Upward spinning type melt electrostatic spinning device using rotary shaft with embossment as emitter

A melt electrospinning and launching device technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of complex devices and the influence of development speed, and achieve the goal of reducing critical voltage and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below

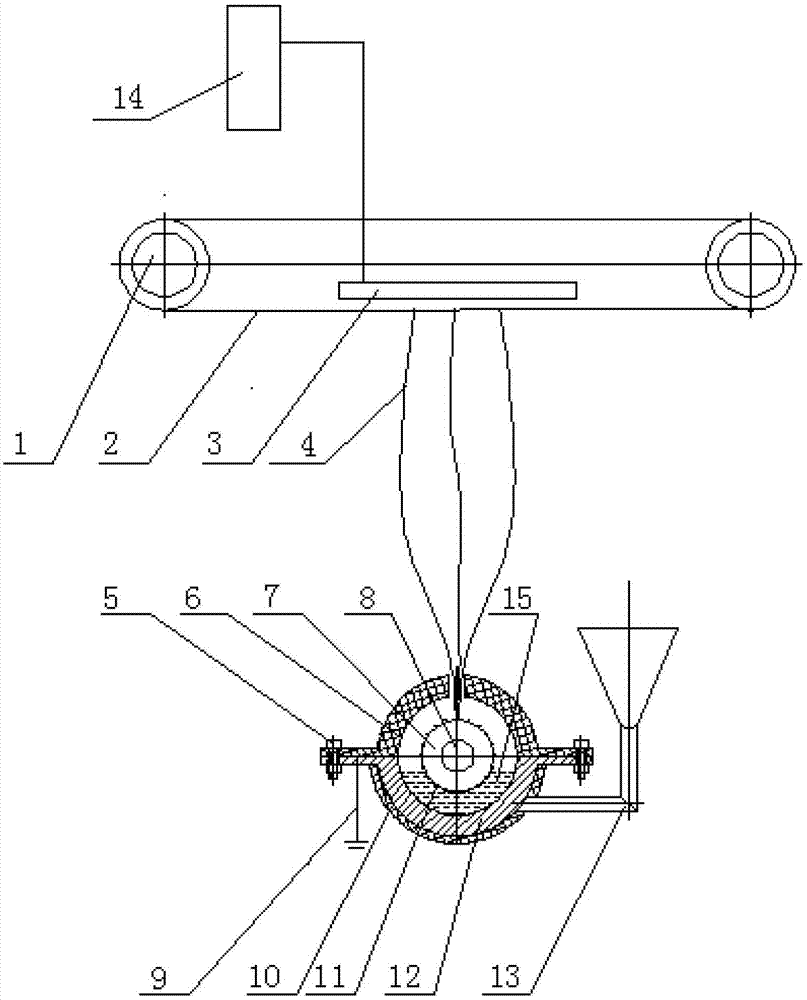

[0010] The invention mainly includes a transmitting device, a receiving device and an electrostatic generator.

[0011] The launching device includes a sealing cover connecting bolt (5), an upper sealing cover (6), a rotating shaft (7) with a protrusion (11), a heating rod (8), a lower sealing cover (12), and a feeding device (13). Among them, the heating rod (8) is located in the rotating shaft (7) with protrusions, and the heating rod (8) is required not to rotate, and the right end of the heating rod (8) is matched with the stepped hole in the rotating shaft (7) with protrusions to heat The left end of the rod (8) is threadedly connected with the heating rod holder, so that the heating rod does not rotate with the raised rotating shaft (7). The sealing cover consists of two parts, the upper sealing cover (6) and the lower sealing cover (12). There is a rectangular hole on the top of the upper sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com