Wire winding and straightening mechanism of water tank wire-drawing machine

A water tank wire drawing machine and straightening technology, which is applied in the direction of metal wire drawing, straightening equipment, metal processing equipment, etc., can solve the problems of ultra-fine steel wire residual stress, etc., to eliminate internal residual stress, improve product performance and market competitiveness, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

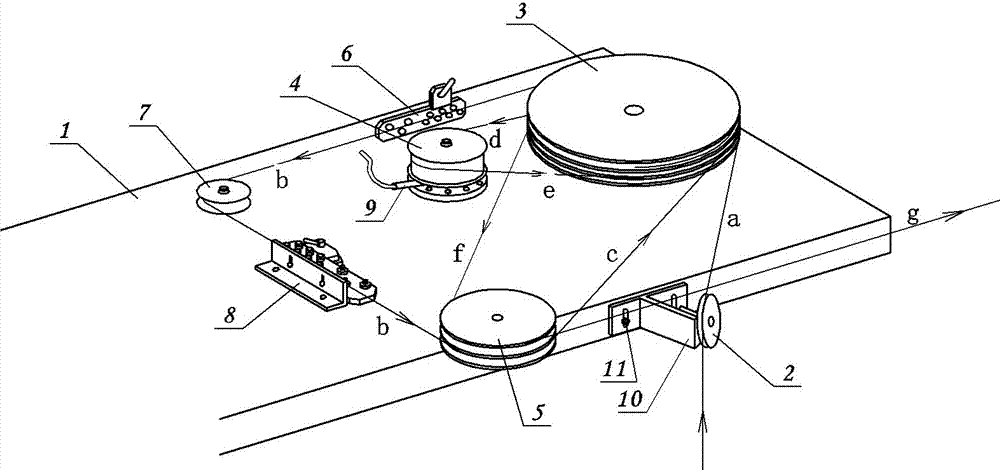

[0010] Example 1: see figure 1 The take-up and straightening mechanism of the water tank wire drawing machine is that the outlet guide wheel 2 is fixed on one side of the water tank wire drawing machine cover 1, and the outlet guide wheel 2 is installed on the support 10, which is between the support 10 and the side of the water tank wire drawing machine cover 1. A height adjustment mechanism is arranged between them, and the height adjustment mechanism is provided with a vertical adjustment hole on the support 10, and a locking bolt is arranged on the side of the water tank wire drawing machine upper cover. The upper cover 1 of the water tank wire drawing machine is respectively provided with a large tension wheel 3, a middle tension wheel 5 and a small tension wheel 4, and is fixed with a horizontal straightener 6 and a longitudinal straightener 8, and the two straighteners are arranged between Guide wheel 7. figure 1 The a, b, c, d, e, f, g in the above are the order of ou...

Embodiment 2

[0011] Example 2: see figure 1 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a driving device is arranged below the large tension wheel 3, an encoder is installed on the small tension wheel 4, and the output line 9 of the encoder is connected to the The input terminal of the controller is connected, and the output terminal of the controller is connected with the control terminal or power supply terminal of the driving device of the large tension wheel. The speed of the large tension wheel is determined by collecting the speed of the ultra-fine steel wire to ensure that the speeds in the process are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com