Online amorphous ribbon conveying equipment and realization method thereof

A technology of amorphous strip material and conveying equipment, which is applied in the direction of coiling strip material, transportation and packaging, and thin material processing, etc. Low efficiency, optimized coiling process, and improved material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

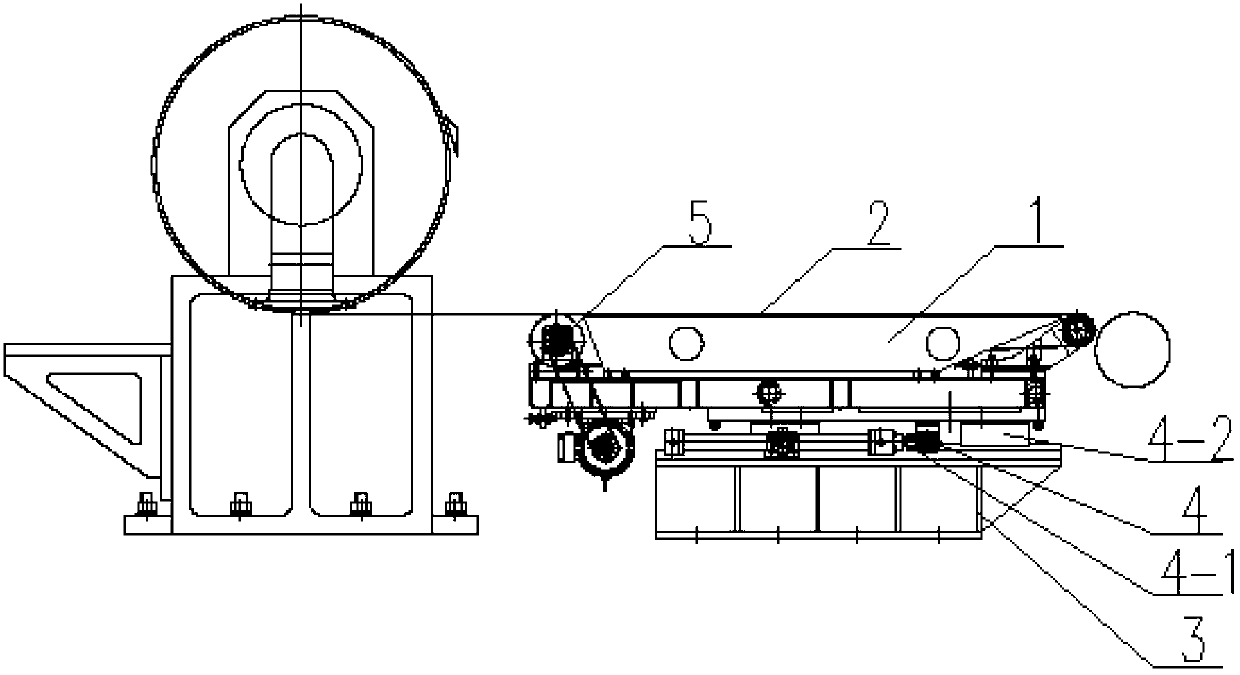

[0012] figure 1 is a schematic structural diagram of an online conveying device for an amorphous strip according to an embodiment of the present invention.

