Method and device for measuring a volume flow of a liquid flowing into a container and/or a volume of the liquid having flowed into the container

A technology of volume flow and inflow liquid, applied in volume measurement instruments/methods, measuring flow/mass flow, detecting fluid flow by measuring differential pressure, etc. Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

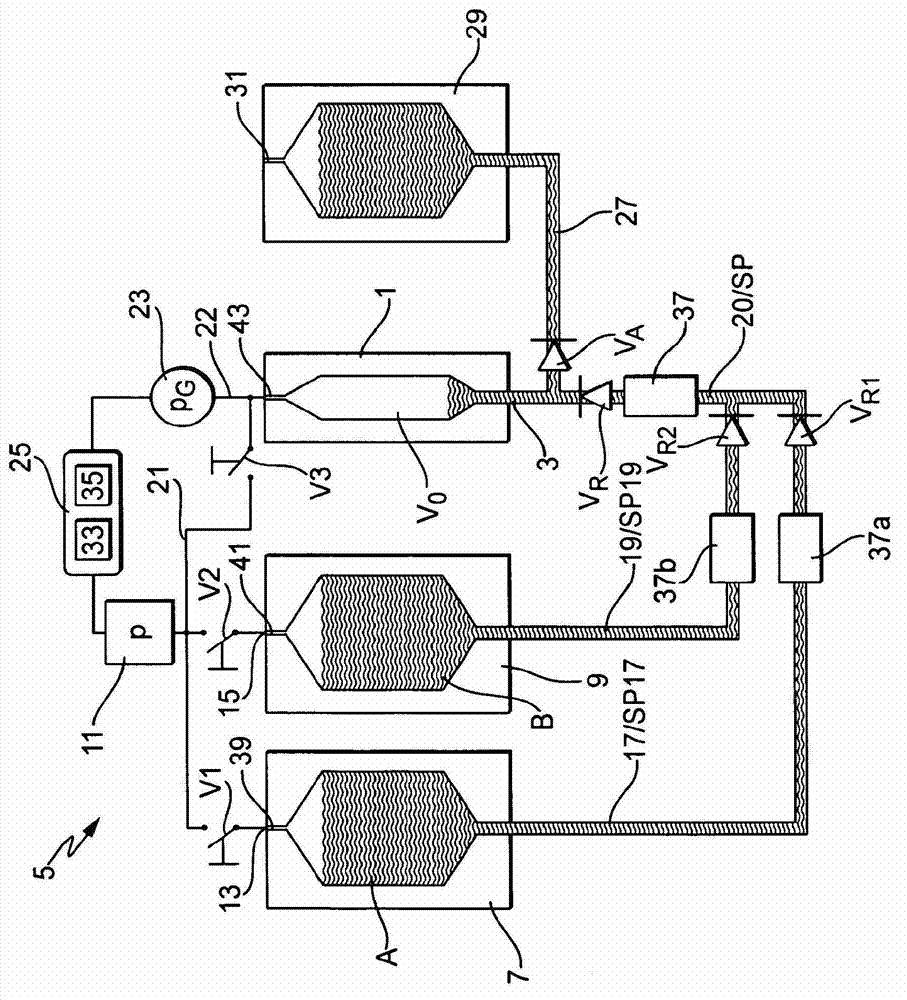

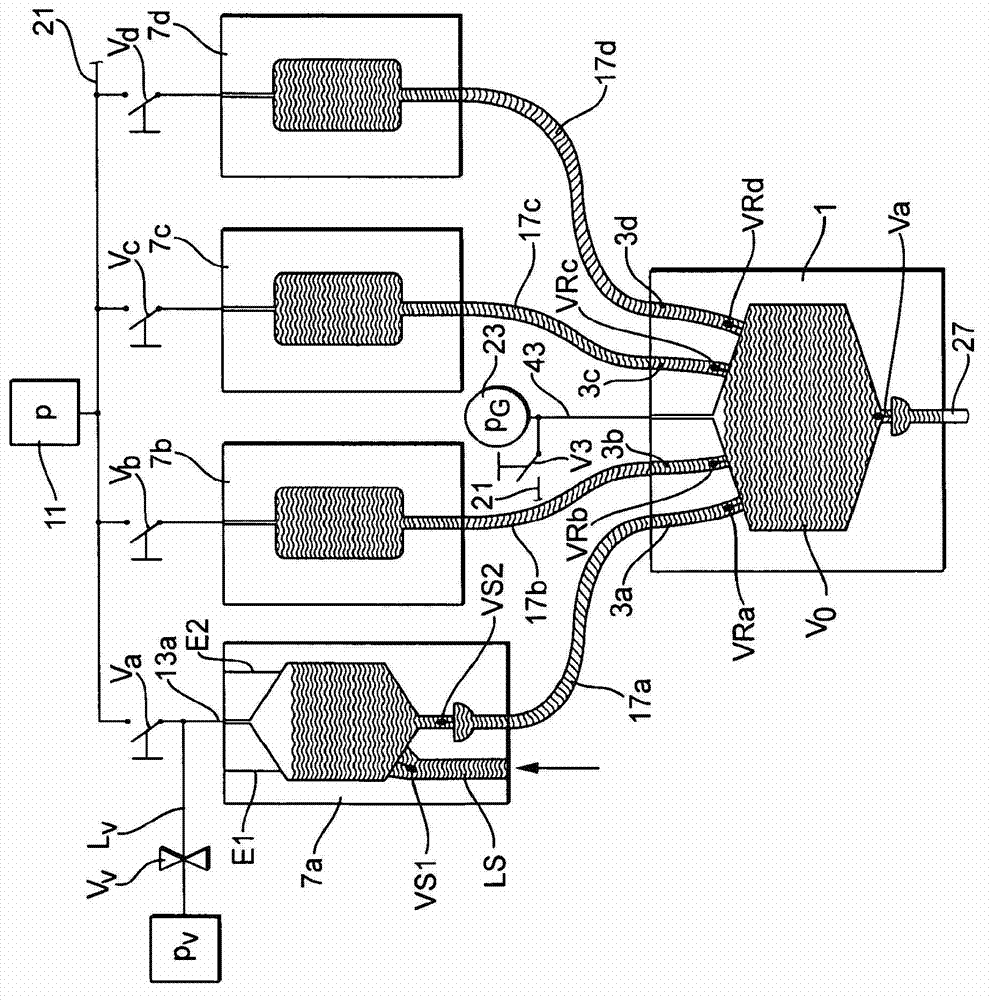

[0079] figure 1 The device of the present invention for measuring the volume flow dV(t) / dt of the liquid flowing into the container 1 and / or the volume V(t) of the liquid having flowed into the container 1 is shown.

[0080] The device includes a liquid supply system 5 connected to a filling opening 3 of the container 1, which opens into the interior of the container 1. The liquid supply system 5 is used to supply liquid to the container 1. The supply system 5 includes at least one storage unit 7, 9 filled with spare liquid A, B. The storage units 7, 9 are, for example, supply containers containing various liquids to be analyzed or they contain supplementary liquids required for analysis, such as reagent solutions. Liquids A, B can be contained in storage units 7, 9, for example, the storage units 7, 9 are in the form of a flexible gas and liquid impermeable volume, such as a bag of plastic foil or film such as polyethylene or polypropylene. The storage units 7, 9 are preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com