Thermos cup

A technology of thermos cups and lids, applied in the field of thermos cups, can solve the problems of poor thermal insulation performance, poor thermal insulation performance, and poor thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

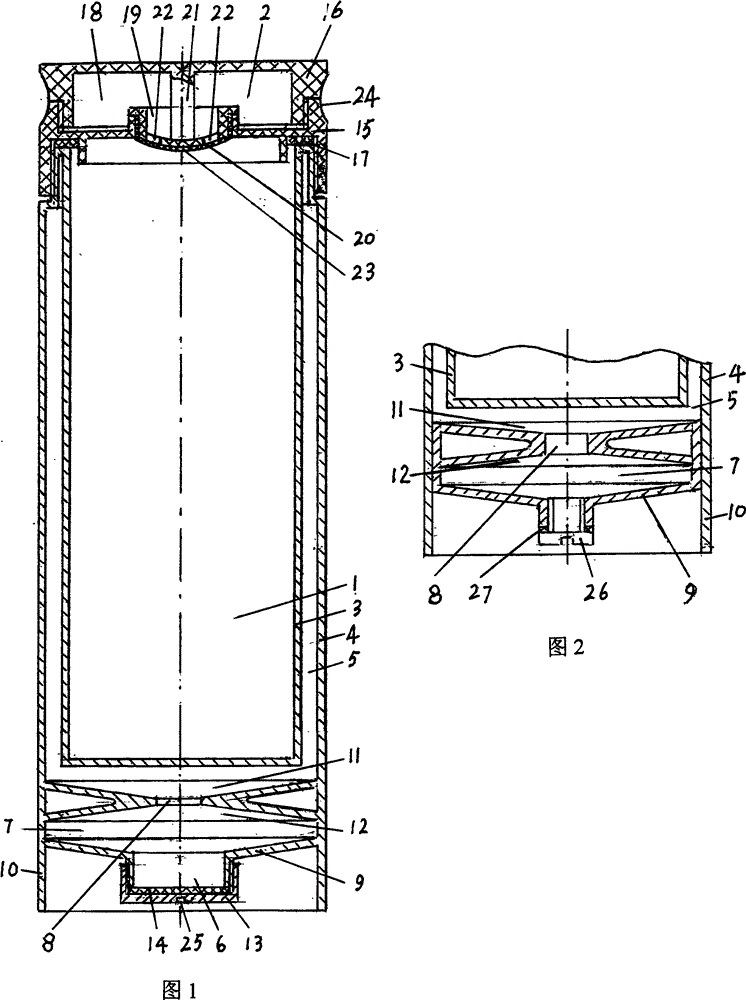

[0030] The thermos cup of embodiment 1 is as figure 1 shown. A thermos cup according to the present invention comprises a cup body 1 and a cup cover 2, the cup body 1 includes an inner layer 3, an outer shell 4 and a gap layer 5 between the inner layer 3 and the outer shell 4, the outer shell 4 is provided with a pouring hole 6, the gap The lower part of the layer 5 is provided with a breath fluid cavity 7, and the interstitial fluid cavity 7 has communication holes 8 communicating with the upper part of the interstitial layer 5. The small volume of breathing liquid cavity 7 is 1 / 5th of inner layer 3 volumes. Breathing liquid chamber 7 is a rotating breathing liquid chamber 7 . The casing 4 has a concave bottom surface 9 and a skirt 10 , and the pouring hole 6 is arranged on the concave bottom surface 9 of the casing 4 . The volume of the casing 4 skirt 10 below the 6 openings of the pouring holes is equal to the volume of the set cooling water after deducting the occupied ...

Embodiment 2

[0035] The thermos cup of embodiment 2 is as figure 1 , figure 2 shown. The thermos cup of embodiment 2 is a variant of the thermos cup of embodiment 1, and its upper part is exactly the same as that of embodiment 1, only the lower part is different. The breath chamber 7 of the lower part of the gap layer 5 of the thermos cup in this example is made separately earlier and then pressed into the shell 4 and then the contact seam is welded. This also provides a manufacturing method. Breathing liquid chamber 7 has communication hole 8 and communicates with the upper part of interstitial layer 5 . Breathing liquid chamber 7 is a rotating breathing liquid chamber 7 . Both the inflow surface 11 and the outflow surface 12 of the breath liquid chamber 7 are conical surfaces, which facilitate the circulation of cooling water in the breath liquid chamber 7 and the upper part of the interstitial layer 5 . The volume of the breath chamber 7 is less than one-fifth of the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com