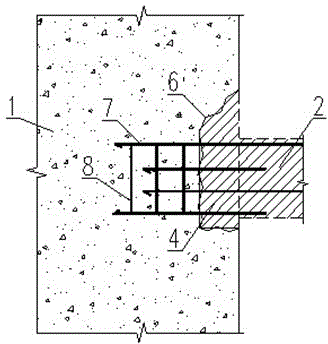

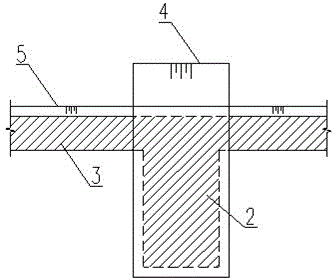

[0015] According to the present invention, a slab girder of a hydroelectric power station is reserved for inserting ribs, such as figure 1 , figure 2 and image 3 As shown, the beam inserting rib groove 4 and the plate inserting rib groove 5 are arranged on the first poured concrete wall 1, and the beam inserting rib groove 4 and the plate inserting rib groove 5 are embedded in the first poured concrete wall 1 to form a groove shape, so that the The construction joint between the plate beam and the wall is moved into the wall body. In the beam inserting rib groove 4 and the plate inserting rib groove 5, there are respectively provided with the post-cast beam 2 and the post-cast plate 3 anchored into the pre-cast concrete wall 1 and poured with the post-cast beam 2 and the post-cast plate 3 to form a whole. Inserting ribs, and between the beam inserting rib groove 4 and the plate inserting rib groove 5 and the first poured concrete wall 1 is provided with the beam inserting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com