Micro thread linear motor based on magnetostrictive effect

A technology of magnetostrictive and linear motors, which is applied in the field of drive motors and micro-threaded linear motors. It can solve the problems of high drive voltage, low efficiency, and small deformation of piezoelectric materials, and achieve low drive voltage, high efficiency, and deformation. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

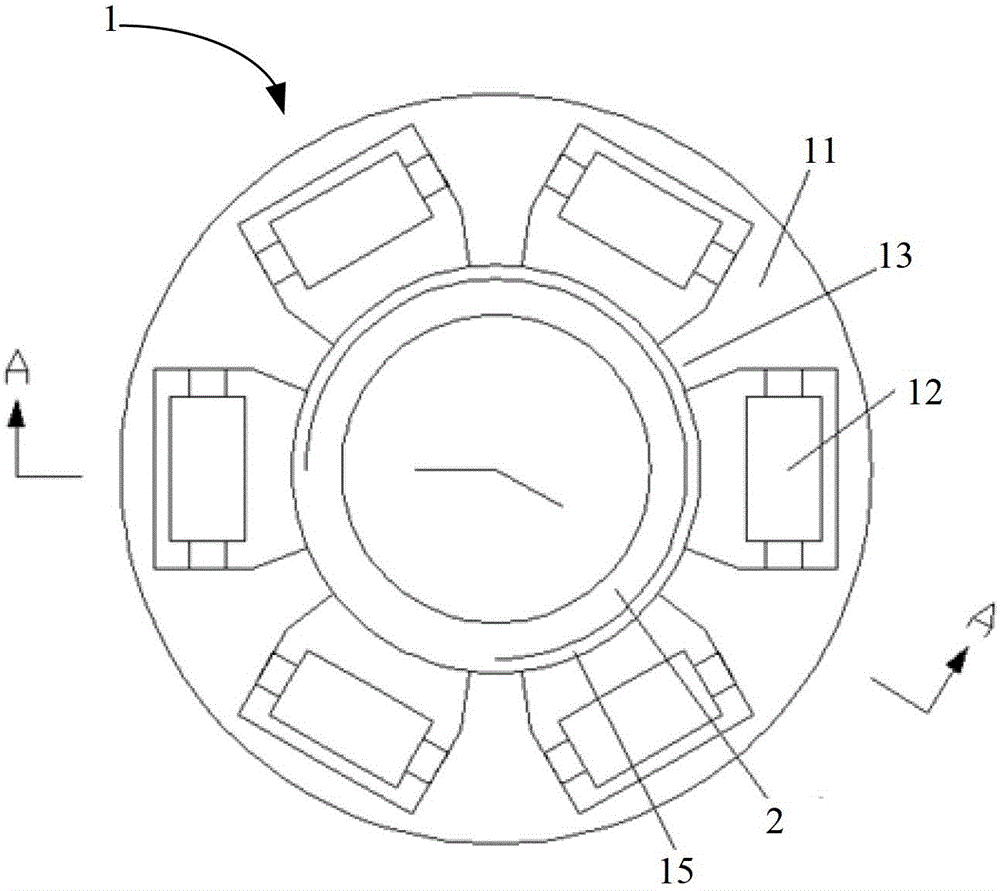

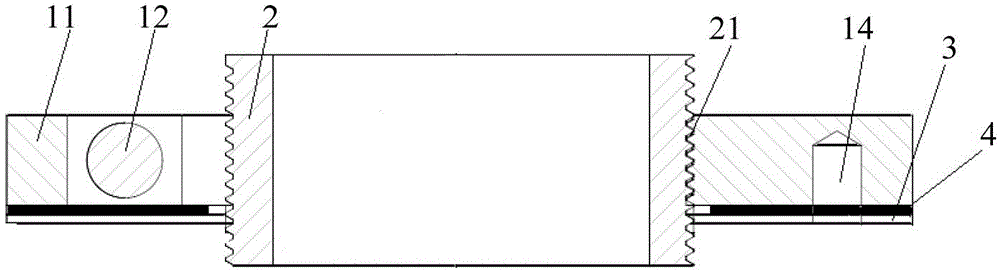

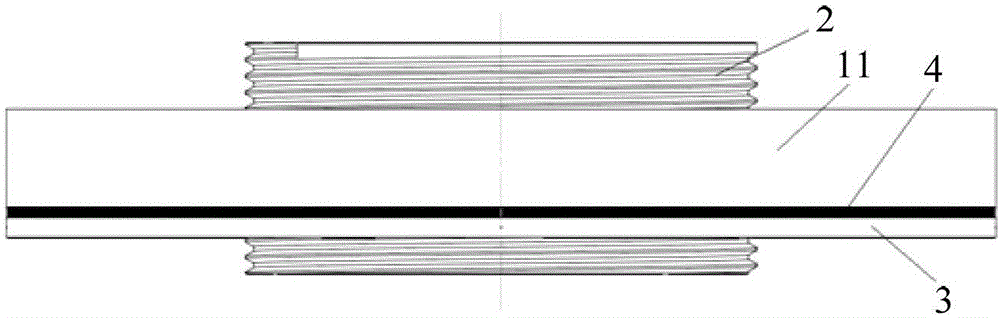

[0030] Such as figure 1 As shown, the threaded linear motor based on the magnetostrictive effect of the present embodiment includes a stator 1, a rotor 2 and an end cover 3, and the stator 1 includes a stator base 11 and 6 giant magnetostrictive units 12, and the stator base 11 is provided with 6 The giant magnetostrictive unit 12 is respectively arranged in each groove, and the protruding part between each two adjacent grooves forms a driving foot 13, and the inside of the stator base is provided with a screw thread 15, and the top is uniformly provided with 6 third grooves. Two threaded holes 14. The interior of the rotor 2 is a hollow structure, on which a thread pair 21 is arranged, which penetrates through the center of the stator base 11 and is threadedly connected with the stator base 11 through the thread 15 and the thread pair 21, and the end cover 3 adopts a ring sheet, which is connected to At the bottom of the stator base 11, six first threaded holes 31 are unifor...

Embodiment 2

[0039] see Figure 8 , in this embodiment, the stator 1 includes a stator base 11 and four giant magnetostrictive units 12, the stator base 11 is provided with four grooves, and the giant magnetostrictive units 12 are respectively arranged in each groove. When the motor is excited, along the clockwise direction, the first two giant magnetostrictive units sequentially apply two-phase sinusoidal excitation signals with a phase difference of π / 2 or negative π / 2, and the two-phase excitation signals of the last two giant magnetostrictive units The signals are in turn identical to the previous two-phase excitation signals. Except for the difference between the above and the first embodiment, and the number of the corresponding driving feet, the number of the first threaded hole and the number of the second threaded hole are all four, other components and compositions of this embodiment are the same as those of the first embodiment , which will not be described here.

[0040] Comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com