Truck anti-crawling absorber assembly process

An assembly process and anti-snaking technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult positioning and clamping of workpieces, achieve high assembly accuracy, improve production efficiency, and reduce clamping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with examples. However, the invention is not limited to the examples given.

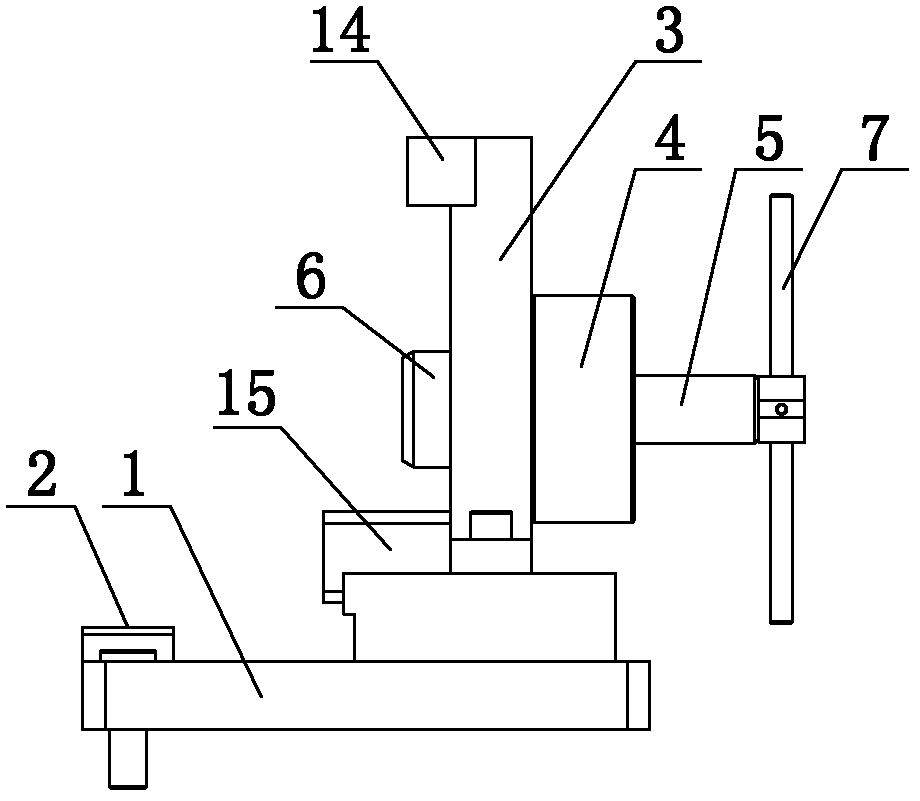

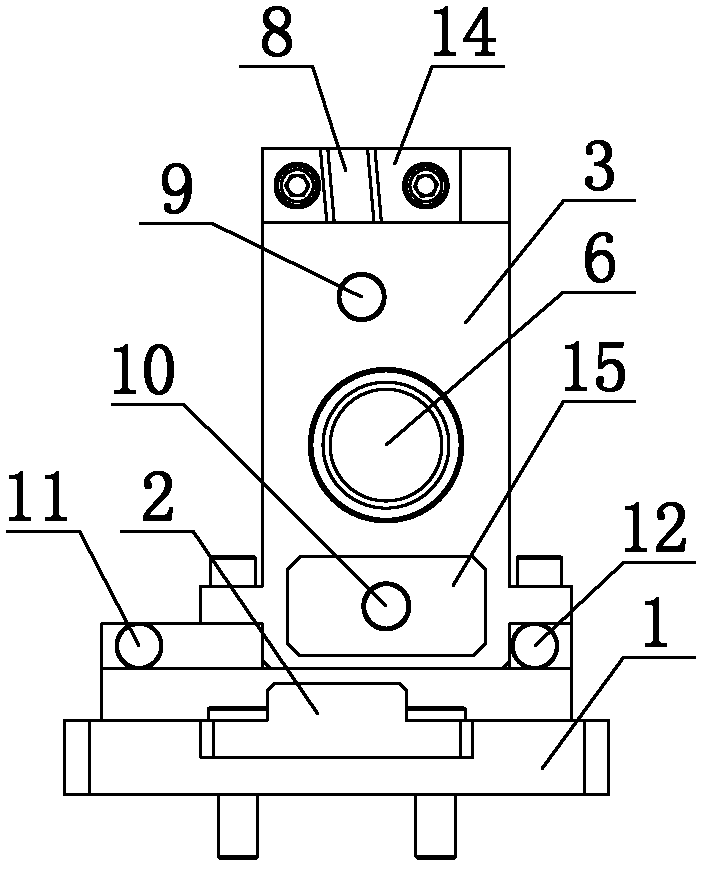

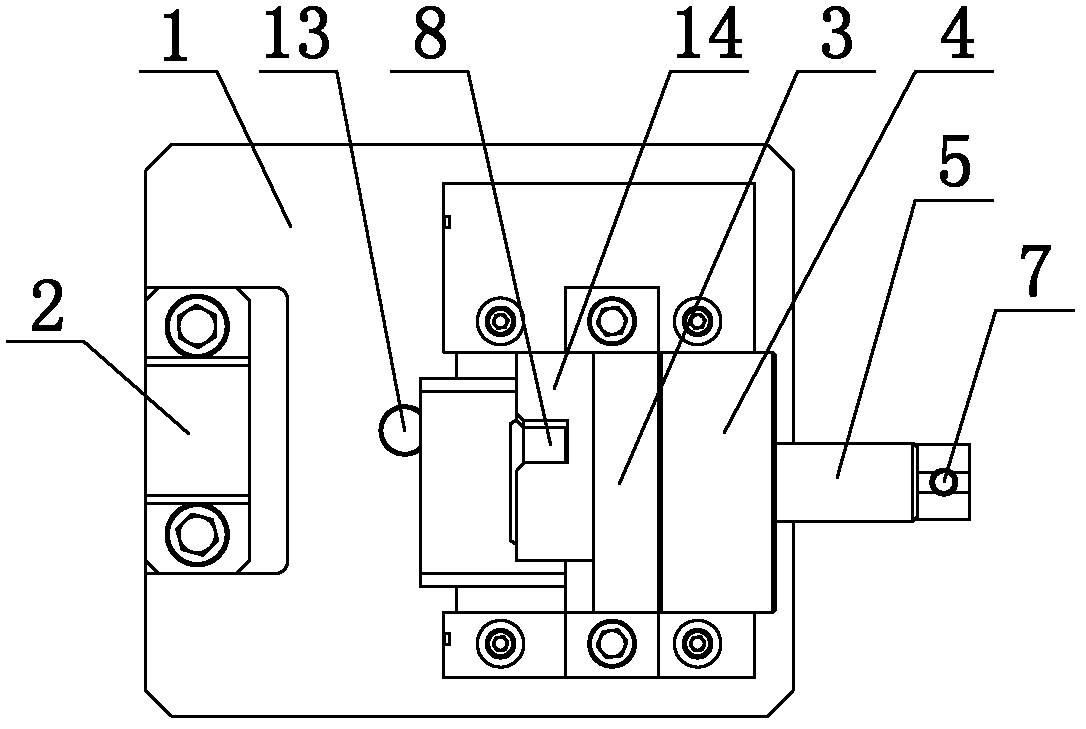

[0020] The bogie anti-snaking shock absorber assembly tooling involved in this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a base plate seat 1, a positioning block 2 corresponding to the base plate groove of the anti-snaking shock absorber and a positioning bracket 3 are arranged on the base plate base 1, and a fixing nut 4 is provided on the outer surface of the positioning bracket 3, inside the nut 4 A lead screw 5 is provided, the front end of the lead screw 5 is provided with a positioning pin 6, the positioning pin 6 is matched with the positioning hole of the torsion bar of the anti-snaking shock absorber, the rear end of the lead screw 5 is connected to the handle 7, and the top of the positioning bracket 3 is used for In the limiting groove 8 at the end of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com