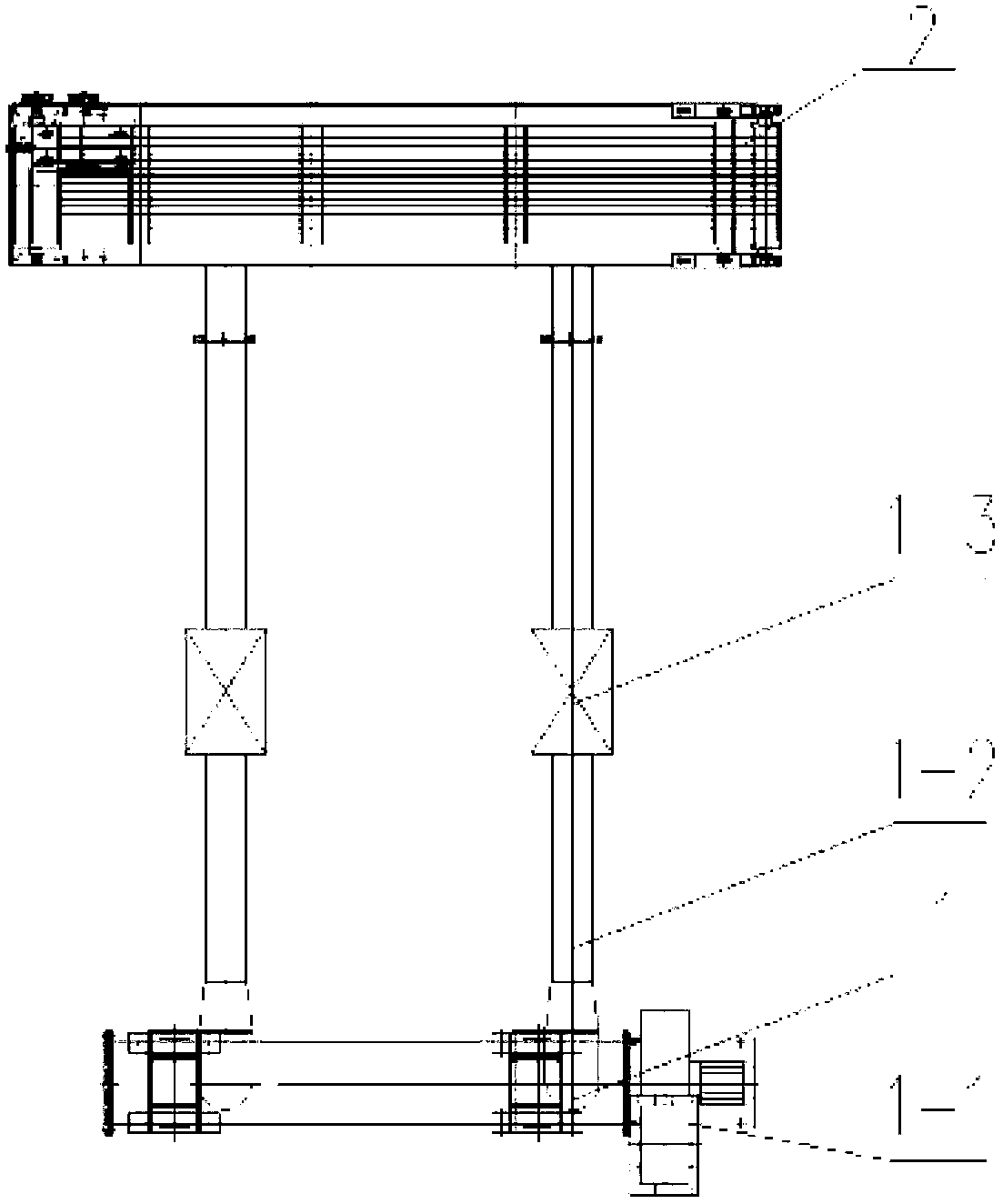

[0013] Such as figure 1 As shown, the structural diagram of this embodiment includes a wind power system 1, multiple sets of conveyor belts 2, a base 3, a distance fine-tuning system 4 and a transmission module 5, wherein the wind power system 1, multiple sets of conveyor belts 2, distance fine-tuning systems 4, The transmission modules 4 are all installed on the frame 3 .

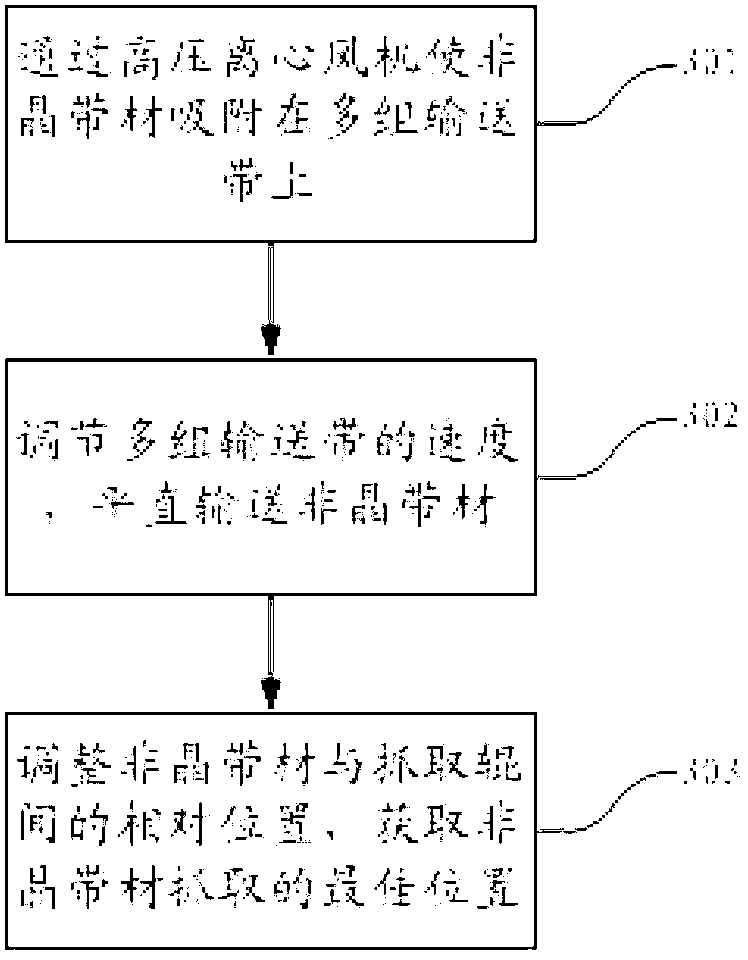

[0014] The wind power system 1 is used to flatten and absorb the amorphous strip that has left the tape-making roller on multiple sets of conveyor belts 2. The wind power system 1 can include a high-pressure centrifugal fan 1-1, a pipeline 1-2, and a pneumatic gate Valves 1-3 and suction bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com