A prefabricated steel casing underground diaphragm wall and its construction method

A technology of underground diaphragm walls and steel casings, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complicated wet operation procedures, difficult quality assurance, and long construction period, and reduce the instability of the groove wall , material saving and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

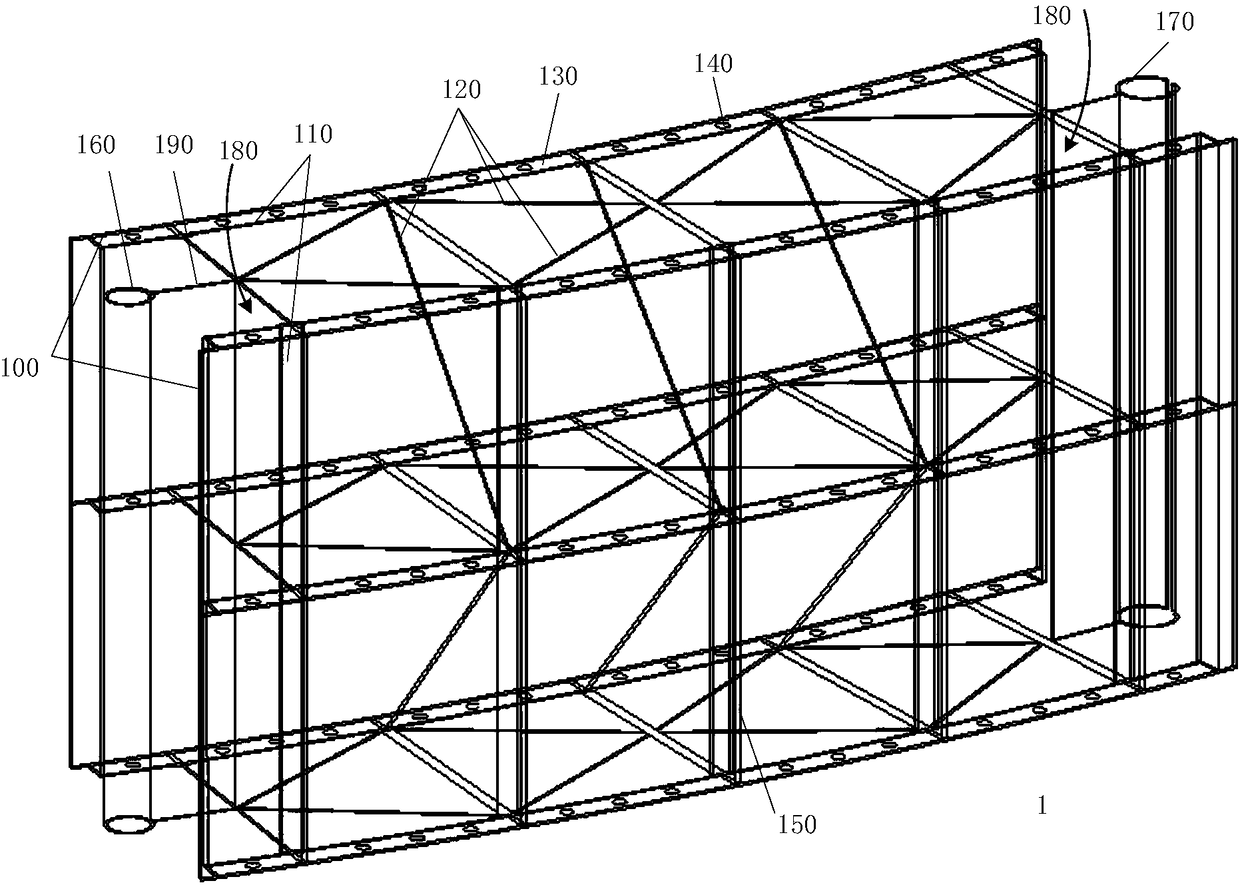

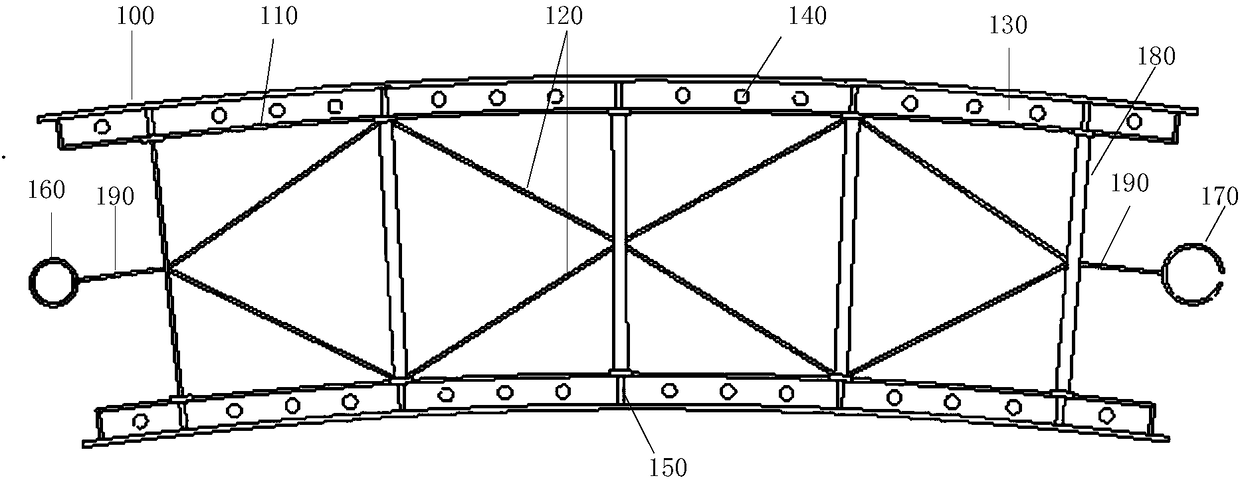

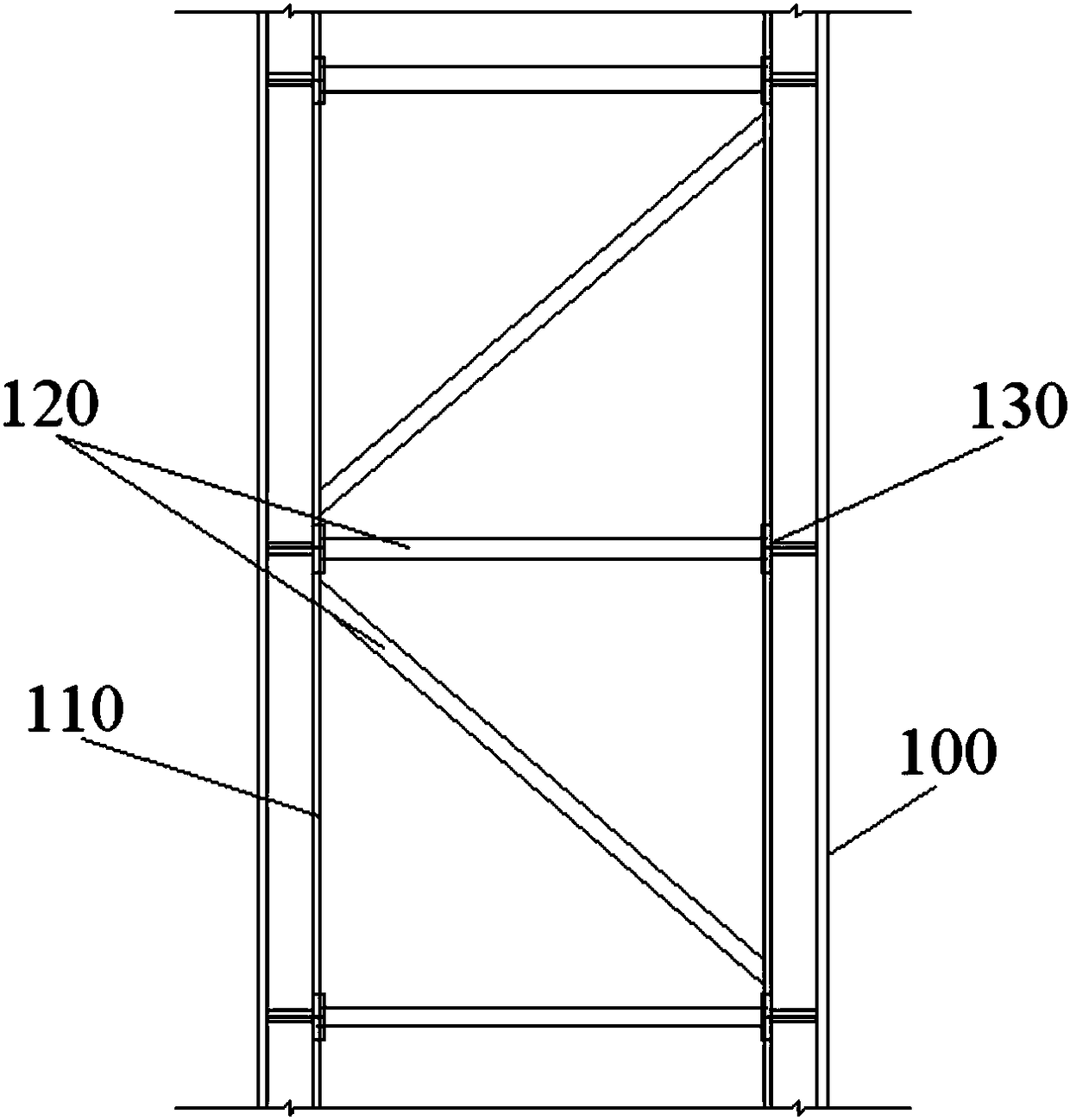

[0039] The prefabricated steel jacket box underground diaphragm wall and construction method thereof of the present invention will be described in more detail below in conjunction with schematic diagrams and flow charts, wherein a preferred embodiment of the present invention is represented, and it should be understood that those skilled in the art can modify the present invention described herein invention, while still realizing the beneficial effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

[0040] In the following paragraphs the invention is described more specifically by way of example with reference to the accompanying drawings. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com