Full automatic printing gob feeder

A fully automatic and printing technology, applied in the direction of processing textile materials equipment configuration, etc., can solve the problems of enterprise economic loss, easy to scatter outside, poor accuracy of manual color matching, etc., to prevent oxidative deterioration, avoid working environment, and improve proofing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

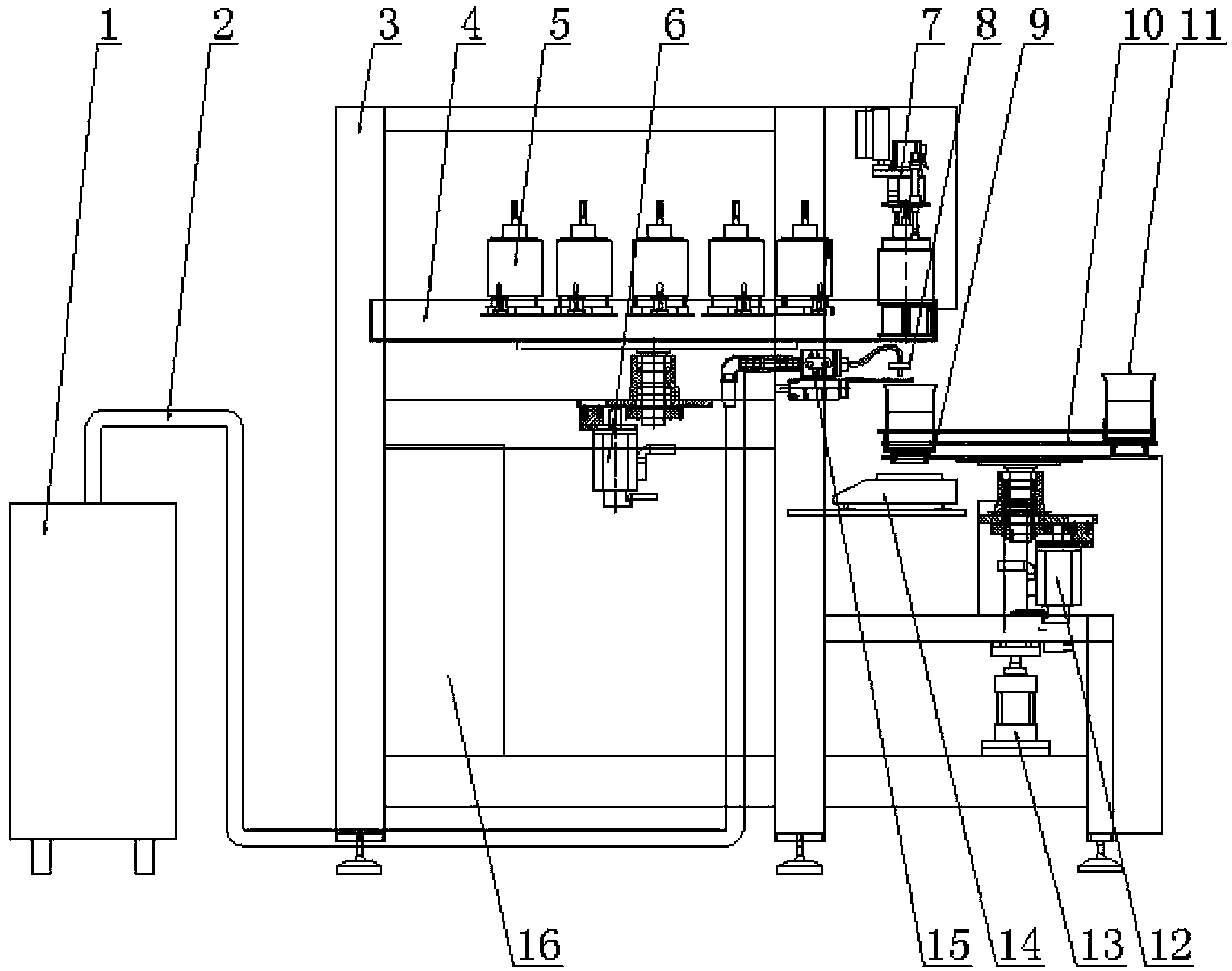

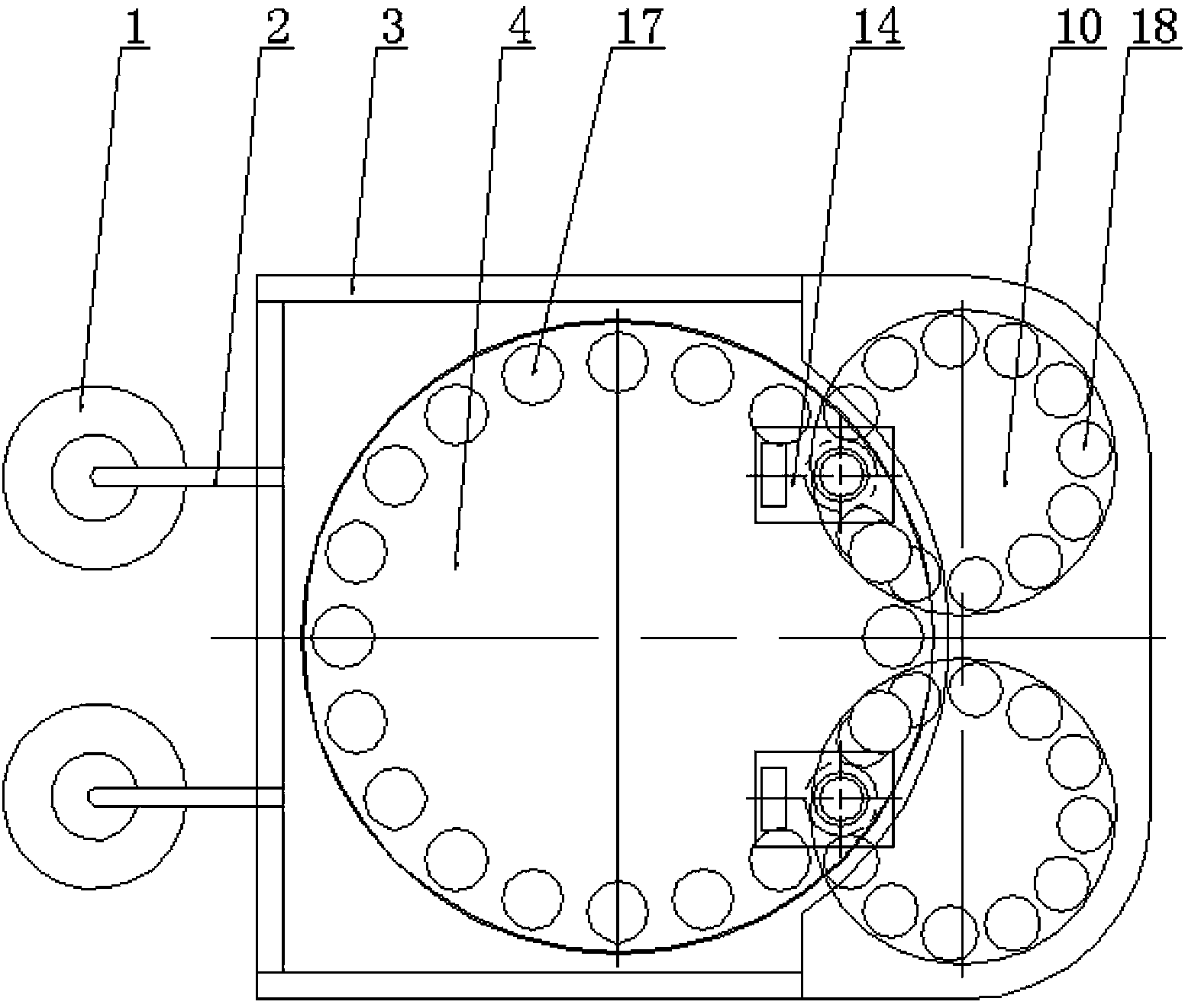

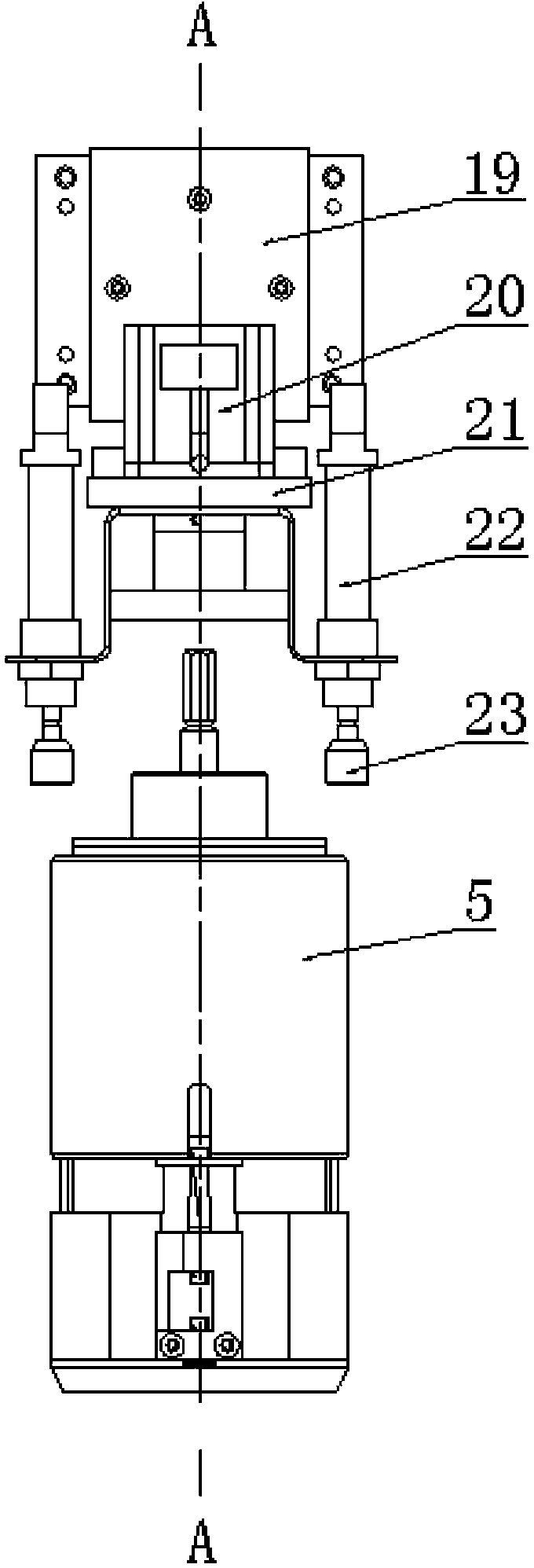

[0035]A fully automatic printing dripping machine, which includes a frame 3, a powder tank rotating device, two powder feeding devices 7, two sample cup rotating devices, two metering devices 14, two auxiliary agent supplying devices 15 and electrical Control device 16; The metering device in the present embodiment is an electronic scale; The powder tank rotating device is installed on the top of the frame, and the powder tank rotating device includes a powder tank 5, a first motor 6, and a first turntable 4, and the powder tank is installed on the first In the clamping hole 17 of the turntable, the first motor drives the first turntable to rotate; the lower part of the frame corresponds to two sample cup rotating devices installed side by si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com