Moisture-curable antifouling coating composition

A moisture-curing, composition technology, used in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., to solve problems such as unusability, no chemical bond formation, and lack of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

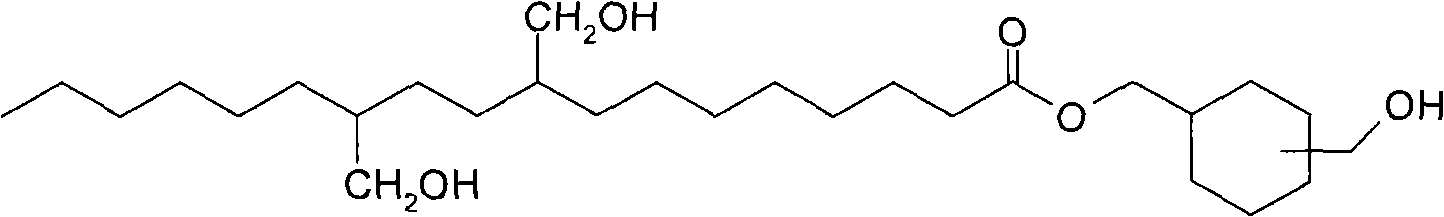

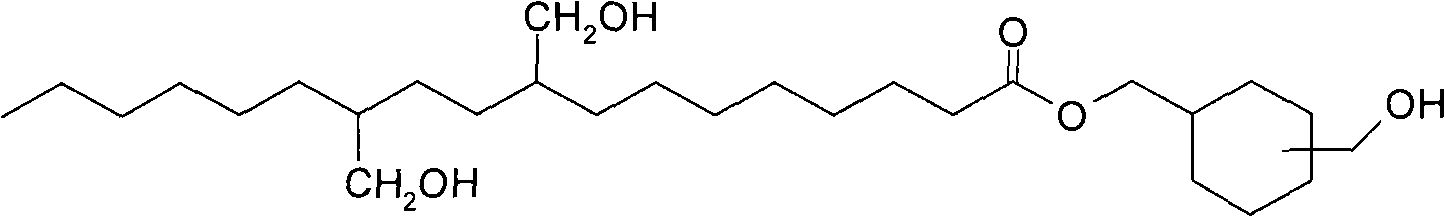

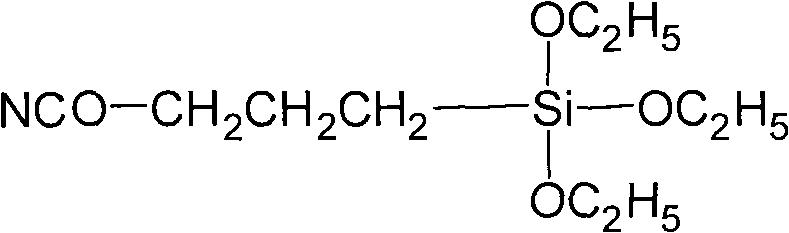

[0090] 3.4 g of Gen 4 NOP1 with a hydroxyl equivalent weight of 170 g / mol and 0.93 g of carbo-hydroxyl-terminated PDMS (MCR-C62, with a hydroxyl equivalent weight of 2500 g / mol) were charged into a 250 mL round bottom flask and stirred mechanically. 5.3 grams of 3-isocyanatopropyltriethoxysilane (IPTES, 95% purity) and 4 grams of butyl acetate (analytical grade) were added to the round bottom flask. The mixture was stirred at 75°C under nitrogen protection. 0.1% by weight of dibutyltin dilaurate (DBTDL) catalyst was added. Continue to react until the characteristic peak of the isocyanate functional group in the infrared analysis spectrum disappears.

[0091] 5 grams of a silane-terminated NOP / PDMS solution (70% solids content) was mixed with 0.2% by weight p-toluenesulfonic acid. The solution was stirred uniformly for 20 minutes. Remove the thoroughly mixed solution from the mixer and let it sit for 2-5 minutes to remove most air bubbles. The above formulation components w...

Embodiment 2

[0103] In this example, silane-terminated polyurethane and silane-terminated polysiloxane were synthesized separately and then blended together to obtain a moisture-cured antifouling coating component.

[0104] Charge 3.4 g of Gen4NOP 1 into a 50 mL round bottom flask equipped with a mechanical stirrer. 5.2 grams of IPTES and 3.7 grams of butyl acetate were added to the round bottom flask. The mixture was stirred at 75°C under nitrogen protection. 0.1% by weight of DBTDL was added. Continue to react until the characteristic peak of the isocyanate functional group in the infrared analysis spectrum disappears.

[0105] Charge 25 g of MCR-C62 into a 100 mL round bottom flask equipped with a mechanical stirrer. 2.6 grams of IPTES was added to the round bottom flask. The mixture was stirred at 75°C under nitrogen protection. 0.1% by weight of DBTDL was added. Continue to react until the characteristic peak of the isocyanate functional group in the infrared analysis spectrum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com