An electric heating method for mosquito removal and its structure

An electric heating and mosquito-killing technology, which is applied to devices, applications, and fumigators for capturing or killing insects. Mosquito repellent is scientific and effective, has little harmful effect on the human body, and saves the effect of mosquito removal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

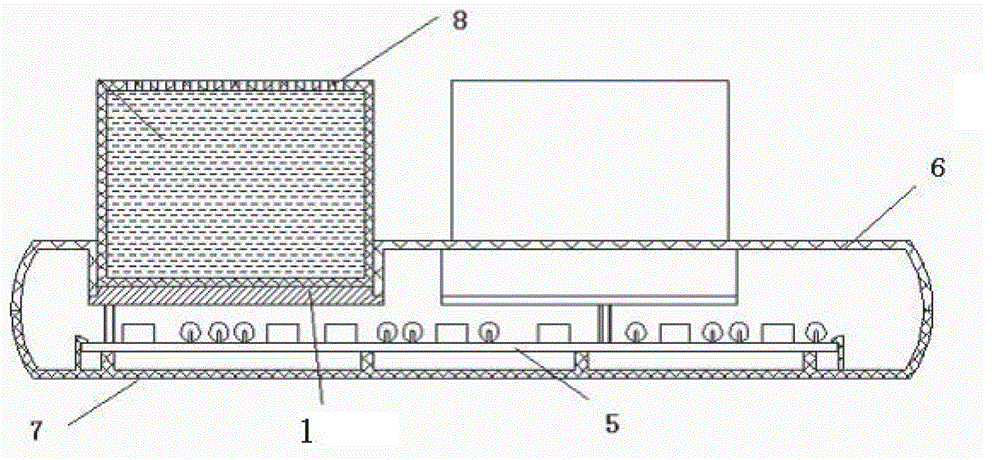

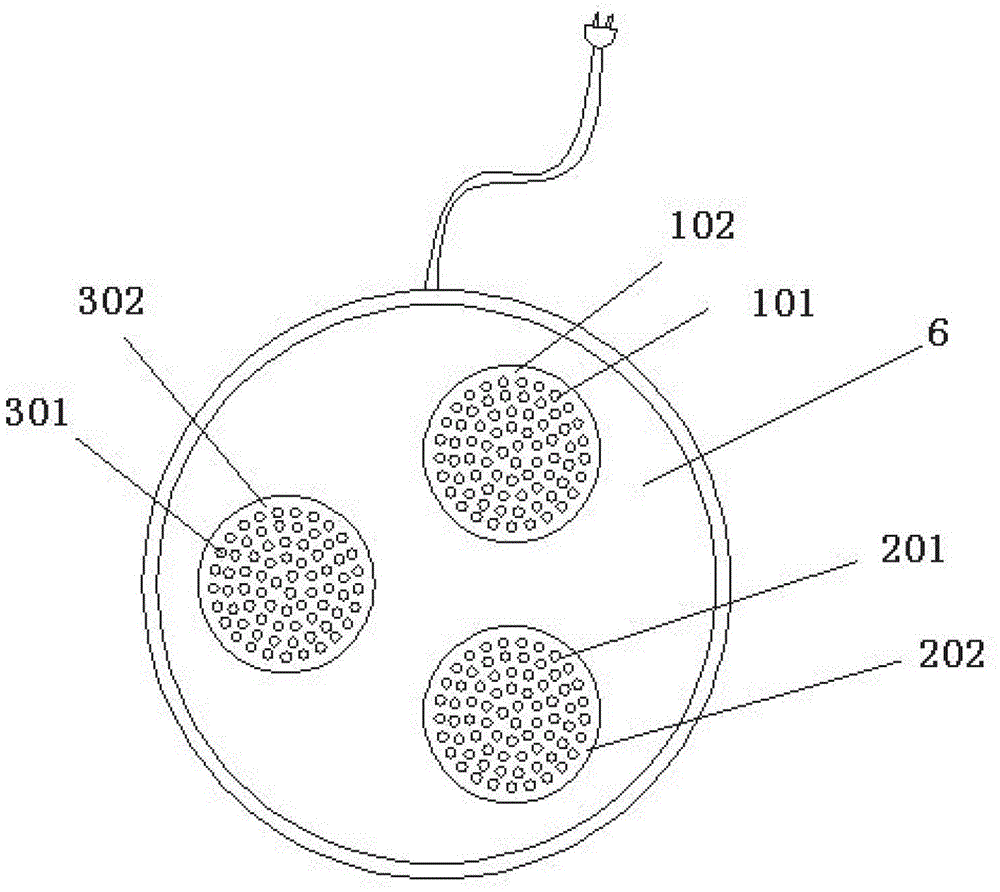

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0025] refer to figure 1 and figure 2 Shown, a kind of electrothermal mosquito removal method is characterized in that, comprises the following steps:

[0026] Step 1) The heating component 1 heats the mosquito repellent material container 102, distributes the mosquito repellent material 101 quickly within the set time, and stops heating after the set time expires;

[0027] Step 2) The heating unit 1 heats the anti-mosquito material container 202, distributes the anti-mosquito material 201 quickly within the set time, and stops heating after the set time expires;

[0028] Step 3) The heating component 1 heats the mosquito-attracting material container 302, and distributes the mosquito-attracting material 301 briefly and slowly within a set time, so as to induce the unkilled mosquitoes in and near the coverage area of the mosquit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com