Offset printing spot color ink color matching method considering cost factor

A cost factor and ink technology, which is applied in printing, printing machines, color measuring devices, etc., can solve the problems of not considering the cost of color matching ink, and can not effectively reduce the cost of ink, so as to improve the efficiency of color matching, reduce the cost of printing production, and the accuracy of color matching precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for matching offset printing spot color inks in consideration of cost, the method comprising the following steps:

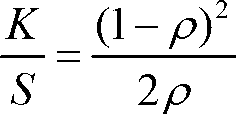

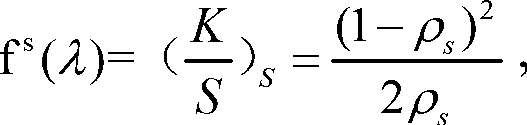

[0024] Step (1): Save to the database, that is, save the price parameter P of all base color inks participating in color matching i , (i=1,2,...,M), M represents the number of base color inks involved in color matching, and the price parameter P i It can be obtained through market research, or obtained from the manufacturer. The base color ink is fluorescent ink or offset printing ink; use a spectrophotometer to read the spectral reflectance value ρ of the sample to be prepared s ; Use a spectrophotometer to read the spectral reflectance value ρ of the substrate t , the substrates are printing substrates and blank substrates;

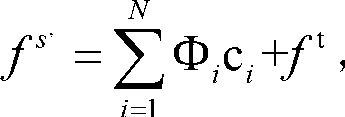

[0025] Step (2): The purpose of building a database is to obtain Φ, which is used to characterize the color matching parameters of each ink participating in color matching, that is, the ink unit concentration value matr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com